A Programmable Logic Controller (PLC) is an essential industrial automation device that controls machinery and processes through programmable software, enhancing efficiency and precision. It operates in real-time, making quick decisions based on input signals to regulate outputs in manufacturing environments. Discover how a PLC can optimize your automation systems by exploring the detailed insights in this article.

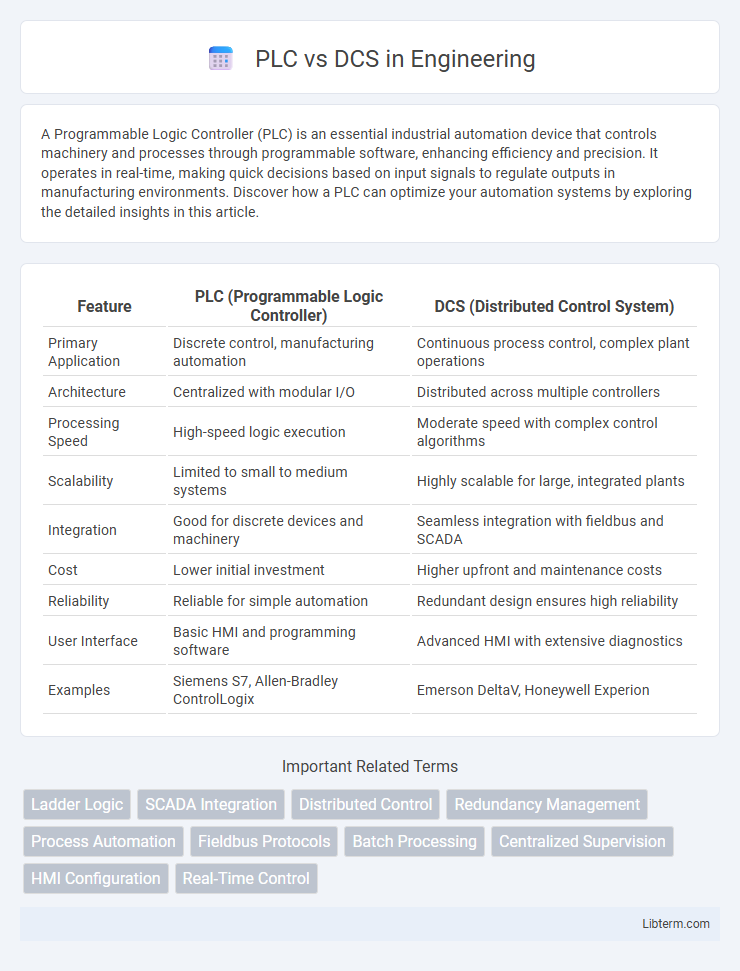

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | DCS (Distributed Control System) |

|---|---|---|

| Primary Application | Discrete control, manufacturing automation | Continuous process control, complex plant operations |

| Architecture | Centralized with modular I/O | Distributed across multiple controllers |

| Processing Speed | High-speed logic execution | Moderate speed with complex control algorithms |

| Scalability | Limited to small to medium systems | Highly scalable for large, integrated plants |

| Integration | Good for discrete devices and machinery | Seamless integration with fieldbus and SCADA |

| Cost | Lower initial investment | Higher upfront and maintenance costs |

| Reliability | Reliable for simple automation | Redundant design ensures high reliability |

| User Interface | Basic HMI and programming software | Advanced HMI with extensive diagnostics |

| Examples | Siemens S7, Allen-Bradley ControlLogix | Emerson DeltaV, Honeywell Experion |

Introduction to PLC and DCS

PLC (Programmable Logic Controller) is a digital computer used to automate industrial processes by controlling machinery through real-time inputs and outputs. DCS (Distributed Control System) integrates multiple control loops distributed across various control stations to manage complex, large-scale process environments. Both systems enhance operational efficiency, but PLC is favored for discrete automation tasks while DCS excels in continuous process control.

Defining PLC: Programmable Logic Controller

A Programmable Logic Controller (PLC) is a specialized industrial computer designed for real-time control and automation of manufacturing processes. PLCs are widely used for discrete control tasks, with capabilities for logic operations, sequencing, and timing in complex machinery environments. Their modular hardware and user-friendly programming interfaces enable rapid deployment and flexible integration in various industrial automation applications.

Understanding DCS: Distributed Control System

A Distributed Control System (DCS) is designed to control complex industrial processes by decentralizing control functions across multiple interconnected controllers. Unlike a Programmable Logic Controller (PLC) which is optimized for discrete control tasks, a DCS excels in managing continuous process variables such as temperature, pressure, and flow in industries like oil refining and power generation. The integration of advanced communication networks and real-time data analytics within a DCS enhances system reliability, scalability, and centralized monitoring capabilities.

Key Differences Between PLC and DCS

PLC (Programmable Logic Controller) excels in discrete control and rapid response for machinery automation, while DCS (Distributed Control System) is designed for complex process control across large-scale industrial plants, emphasizing reliability and scalability. PLC systems typically operate with centralized control units and are adaptable for modular expansions, whereas DCS features distributed control units with integrated feedback loops for continuous process monitoring. The core distinction lies in their application scope: PLCs serve specific automated tasks with high-speed execution, and DCS manages extensive processes requiring coordinated control and data acquisition.

Architecture Comparison: PLC vs DCS

PLC architecture features a modular design with centralized controllers that manage discrete processes through input/output modules, enabling rapid response and flexibility in automation tasks. DCS architecture utilizes a distributed control system with multiple interconnected controllers and operator workstations, providing enhanced scalability, redundancy, and real-time process monitoring across complex industrial environments. The key difference lies in PLC's focus on discrete control with simple hardware topology versus DCS's integrated, fault-tolerant network optimized for continuous process control and large-scale system management.

Application Areas: Where PLCs and DCS Excel

PLCs excel in discrete manufacturing processes, assembly lines, and machinery control where fast, real-time responses and modular scalability are essential. DCS systems are ideal for continuous, complex process industries such as chemical plants, oil refineries, and power generation due to their advanced process control, integration, and redundancy features. Both systems optimize industrial automation but target specific operational requirements and scale.

Scalability and Flexibility in Automation

PLCs offer high flexibility and scalability for automation systems with modular design enabling easy expansion and rapid adaptation to changing process requirements. DCS solutions provide robust scalability suitable for complex and large-scale industrial processes, delivering centralized control with seamless integration across multiple control loops. Both systems support scalable architectures but PLCs excel in flexible deployment for discrete controls, while DCS excels in continuous process automation with integrated data management.

Cost Analysis: Initial Investment and Maintenance

PLC systems generally have a lower initial investment cost compared to DCS due to their modular design and scalability, making them suitable for smaller or less complex automation projects. Maintenance expenses for PLCs tend to be lower as well, benefiting from standardized components and simpler troubleshooting processes, whereas DCS maintenance can be more costly due to integrated architecture and proprietary software requirements. Evaluating total cost of ownership involves considering equipment price, software licensing, training, and the complexity of system integration over the plant lifecycle.

Integration and Communication Capabilities

Programmable Logic Controllers (PLCs) offer flexible integration with various industrial networks such as Ethernet/IP, Modbus, and Profibus, enabling real-time control in discrete and batch processes. Distributed Control Systems (DCS) provide seamless communication through proprietary and standard protocols like FOUNDATION Fieldbus and OPC UA, optimizing continuous process automation with centralized data management. The choice between PLC and DCS depends on the scale of integration required, with PLCs excelling in modular, decentralized setups and DCS favoring tightly integrated, large-scale systems.

Choosing the Right System: Factors to Consider

Selecting between a PLC and DCS depends on the complexity and scale of the control system required. PLCs excel in fast, discrete control applications with simpler architectures, while DCS offers superior integration for large-scale, continuous processes with extensive data handling and monitoring capabilities. Consider factors such as system size, process type, real-time control needs, scalability, and integration with existing infrastructure when choosing the appropriate automation solution.

PLC Infographic

libterm.com

libterm.com