Coacervation is a process where two liquid phases separate, resulting in the formation of a dense, colloidal-rich phase called coacervate droplets. This phenomenon is crucial in fields like drug delivery, food science, and cosmetics for encapsulating active ingredients or controlling release rates. Discover how coacervation can enhance your understanding of material science and practical applications by reading the rest of the article.

Table of Comparison

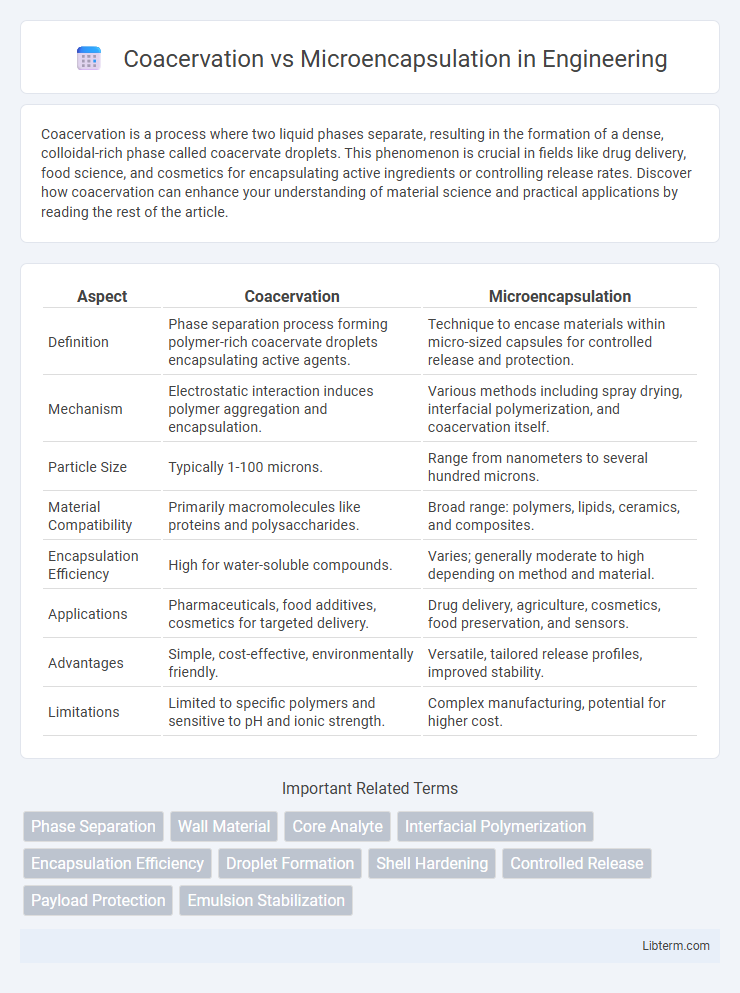

| Aspect | Coacervation | Microencapsulation |

|---|---|---|

| Definition | Phase separation process forming polymer-rich coacervate droplets encapsulating active agents. | Technique to encase materials within micro-sized capsules for controlled release and protection. |

| Mechanism | Electrostatic interaction induces polymer aggregation and encapsulation. | Various methods including spray drying, interfacial polymerization, and coacervation itself. |

| Particle Size | Typically 1-100 microns. | Range from nanometers to several hundred microns. |

| Material Compatibility | Primarily macromolecules like proteins and polysaccharides. | Broad range: polymers, lipids, ceramics, and composites. |

| Encapsulation Efficiency | High for water-soluble compounds. | Varies; generally moderate to high depending on method and material. |

| Applications | Pharmaceuticals, food additives, cosmetics for targeted delivery. | Drug delivery, agriculture, cosmetics, food preservation, and sensors. |

| Advantages | Simple, cost-effective, environmentally friendly. | Versatile, tailored release profiles, improved stability. |

| Limitations | Limited to specific polymers and sensitive to pH and ionic strength. | Complex manufacturing, potential for higher cost. |

Introduction to Coacervation and Microencapsulation

Coacervation is a phase separation process forming a polymer-rich coacervate phase used to encapsulate active ingredients, enhancing stability and controlled release. Microencapsulation involves coating or entrapping core materials within a micro-scale shell to protect sensitive substances and modulate release profiles. Both techniques are widely applied in pharmaceuticals, food technology, and cosmetics for targeted delivery and preservation of bioactive compounds.

Definition and Overview of Coacervation

Coacervation is a phase separation process where two liquid phases form, resulting in the encapsulation of core materials within a polymer-rich coacervate layer. It serves as a method for microencapsulation by producing microspheres or microcapsules that protect bioactive ingredients, control release, or improve stability. This technique involves complex coacervation, which uses interactions between oppositely charged polymers, and simple coacervation, relying on changes in temperature or solvent composition.

Understanding Microencapsulation

Microencapsulation involves enclosing active substances within a protective coating, enhancing stability, controlled release, and targeted delivery in pharmaceuticals, food, and cosmetics. Unlike coacervation, which is a phase separation process forming polymer-rich droplets, microencapsulation uses various techniques such as spray drying, liposomes, or polymer shell formation to achieve encapsulation. This method optimizes ingredient protection, improves shelf life, and ensures precise release profiles, critical in drug delivery systems and flavor preservation.

Mechanisms of Coacervation Process

Coacervation involves phase separation where polymer-rich droplets form in a solution through electrostatic interaction or solvent change, encapsulating active ingredients within a polymer shell. In contrast, microencapsulation encompasses various techniques, including coacervation, spray drying, and interfacial polymerization, designed to enclose substances within micro-scale capsules for controlled release. The mechanism of the coacervation process specifically relies on the attraction between oppositely charged polymers or temperature-induced polymer desolvation, leading to the formation of a coacervate phase that traps the core material effectively.

Types of Microencapsulation Techniques

Coacervation is a microencapsulation technique involving the phase separation of colloidal particles to form a coating around an active core, typically categorized into simple and complex coacervation based on the number of polymers used. Microencapsulation techniques also include spray drying, interfacial polymerization, and liposome entrapment, with each method selected according to the desired release profile, particle size, and core material properties. Understanding the physicochemical interactions and process parameters in these techniques optimizes encapsulation efficiency and stability for applications in pharmaceuticals, food, and agriculture.

Comparative Analysis: Coacervation vs Microencapsulation

Coacervation and microencapsulation are both advanced techniques used for encapsulating active ingredients, but they differ in mechanism and applications. Coacervation involves phase separation of polymers to form a coating around the core material, offering high encapsulation efficiency and controlled release, whereas microencapsulation typically uses physical or chemical processes to create a protective barrier, enabling enhanced stability and targeted delivery. Comparative analysis reveals coacervation is preferred for sensitive bioactives in pharmaceuticals, while microencapsulation suits food and agriculture for masking flavors and protecting nutrients.

Applications in Pharmaceuticals and Food Industry

Coacervation and microencapsulation are advanced techniques extensively utilized in pharmaceuticals and the food industry for controlled release and protection of active ingredients. In pharmaceuticals, coacervation provides efficient drug encapsulation for sustained release, enhancing bioavailability and stability of sensitive compounds. The food industry leverages microencapsulation to preserve flavors, nutrients, and probiotics, improving shelf life and masking undesirable tastes.

Advantages and Limitations of Coacervation

Coacervation offers precise control over capsule size and release profile, making it ideal for sensitive ingredient protection in pharmaceuticals and food industries. Its advantages include high encapsulation efficiency and mild processing conditions that preserve bioactive compounds. Limitations involve sensitivity to environmental changes such as pH and temperature, which can affect stability and scalability for large-scale production.

Benefits and Challenges of Microencapsulation

Microencapsulation offers targeted delivery and controlled release of active ingredients, enhancing product stability and shelf life across pharmaceuticals, food, and cosmetics. Its benefits include protection from environmental factors and masking unfavorable tastes or odors, while challenges involve high production costs, potential scalability issues, and ensuring uniform capsule size and release rates. Optimizing encapsulation techniques and materials remains critical to improving efficiency and performance in diverse applications.

Future Trends in Coacervation and Microencapsulation Technologies

Emerging trends in coacervation and microencapsulation technologies emphasize enhancing targeted drug delivery and controlled release mechanisms using advanced polymers and biocompatible materials. Innovations such as nano-coacervates and stimuli-responsive microcapsules are driving precision medicine and sustainable agriculture applications. Integration of artificial intelligence and machine learning is improving formulation optimization, enabling more efficient encapsulation processes with improved stability and functionality.

Coacervation Infographic

libterm.com

libterm.com