Rope drives are effective mechanical power transmission systems that use ropes running over pulleys to transfer motion between shafts. Known for their flexibility and ability to handle multiple drives simultaneously, they are commonly utilized in industries where smooth and quiet operation is crucial. Discover how rope drives can optimize Your machinery by reading the full article.

Table of Comparison

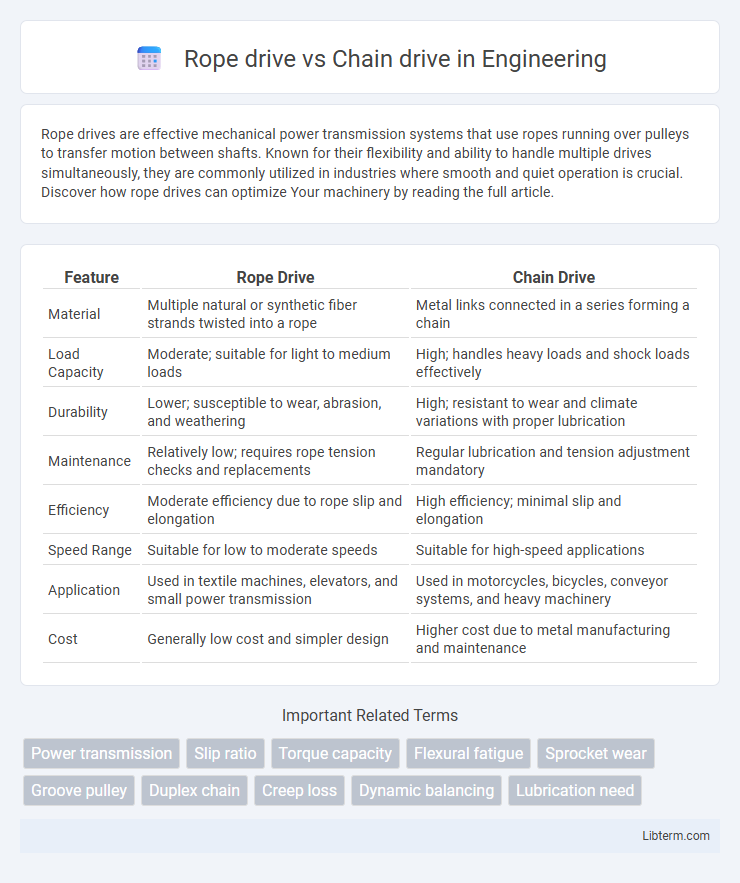

| Feature | Rope Drive | Chain Drive |

|---|---|---|

| Material | Multiple natural or synthetic fiber strands twisted into a rope | Metal links connected in a series forming a chain |

| Load Capacity | Moderate; suitable for light to medium loads | High; handles heavy loads and shock loads effectively |

| Durability | Lower; susceptible to wear, abrasion, and weathering | High; resistant to wear and climate variations with proper lubrication |

| Maintenance | Relatively low; requires rope tension checks and replacements | Regular lubrication and tension adjustment mandatory |

| Efficiency | Moderate efficiency due to rope slip and elongation | High efficiency; minimal slip and elongation |

| Speed Range | Suitable for low to moderate speeds | Suitable for high-speed applications |

| Application | Used in textile machines, elevators, and small power transmission | Used in motorcycles, bicycles, conveyor systems, and heavy machinery |

| Cost | Generally low cost and simpler design | Higher cost due to metal manufacturing and maintenance |

Introduction to Rope Drive and Chain Drive

Rope drive transmits power through one or more ropes running over grooved pulleys, ideal for long-distance power transfer with minimal slip and noise. Chain drive employs a series of linked metal chains and sprockets, offering high torque transmission suitable for heavy machinery and vehicles. Both systems vary in efficiency, maintenance, and application, where rope drives excel in large industrial setups and chain drives dominate in automotive and conveyor mechanisms.

Key Differences Between Rope Drive and Chain Drive

Rope drives use twisted fiber or wire ropes to transmit power, providing smooth and quiet operation with low maintenance, while chain drives utilize metal chains that offer higher strength and durability for heavy-duty applications. Rope drives are limited by their lower load-carrying capacity and susceptibility to wear from moisture, whereas chain drives excel in high-torque environments but require regular lubrication and adjustment. The choice between rope and chain drives depends on factors such as load requirements, environmental conditions, and maintenance preferences.

Advantages of Rope Drive Systems

Rope drive systems offer several advantages over chain drives, including smoother and quieter operation due to the flexibility and elasticity of ropes, which reduces vibration and noise levels. They require less maintenance because ropes do not need lubrication and are less prone to wear from corrosion compared to metal chains. Furthermore, rope drives are capable of transmitting power over longer distances with higher efficiency and can accommodate slight misalignments between pulleys without significant performance loss.

Advantages of Chain Drive Systems

Chain drive systems offer high efficiency in power transmission, typically reaching up to 98%, making them ideal for precise mechanical applications. Their ability to handle high torque loads and resistance to slippage ensures consistent performance in demanding industrial environments. Moreover, chain drives require less maintenance compared to rope drives, providing longer service life and greater durability under heavy-duty conditions.

Applications of Rope Drive in Industry

Rope drives are widely used in mining, construction, and material handling industries due to their ability to transmit power over long distances with minimal maintenance. They are ideal for heavy load hoisting applications such as elevators, cranes, and cable cars, where flexibility and shock absorption are crucial. Compared to chain drives, rope drives offer smoother operation, reduced noise levels, and superior resistance to environmental factors like dust and moisture.

Common Uses of Chain Drive Mechanisms

Chain drive mechanisms are commonly used in bicycles, motorcycles, and industrial machinery due to their ability to transmit high torque efficiently over moderate distances. They excel in applications requiring precise speed ratios and durability, such as conveyor systems and automotive timing chains. Chain drives offer low maintenance and reliable power transfer in environments where slip-free operation is essential.

Durability and Maintenance Comparison

Rope drives exhibit higher durability due to their resistance to corrosion and ability to operate smoothly under varying loads, requiring minimal maintenance compared to chain drives. Chain drives demand regular lubrication and tension adjustments to prevent wear and elongation, which can compromise performance over time. The maintenance frequency and susceptibility to environmental factors make rope drives more favorable for long-term durability in demanding applications.

Efficiency and Power Transmission Analysis

Rope drives typically offer higher efficiency in power transmission due to lower friction losses and smoother operation compared to chain drives, which experience more mechanical friction and wear. Chain drives provide reliable torque transfer and can handle higher load capacities but often suffer from energy losses due to chain tension and lubrication requirements. Efficiency in rope drives can reach up to 95%, while chain drives generally operate between 85% and 90%, impacting the overall power transmission performance in industrial applications.

Cost Considerations: Rope Drive vs Chain Drive

Rope drives typically have lower initial costs compared to chain drives due to simpler materials and manufacturing processes, making them cost-effective for lightweight applications. Chain drives, while more expensive upfront, offer greater durability and require less frequent replacement, reducing long-term maintenance expenses. Evaluating total life-cycle costs reveals that rope drives are suitable for budget-sensitive, low-torque needs, whereas chain drives provide better value in heavy-duty, high-torque environments.

Choosing the Right Drive System for Your Needs

Selecting the right drive system depends on load capacity, efficiency, and maintenance requirements. Rope drive systems excel in smooth power transmission and low noise for moderate loads, while chain drives offer higher torque capacity and durability in heavy-duty applications. Consider environmental conditions, cost-effectiveness, and service intervals to optimize system performance and longevity.

Rope drive Infographic

libterm.com

libterm.com