Fatigue load refers to the repeated or fluctuating stresses materials experience during service, which can lead to progressive structural damage and eventual failure over time. Understanding the mechanisms behind fatigue load is crucial for designing durable components in industries like aerospace, automotive, and civil engineering. Discover how proper analysis of fatigue load can enhance your design's longevity by reading the rest of the article.

Table of Comparison

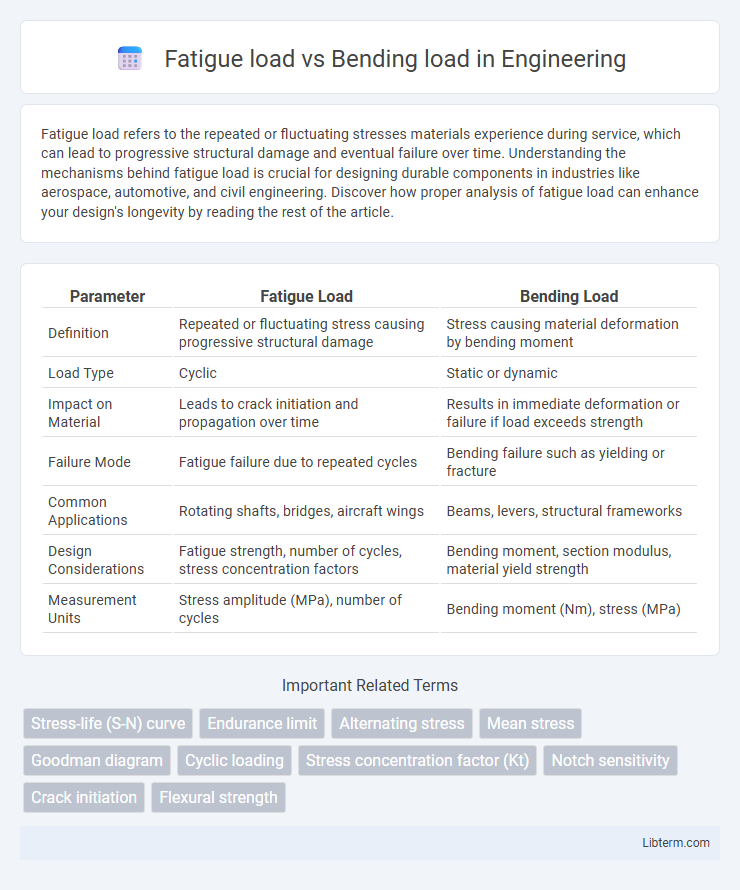

| Parameter | Fatigue Load | Bending Load |

|---|---|---|

| Definition | Repeated or fluctuating stress causing progressive structural damage | Stress causing material deformation by bending moment |

| Load Type | Cyclic | Static or dynamic |

| Impact on Material | Leads to crack initiation and propagation over time | Results in immediate deformation or failure if load exceeds strength |

| Failure Mode | Fatigue failure due to repeated cycles | Bending failure such as yielding or fracture |

| Common Applications | Rotating shafts, bridges, aircraft wings | Beams, levers, structural frameworks |

| Design Considerations | Fatigue strength, number of cycles, stress concentration factors | Bending moment, section modulus, material yield strength |

| Measurement Units | Stress amplitude (MPa), number of cycles | Bending moment (Nm), stress (MPa) |

Introduction to Mechanical Loads

Fatigue load refers to the repetitive or fluctuating stresses that cause progressive structural damage over time, leading to material failure even when the stress level is below the material's ultimate strength. Bending load involves a force applied perpendicular to the longitudinal axis of a component, causing it to bend and generate tension on one side and compression on the other. Understanding these mechanical loads is crucial for designing components that withstand dynamic stresses and prevent unexpected failures in engineering applications.

Defining Fatigue Load

Fatigue load refers to the repetitive or cyclic stress applied to a material or structure, causing progressive and localized damage that can lead to failure over time, even if the loads are below the material's ultimate tensile strength. This type of loading contrasts with bending load, which involves a single or static force causing deformation by bending. Understanding fatigue load is crucial in engineering design to predict the lifespan of components subjected to fluctuating forces, such as bridges, aircraft wings, and rotating machinery parts.

Understanding Bending Load

Bending load refers to the force applied perpendicular to a structural member, causing it to bend or flex, which creates tension on one side and compression on the other. Understanding bending load is crucial for designing beams, bridges, and other structures to ensure they can withstand the stress without permanent deformation or failure. Proper analysis of bending stresses helps in selecting materials and cross-sectional shapes that optimize strength and durability under expected loads.

Key Differences Between Fatigue and Bending Loads

Fatigue load refers to the repetitive or cyclic stresses that cause progressive material failure over time, whereas bending load involves a single or static force causing deformation by bending. Fatigue load is critical in evaluating the lifespan of materials subjected to fluctuating forces, while bending load primarily assesses the immediate strength and stiffness of a component. Understanding these key differences is essential for accurate structural analysis and design in engineering applications.

Material Behavior Under Fatigue Loading

Fatigue load induces progressive and localized structural damage through cyclic stresses, significantly affecting material microstructure and leading to crack initiation and propagation over time. Bending load generates a combination of tensile and compressive stresses on the material's surface, causing immediate deformation that may initiate failure if the stress exceeds the material's yield strength. Material behavior under fatigue loading is characterized by decreased fatigue strength and endurance limit due to repeated stress cycles, which differs from the response to static bending loads that focus primarily on instantaneous elastic and plastic deformation.

Structural Response to Bending Loads

Fatigue load refers to repetitive or cyclic stresses that cause progressive and localized structural damage, leading to crack initiation and growth over time, while bending load is a static or dynamic force causing deformation due to bending moments in structural members. Structural response to bending loads involves stress distribution across the cross-section, with the highest tensile and compressive stresses occurring at the outer fibers, potentially leading to material yielding or failure. Understanding the interplay between fatigue loads and bending stresses is crucial for designing resilient structures that withstand cyclic bending without premature failure.

Failure Mechanisms: Fatigue vs. Bending

Fatigue load induces failure through the progressive growth of micro-cracks caused by cyclic stress fluctuations, leading to eventual fracture even under stress levels below the material's ultimate tensile strength. Bending load causes failure primarily by exceeding the material's yield strength, resulting in plastic deformation and sudden fracture due to high tensile stress on the convex side of the bend. Understanding these distinct failure mechanisms is crucial for designing components to withstand cyclic loading versus static bending stresses.

Testing Methods for Fatigue and Bending Loads

Fatigue load testing typically involves cyclic loading using servo-hydraulic test machines to simulate repeated stress over time, measuring material durability and crack initiation under varying magnitudes and frequencies. Bending load testing is commonly conducted through three-point or four-point bending tests, applying static forces to assess material stiffness, strength, and failure points under bending stress. Both testing methods utilize strain gauges and data acquisition systems for precise measurement and analysis of stress-strain responses.

Engineering Applications and Case Studies

Fatigue load refers to the repetitive or fluctuating stress imposed on materials or structures over time, crucial in assessing the durability of engineering components such as bridges, aircraft wings, and automotive parts. Bending load, characterized by forces causing bending moments and deflections in beams or shafts, is essential in designing structural elements in construction and mechanical systems. Engineering case studies demonstrate that components subjected to fatigue loads often experience crack initiation and propagation, while bending load analysis ensures structural integrity under static or dynamic forces, emphasizing the need for accurate load modeling to prevent failure.

Design Strategies to Mitigate Load-Induced Failures

Design strategies to mitigate fatigue load and bending load failures emphasize material selection with high fatigue strength and stiffness to resist cyclic stresses and deformation. Employing geometric optimization, such as fillets and stress concentrator reduction, helps distribute stresses evenly under bending loads, enhancing durability. Surface treatments like shot peening and coatings increase fatigue resistance by inducing compressive residual stresses and improving wear properties in critical regions.

Fatigue load Infographic

libterm.com

libterm.com