Cavitation occurs when rapid changes in pressure cause vapor bubbles to form and collapse in a liquid, often leading to damage on surfaces such as pumps or propellers. This phenomenon not only reduces equipment efficiency but also increases maintenance costs and operational downtime. Discover how understanding cavitation can help you prevent costly damage and improve the longevity of your machinery by reading the full article.

Table of Comparison

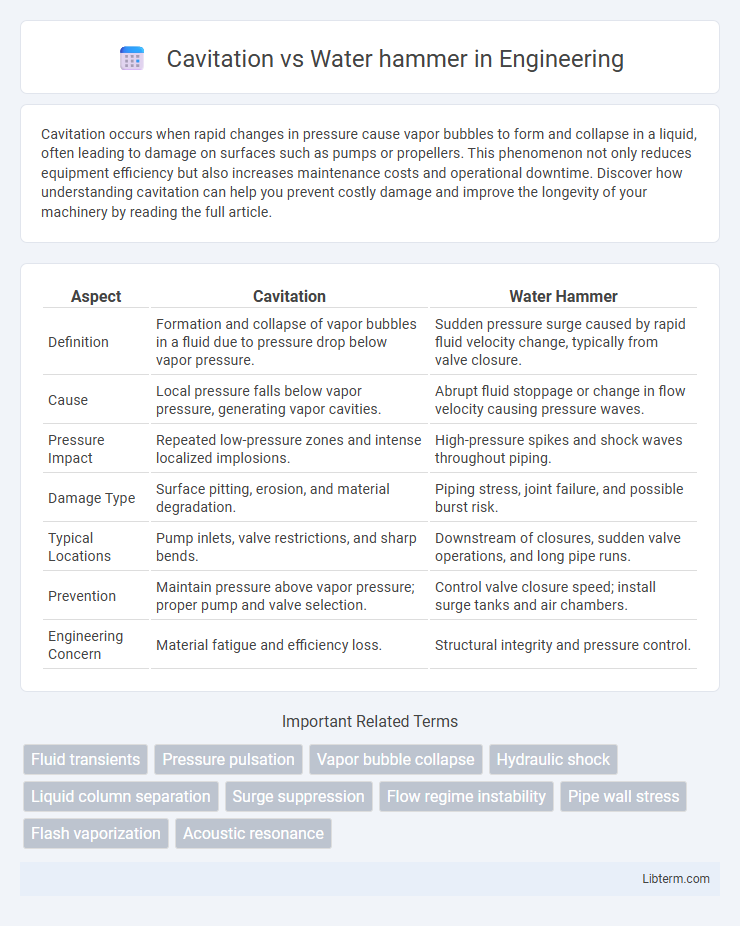

| Aspect | Cavitation | Water Hammer |

|---|---|---|

| Definition | Formation and collapse of vapor bubbles in a fluid due to pressure drop below vapor pressure. | Sudden pressure surge caused by rapid fluid velocity change, typically from valve closure. |

| Cause | Local pressure falls below vapor pressure, generating vapor cavities. | Abrupt fluid stoppage or change in flow velocity causing pressure waves. |

| Pressure Impact | Repeated low-pressure zones and intense localized implosions. | High-pressure spikes and shock waves throughout piping. |

| Damage Type | Surface pitting, erosion, and material degradation. | Piping stress, joint failure, and possible burst risk. |

| Typical Locations | Pump inlets, valve restrictions, and sharp bends. | Downstream of closures, sudden valve operations, and long pipe runs. |

| Prevention | Maintain pressure above vapor pressure; proper pump and valve selection. | Control valve closure speed; install surge tanks and air chambers. |

| Engineering Concern | Material fatigue and efficiency loss. | Structural integrity and pressure control. |

Understanding Cavitation: Definition and Causes

Cavitation occurs when vapor bubbles form in a liquid due to local drops in pressure below the liquid's vapor pressure, causing damage when these bubbles collapse. It commonly arises in pumps, propellers, and valves where rapid pressure changes cause vapor cavities to develop. Understanding cavitation involves recognizing factors such as high flow velocity, sudden pressure drops, and vapor pressure thresholds that contribute to bubble formation and subsequent material erosion.

What is Water Hammer? Key Concepts Explained

Water hammer is a pressure surge or shock wave that occurs when a fluid in motion is forced to stop or change direction suddenly, causing a rapid rise in pressure within the pipe system. This phenomenon commonly results from the abrupt closing of a valve or sudden pump shutdown, leading to potential damage like pipe bursts or joint failures. Understanding pressure wave propagation, fluid inertia, and pipe elasticity is crucial to designing systems that minimize water hammer effects and protect infrastructure integrity.

Physical Differences Between Cavitation and Water Hammer

Cavitation involves the formation and collapse of vapor bubbles in a liquid when local pressure drops below the vapor pressure, causing intense shock waves and potential material damage. Water hammer is a pressure surge caused by the sudden stoppage or change in flow velocity within a pipeline, generating high-pressure pulses that can stress pipes and valves. Unlike cavitation, which stems from vapor phase change, water hammer results from fluid momentum changes, making their physical origins and effects distinctly different.

Common Symptoms in Piping Systems

Common symptoms of cavitation in piping systems include loud knocking noises, vibration, and pitting damage on valve seats or pipe walls caused by the collapse of vapor bubbles. Water hammer typically presents with sudden pressure surges resulting in banging sounds, pipe vibration, and potential joint or support failure due to rapid fluid velocity changes. Both phenomena can lead to accelerated wear and potential system failure if not properly addressed.

Impact on Equipment and Infrastructure

Cavitation causes localized damage by forming vapor bubbles that collapse violently, leading to pitting and erosion on pump impellers, valves, and pipe surfaces, significantly reducing equipment lifespan. Water hammer generates high-pressure shock waves from sudden fluid velocity changes, causing pipe bursts, joint failures, and structural stress in pipelines and support systems. Both phenomena compromise infrastructure integrity but differ as cavitation deteriorates components internally, while water hammer induces mechanical shock and external structural damage.

Detection and Diagnosis Methods

Detection and diagnosis methods for cavitation primarily involve vibration analysis, acoustic emission monitoring, and pressure fluctuation measurement to identify the characteristic high-frequency signals and pressure drops associated with vapor bubble collapse. Water hammer detection relies on transient pressure sensors, high-speed pressure transducers, and flow rate monitoring to capture rapid pressure spikes and fluid momentum changes within pipelines. Advanced diagnostic techniques integrate real-time signal processing and pattern recognition algorithms to differentiate cavitation from water hammer events, ensuring accurate identification for effective maintenance and prevention.

Prevention Strategies for Cavitation

Cavitation prevention strategies center on maintaining adequate pressure levels above vapor pressure and minimizing abrupt pressure drops in fluid systems, achieved through proper pump selection, smooth piping design, and controlled flow velocities. Installing anti-cavitation valves and ensuring system components are free from blockages help reduce the risk of vapor bubble formation and collapse. Regular system maintenance, pressure monitoring, and the use of cavitation-resistant materials further enhance prevention efforts, distinguishing cavitation control from water hammer mitigation methods.

Mitigation Techniques for Water Hammer

Water hammer mitigation techniques include installing air chambers, surge tanks, and pressure relief valves to absorb pressure spikes in pipelines, thereby protecting pipe integrity and reducing noise. Properly sizing and positioning slow-closing valves and using variable frequency drives (VFDs) can also control flow velocity changes that cause water hammer. Regular system maintenance and routine inspections help identify and address conditions leading to water hammer, minimizing risk of pipe damage and operational disruptions.

Cost Implications and Maintenance Considerations

Cavitation in piping systems causes localized damage and frequent pump repairs, increasing maintenance costs due to erosion and component replacement. Water hammer induces sudden pressure surges that stress pipe joints and valves, leading to costly downtime and extensive system inspections. Both phenomena require investment in preventative measures such as pressure relief devices and regular system monitoring to minimize long-term financial impact.

Choosing the Right Protection for Your System

Cavitation and water hammer pose significant threats to piping systems, requiring distinct protection strategies to avoid costly damage. Cavitation protection involves maintaining proper pressure and flow conditions to prevent vapor bubble formation, typically using air chambers or surge tanks, while water hammer protection focuses on damping sudden pressure surges through devices like pressure relief valves and water hammer arrestors. Selecting the right protection depends on accurate system analysis, including flow velocity, pipe material, and pressure conditions, ensuring optimal device placement and minimizing downtime.

Cavitation Infographic

libterm.com

libterm.com