Rotameters provide accurate flow measurement by using a float inside a tapered tube, which rises or falls according to the flow rate, making them ideal for visual monitoring of liquid or gas flows. Turbine flow meters measure flow velocity with a rotor that spins proportionally to the fluid speed, offering precise, real-time data often used in industrial applications. Explore the differences between these flow meters to determine which best suits your specific measurement needs and operational conditions.

Table of Comparison

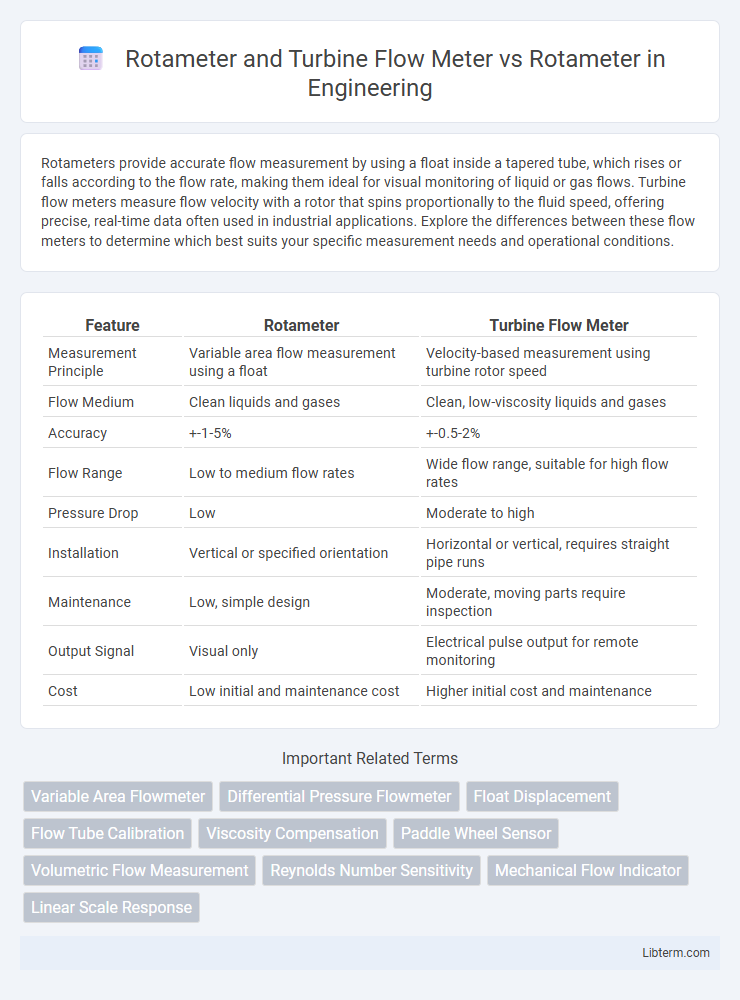

| Feature | Rotameter | Turbine Flow Meter |

|---|---|---|

| Measurement Principle | Variable area flow measurement using a float | Velocity-based measurement using turbine rotor speed |

| Flow Medium | Clean liquids and gases | Clean, low-viscosity liquids and gases |

| Accuracy | +-1-5% | +-0.5-2% |

| Flow Range | Low to medium flow rates | Wide flow range, suitable for high flow rates |

| Pressure Drop | Low | Moderate to high |

| Installation | Vertical or specified orientation | Horizontal or vertical, requires straight pipe runs |

| Maintenance | Low, simple design | Moderate, moving parts require inspection |

| Output Signal | Visual only | Electrical pulse output for remote monitoring |

| Cost | Low initial and maintenance cost | Higher initial cost and maintenance |

Introduction to Flow Measurement Technologies

Rotameters and turbine flow meters are essential technologies in flow measurement, with rotameters utilizing a variable area principle to provide visual flow rate readings typically for liquids and gases. Turbine flow meters operate based on the velocity of the fluid passing through a rotor, generating precise flow data ideal for clean, steady flow applications. Compared to rotameters, turbine flow meters offer higher accuracy and digital output compatibility, making them suitable for automated process control in industrial environments.

What is a Rotameter?

A Rotameter is a type of flow meter that measures the flow rate of liquids and gases using a tapered tube and a float that rises or falls in response to fluid flow, providing a visual indication of flow rate. Compared to Turbine Flow Meters, Rotameters offer a simple, low-maintenance design without moving parts exposed to the fluid, making them ideal for low to moderate flow applications. Turbine Flow Meters deliver higher accuracy and better performance in high-velocity and clean fluid environments but require power supply and more maintenance.

Principles of Rotameter Operation

The Rotameter operates on the principle of variable area flow measurement, where a float rises in a tapered tube in response to the fluid flow rate, providing a direct visual indication of flow. Turbine Flow Meters, in contrast, measure flow based on the angular velocity of a rotor spun by the fluid passing through it, converting mechanical rotation into electrical signals for flow calculation. Compared to Turbine Flow Meters, the Rotameter's simple design offers ease of use and maintenance but may be less suitable for high-pressure or high-temperature applications.

Overview of Turbine Flow Meters

Turbine flow meters measure fluid velocity through the rotational speed of a turbine wheel placed in the flow stream, providing high accuracy and fast response for clean, low-viscosity fluids. Compared to rotameters, which rely on a floating indicator in a tapered tube to measure flow rate, turbine flow meters offer better precision and digital output options, suitable for demanding industrial applications. Their compact design and minimal pressure drop make turbine flow meters ideal for monitoring water, oil, and gas flow in pipelines requiring reliable, real-time measurement data.

How Turbine Flow Meters Work

Turbine flow meters operate by measuring the velocity of fluid flowing through a pipe using a rotor with blades that spin at a rate proportional to the flow velocity. The rotational speed of the turbine is detected via magnetic or optical sensors, converting the mechanical motion into an electrical signal for accurate flow rate calculation. Compared to rotameters, which rely on a float rising in a tapered tube to indicate flow rate visually, turbine flow meters provide precise digital output, making them suitable for automated systems requiring high accuracy and repeatability.

Rotameter vs Turbine Flow Meter: Key Differences

Rotameters use a float inside a tapered tube to measure flow based on variable area principles, offering simplicity and direct visual readings. Turbine flow meters employ a rotor that spins proportional to flow velocity, providing high accuracy and suitability for clean, low-viscosity fluids. The primary differences lie in measurement mechanism, accuracy, and application range, with turbine meters excelling in precision and rotameters favored for ease of use and cost-effectiveness.

Accuracy and Reliability Comparison

Turbine flow meters offer higher accuracy and better repeatability compared to rotameters due to their precise rotor-based measurement mechanism, making them suitable for applications requiring detailed flow data. Rotameters provide reliable visual flow indication with moderate accuracy, benefiting from simple design and low maintenance but are less precise in fluctuating flow conditions. While turbine meters excel in fast response and digital integration, rotameters maintain consistent reliability in low-cost, low-tech settings.

Applications: Where Each Meter Excels

Rotameters excel in low to medium flow rate applications such as water treatment, chemical dosing, and HVAC systems due to their simplicity, reliability, and ease of maintenance. Turbine flow meters outperform rotameters in high-precision measurement scenarios including fuel flow monitoring, hydraulic testing, and lubrication oil measurement where accuracy and repeatability at variable flow conditions are critical. While rotameters are preferred for visual, direct-reading flow measurement in clean fluids, turbine flow meters are ideal for automated systems requiring electrical output and high-frequency flow data.

Installation and Maintenance Considerations

Rotameters require vertical installation to ensure accurate gravity-driven float movement, while turbine flow meters can be installed horizontally or vertically, offering greater flexibility in piping layouts. Maintenance of rotameters is minimal, mainly involving cleaning the tube and float inspection, whereas turbine flow meters need regular bearing and blade servicing to prevent wear and maintain accuracy. Choosing between the two depends on accessibility and maintenance capabilities, with rotameters favored for simplicity and turbine flow meters suited for high-flow, industrial applications.

Choosing the Right Flow Meter for Your Application

Selecting the right flow meter involves evaluating accuracy, measurement range, and fluid compatibility; rotameters provide simple, cost-effective visual flow indication for low to medium flow rates with transparent tubes, while turbine flow meters deliver highly accurate, high-frequency readings suited for clean, high-velocity liquids. Turbine flow meters excel in dynamic applications requiring precise flow rate data, featuring low pressure drop and digital output options that support integration with control systems. Consider process conditions, fluid properties, and desired data resolution to determine whether the traditional rotameter or the more advanced turbine flow meter best meets your application's performance and monitoring requirements.

Rotameter and Turbine Flow Meter Infographic

libterm.com

libterm.com