Adhesive-bonded joints create strong, durable connections between materials without the need for mechanical fasteners, distributing stress evenly across the joint surface. This technique enhances the performance and longevity of assemblies in industries ranging from aerospace to automotive manufacturing. Discover how optimizing adhesive bonding can improve Your projects by exploring the full article.

Table of Comparison

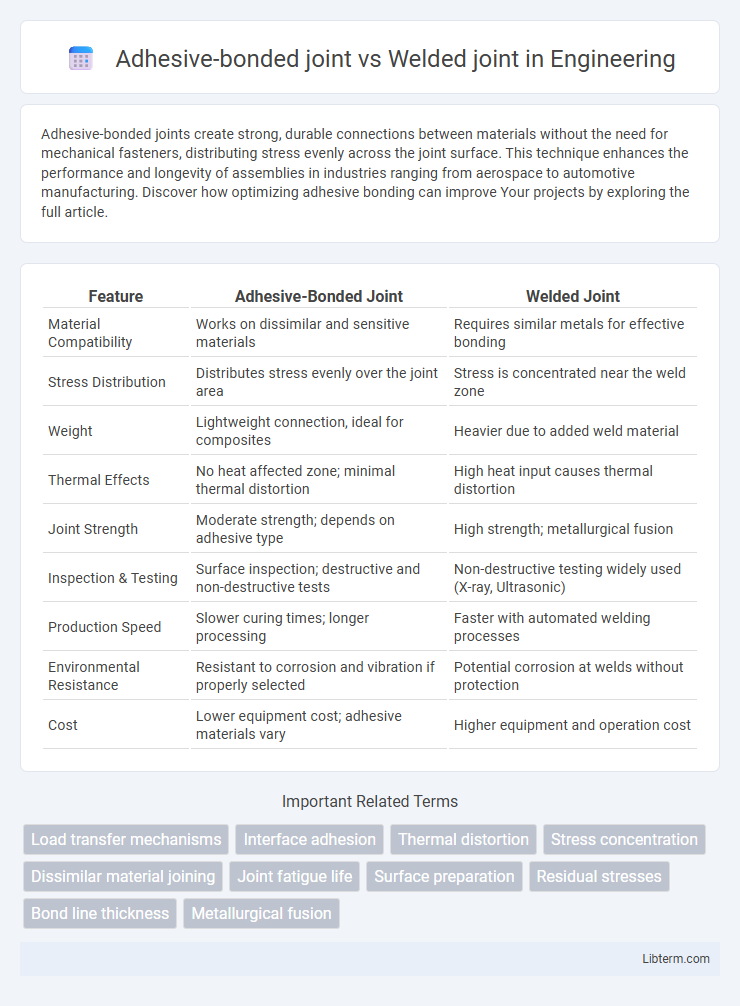

| Feature | Adhesive-Bonded Joint | Welded Joint |

|---|---|---|

| Material Compatibility | Works on dissimilar and sensitive materials | Requires similar metals for effective bonding |

| Stress Distribution | Distributes stress evenly over the joint area | Stress is concentrated near the weld zone |

| Weight | Lightweight connection, ideal for composites | Heavier due to added weld material |

| Thermal Effects | No heat affected zone; minimal thermal distortion | High heat input causes thermal distortion |

| Joint Strength | Moderate strength; depends on adhesive type | High strength; metallurgical fusion |

| Inspection & Testing | Surface inspection; destructive and non-destructive tests | Non-destructive testing widely used (X-ray, Ultrasonic) |

| Production Speed | Slower curing times; longer processing | Faster with automated welding processes |

| Environmental Resistance | Resistant to corrosion and vibration if properly selected | Potential corrosion at welds without protection |

| Cost | Lower equipment cost; adhesive materials vary | Higher equipment and operation cost |

Introduction to Adhesive-Bonded and Welded Joints

Adhesive-bonded joints use chemical agents to join surfaces by creating molecular attraction between substrates, offering advantages like uniform stress distribution and the ability to bond dissimilar materials. Welded joints involve the fusion of metals by melting, providing high strength and structural integrity, ideal for load-bearing applications. Both methods serve distinct industrial purposes, with adhesive bonding favored for lightweight or complex assemblies and welding preferred for robust, permanent connections.

Fundamental Principles of Joining Methods

Adhesive-bonded joints utilize chemical bonding and mechanical interlocking to join materials by distributing stresses across the bonded area, providing enhanced fatigue resistance and vibration damping. Welded joints rely on melting and solidification processes to create a metallurgical bond between materials, resulting in high strength and rigidity but potential thermal distortion. Understanding the fundamental principles such as surface preparation, load transfer mechanisms, and environmental resistance is critical for selecting the appropriate joining method in engineering applications.

Materials Compatibility: Adhesive vs Welding

Adhesive-bonded joints offer superior compatibility with dissimilar materials such as metals, composites, and plastics, enabling stress distribution without causing thermal distortion or metallurgical changes. Welding typically requires materials with similar melting points and chemical compositions to achieve a strong, reliable bond, limiting its use with dissimilar metals and causing potential issues like residual stress and corrosion. Adhesives provide enhanced flexibility in joining materials with differing thermal expansion coefficients, which often pose challenges in welded joints.

Strength and Load-Bearing Capabilities

Adhesive-bonded joints provide uniform stress distribution and excellent fatigue resistance, making them ideal for joining dissimilar materials where load distribution is critical. Welded joints typically offer higher immediate strength and are preferred for heavy load-bearing applications due to their metal fusion properties. Strength and load-bearing capabilities depend on factors like material compatibility, joint design, and environmental conditions, with adhesives excelling in vibration damping and welds dominating in structural rigidity.

Durability and Resistance to Environmental Factors

Adhesive-bonded joints exhibit superior resistance to corrosion and fatigue under cyclic loading compared to welded joints, making them more durable in harsh environmental conditions such as exposure to moisture and chemicals. Welded joints, while providing higher mechanical strength, often suffer from stress concentrations and susceptibility to cracking due to thermal distortion and oxidation during the welding process. The choice between adhesive bonding and welding depends on application demands, with adhesives preferred for mitigating galvanic corrosion and welding favored for high-load structural components.

Process Complexity and Application Techniques

Adhesive-bonded joints require meticulous surface preparation and precise application of adhesives, often involving curing times and controlled environmental conditions, making the process more complex than welding. Welded joints rely on skilled manipulation of heat and filler materials to fuse metals directly, offering faster execution but demanding rigorous safety measures and specialized equipment. Application techniques for adhesive bonding prioritize uniform adhesive distribution and pressure control, whereas welding focuses on weld bead quality and avoiding defects like cracks or porosity.

Cost Considerations and Economic Impact

Adhesive-bonded joints typically involve lower initial equipment costs and reduced energy consumption compared to welded joints, making them cost-effective for lightweight materials and complex shapes. Welded joints often require specialized labor and higher operational costs due to intense heat application and post-processing treatments, impacting overall project budgets significantly. Long-term economic impact favors adhesive bonding in applications demanding corrosion resistance and stress distribution, whereas welding excels in structural strength needs but may incur higher maintenance expenses.

Common Industry Applications

Adhesive-bonded joints find widespread use in aerospace, automotive, and electronics industries due to their ability to join dissimilar materials while providing uniform stress distribution and corrosion resistance. Welded joints are prevalent in heavy construction, shipbuilding, and pipeline industries where high strength, durability, and load-bearing capacity are critical requirements. Industry selection between these methods depends on factors such as material type, mechanical load, environmental exposure, and production speed.

Advantages and Limitations: Comparative Analysis

Adhesive-bonded joints offer superior stress distribution and the ability to join dissimilar materials without heat distortion, making them ideal for lightweight and composite structures, but they can be sensitive to surface preparation and environmental degradation. Welded joints provide high strength and durability with excellent mechanical properties suitable for heavy-duty applications, yet they often cause thermal distortion and residual stresses, limiting their use on heat-sensitive materials. Both techniques require specific expertise and equipment, with adhesive bonding favoring design flexibility and corrosion resistance, while welding ensures robust structural integrity in metal assemblies.

Choosing the Right Joint for Engineering Applications

Adhesive-bonded joints provide excellent stress distribution and are ideal for joining dissimilar materials or thin components without heat distortion, making them suitable for aerospace and automotive industries. Welded joints offer superior strength and thermal conductivity, preferred in heavy structural applications involving metals such as steel and aluminum. Selecting the right joint depends on factors like load conditions, material compatibility, environmental exposure, and production efficiency to ensure optimal performance and durability in engineering applications.

Adhesive-bonded joint Infographic

libterm.com

libterm.com