A hydraulic hand pump provides precise control and reliable pressure generation for various industrial and mechanical applications. Its compact design and manual operation ensure portability and ease of use without the need for external power sources. Explore the rest of the article to discover how this tool can enhance your hydraulic system's efficiency and performance.

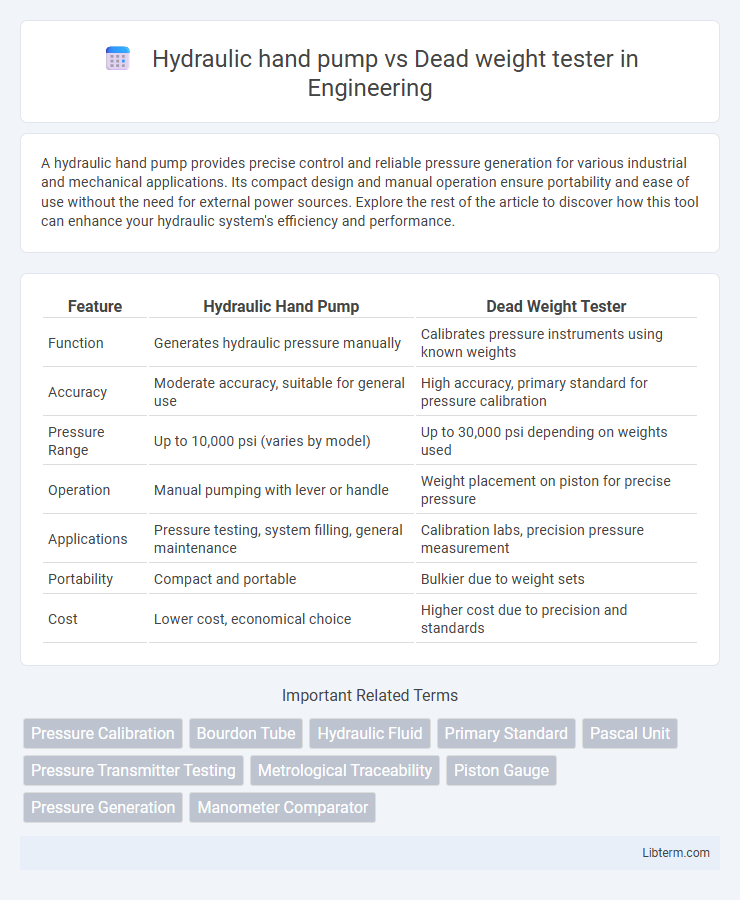

Table of Comparison

| Feature | Hydraulic Hand Pump | Dead Weight Tester |

|---|---|---|

| Function | Generates hydraulic pressure manually | Calibrates pressure instruments using known weights |

| Accuracy | Moderate accuracy, suitable for general use | High accuracy, primary standard for pressure calibration |

| Pressure Range | Up to 10,000 psi (varies by model) | Up to 30,000 psi depending on weights used |

| Operation | Manual pumping with lever or handle | Weight placement on piston for precise pressure |

| Applications | Pressure testing, system filling, general maintenance | Calibration labs, precision pressure measurement |

| Portability | Compact and portable | Bulkier due to weight sets |

| Cost | Lower cost, economical choice | Higher cost due to precision and standards |

Introduction to Hydraulic Hand Pumps and Dead Weight Testers

Hydraulic hand pumps generate controlled pressure by manual operation, making them essential tools for calibrating pressure instruments in various industrial applications. Dead weight testers provide precise pressure calibration by applying known weights to a piston, ensuring accurate and traceable pressure measurements. Both devices are fundamental in maintaining high accuracy standards in pressure testing and calibration processes.

Principle of Operation: Hydraulic Hand Pump vs Dead Weight Tester

A hydraulic hand pump operates by manually generating fluid pressure through a piston, creating a controlled hydraulic force transmitted to the test device. In contrast, a dead weight tester relies on precisely calibrated weights placed on a piston to produce a known, constant pressure based on gravitational force. The hydraulic hand pump offers adjustable pressure through manual pumping, while the dead weight tester provides direct pressure calibration via physical mass and piston area, ensuring high accuracy in pressure measurement.

Key Applications and Use Cases

Hydraulic hand pumps are primarily used for generating high-pressure fluid in portable calibration and testing applications, such as pressure gauge calibration in industrial maintenance and field service environments. Dead weight testers provide highly accurate pressure measurement and calibration by applying known weights to generate precise pressure, commonly utilized in laboratory settings and calibration laboratories for standards verification. Both tools serve critical roles in pressure calibration, with hand pumps favored for mobility and versatility while dead weight testers excel in precision and traceability.

Accuracy and Calibration Standards

Hydraulic hand pumps provide pressure generation with moderate accuracy, typically suitable for field calibration tasks, whereas dead weight testers offer superior precision by using calibrated masses to apply exact pressures, ensuring traceability to primary standards. Dead weight testers meet stringent calibration standards such as ISO/IEC 17025 and ASTM E74, delivering accuracy within +-0.01% of full scale, while hydraulic hand pumps generally achieve lower accuracy levels around +-0.1% to +-0.5%. Calibration reliability in dead weight testers stems from their mechanical design and periodic verification against national standards, making them the preferred choice for laboratory-grade pressure calibration.

Portability and Ease of Use Comparison

Hydraulic hand pumps offer superior portability due to their compact size and lightweight design, making them ideal for field calibration and on-site pressure testing. Dead weight testers, while providing highly accurate calibration through precise weight application, are generally bulkier and less convenient to transport. Ease of use favors hydraulic hand pumps as they require minimal setup and simpler operation, whereas dead weight testers demand careful handling and calibration procedures that can be time-consuming.

Maintenance Requirements and Durability

Hydraulic hand pumps require regular inspection of seals and fluid levels to prevent leaks and ensure optimal performance, with maintenance typically involving fluid replacement and seal lubrication. Dead weight testers possess high durability due to their solid construction but need precise calibration and clean, uncontaminated weights to maintain accuracy over time. Both devices demand maintenance to guarantee reliability, yet hydraulic hand pumps generally require more frequent attention compared to the robust, longer-lasting dead weight testers.

Pressure Range Capabilities

Hydraulic hand pumps typically offer pressure ranges from 0 to 10,000 psi, making them suitable for a broad spectrum of industrial applications requiring moderate to high pressure generation. Dead weight testers excel in precision pressure calibration with pressure ranges extending up to 100,000 psi, providing highly accurate and stable pressure references. The choice depends on the required pressure range and accuracy, with hydraulic hand pumps favored for versatile field use and dead weight testers preferred for laboratory-grade calibration.

Cost Analysis and Budget Considerations

Hydraulic hand pumps typically offer a lower upfront cost and are suitable for smaller budgets and portable applications, making them ideal for basic pressure testing tasks. Dead weight testers, while more expensive initially due to their precision components and calibration standards, provide superior accuracy and long-term reliability, which can reduce costs associated with recalibration and maintenance. For budget-conscious projects, choosing between these tools depends on weighing initial expenditure against the value of accuracy, durability, and maintenance frequency.

Advantages and Limitations of Each Device

Hydraulic hand pumps offer portability and ease of use, making them ideal for on-site pressure testing and calibration with moderate accuracy and pressure ranges up to 10,000 psi. Dead weight testers provide superior precision and reliability by using calibrated weights to generate exact pressures, making them the standard for high-accuracy laboratory calibration but are bulkier and less portable. While hydraulic hand pumps are cost-effective and simple, they lack the traceable accuracy and stability of dead weight testers, which require careful handling and periodic calibration of weights.

Choosing the Right Pressure Calibration Tool

Selecting the right pressure calibration tool depends on accuracy requirements and application complexity. Hydraulic hand pumps offer portability and ease of use for general pressure testing, while dead weight testers provide superior precision by applying known masses to generate reference pressures. For critical calibration tasks demanding traceable measurement standards, dead weight testers are the preferred choice, whereas hydraulic hand pumps suit routine field calibrations.

Hydraulic hand pump Infographic

libterm.com

libterm.com