Maximum flow rate represents the highest volume of fluid or gas that can pass through a system or component within a given time, crucial for optimizing performance in pipelines, pumps, and filtration systems. Understanding this parameter helps you ensure efficiency, prevent overloading, and maintain safety across various applications. Explore the rest of the article to learn how to calculate and apply maximum flow rate effectively.

Table of Comparison

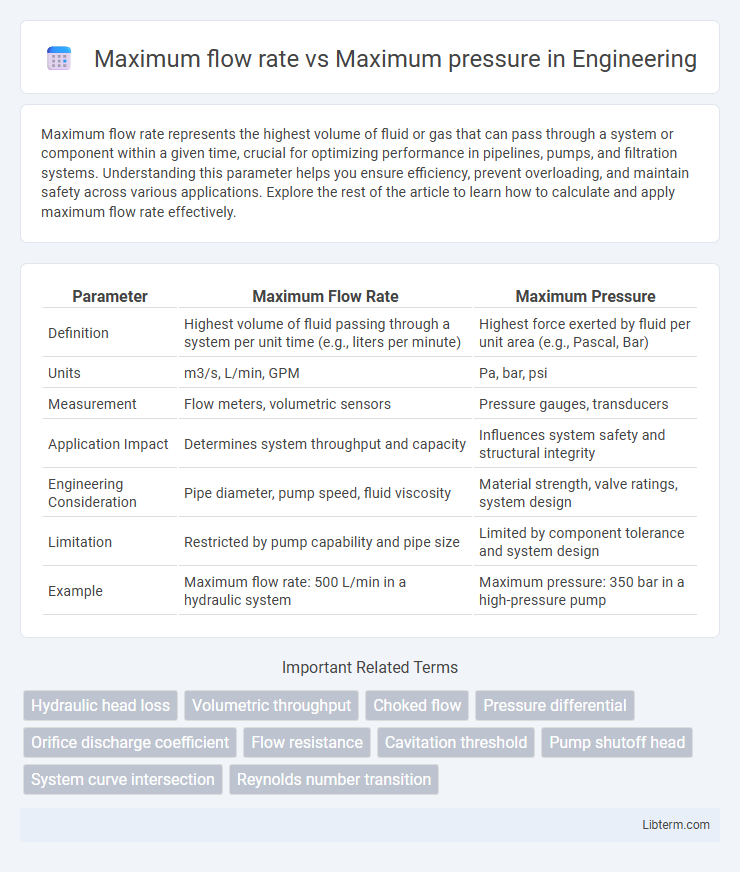

| Parameter | Maximum Flow Rate | Maximum Pressure |

|---|---|---|

| Definition | Highest volume of fluid passing through a system per unit time (e.g., liters per minute) | Highest force exerted by fluid per unit area (e.g., Pascal, Bar) |

| Units | m3/s, L/min, GPM | Pa, bar, psi |

| Measurement | Flow meters, volumetric sensors | Pressure gauges, transducers |

| Application Impact | Determines system throughput and capacity | Influences system safety and structural integrity |

| Engineering Consideration | Pipe diameter, pump speed, fluid viscosity | Material strength, valve ratings, system design |

| Limitation | Restricted by pump capability and pipe size | Limited by component tolerance and system design |

| Example | Maximum flow rate: 500 L/min in a hydraulic system | Maximum pressure: 350 bar in a high-pressure pump |

Understanding Maximum Flow Rate and Maximum Pressure

Maximum flow rate refers to the highest volume of fluid that can pass through a system per unit of time, often measured in liters per minute (L/min) or gallons per minute (GPM), while maximum pressure denotes the greatest force exerted by the fluid within the system, typically expressed in pascals (Pa) or pounds per square inch (psi). Understanding the relationship between maximum flow rate and maximum pressure is crucial for designing efficient fluid systems, as increasing pressure generally enables higher flow rates but may also demand stronger, more durable materials to prevent system failure. Accurate assessment of both parameters ensures optimal performance and safety in applications such as hydraulics, pneumatics, and water supply networks.

Key Differences Between Flow Rate and Pressure

Maximum flow rate measures the volume of fluid passing through a system per unit time, typically expressed in liters per minute (L/min) or gallons per minute (GPM), while maximum pressure refers to the highest force exerted by the fluid on the system walls, measured in pascals (Pa) or pounds per square inch (PSI). Flow rate determines the capacity to transport fluid, impacting system efficiency and delivery speed, whereas pressure influences the force available to overcome resistance and maintain fluid movement. Understanding these key differences is crucial for designing hydraulic and pneumatic systems that balance speed and power requirements.

How Flow Rate Affects System Performance

Maximum flow rate directly impacts system performance by determining the volume of fluid delivered per unit time, influencing cooling efficiency, hydraulic power, and overall throughput. Higher flow rates increase system responsiveness and can enhance heat transfer but may also lead to elevated pressure drops and potential energy losses within pipes or components. Balancing flow rate with maximum pressure ensures optimal pump performance and prevents system failures due to excessive stress or cavitation.

The Impact of Pressure on Fluid Systems

Maximum pressure in fluid systems directly influences the maximum flow rate by determining the driving force pushing the fluid through pipes or channels. As pressure increases, fluid velocity and flow rate typically rise until system constraints such as pipe diameter or valve capacity limit further flow escalation. Understanding the relationship between pressure and flow rate is critical for optimizing pump performance, preventing system failures, and ensuring efficient fluid transport in pipelines.

Relationship Between Flow Rate and Pressure

Maximum flow rate and maximum pressure have an inverse relationship governed by fluid dynamics principles, where increasing flow rate typically results in decreased pressure due to frictional losses and turbulence within a system. The Bernoulli equation and Darcy-Weisbach formula quantify how pressure drops occur as flow velocity rises in pipes or channels. Accurate system design requires balancing these parameters to optimize performance without exceeding equipment limits or causing fluid cavitation.

Factors Influencing Maximum Flow Rate

The maximum flow rate in fluid systems is primarily influenced by pipe diameter, fluid viscosity, and pressure differential across the system. While maximum pressure defines the upper limit of force exerted by the fluid, flow rate depends heavily on the system's capacity to maintain velocity and overcome frictional losses. Factors such as pipe roughness, length, and the presence of valves or fittings also significantly impact the achievable maximum flow rate.

Factors Affecting Maximum Pressure

Maximum pressure in fluid systems is influenced by factors such as pipe diameter, fluid viscosity, and system elevation changes, directly impacting the allowable maximum flow rate. Material strength and pump capacity determine the system's pressure limits, while friction losses and valve restrictions also reduce maximum pressure achievable. Understanding these variables ensures efficient design and safe operation within the pressure constraints of hydraulic and pneumatic systems.

Common Misconceptions About Flow and Pressure

Maximum flow rate and maximum pressure are often misunderstood as interchangeable measurements, but they represent distinct hydraulic properties; flow rate measures the volume of fluid moving per unit time, while pressure measures the force exerted by the fluid per unit area. A common misconception is that increasing pressure automatically increases flow rate, but flow depends on system resistance and pipe diameter, not just pressure. Engineers must consider both parameters independently to optimize fluid systems and avoid design inefficiencies.

Applications: Choosing the Right Parameters

Selecting the appropriate maximum flow rate and maximum pressure is critical for optimizing system performance in hydraulic and pneumatic applications. High maximum flow rates are essential for processes requiring rapid fluid movement, such as industrial cooling and irrigation systems, while maximum pressure parameters must be tailored to withstand operational stresses in applications like hydraulic presses or high-pressure gas delivery. Balancing these parameters ensures efficient energy use, safety compliance, and equipment longevity across varied industrial and engineering contexts.

Troubleshooting Flow Rate and Pressure Issues

Troubleshooting flow rate and pressure issues requires analyzing maximum flow rate alongside maximum pressure specifications to ensure system performance aligns with design parameters. Low flow rates despite adequate maximum pressure often indicate blockages, leaks, or faulty valves, while high pressure with reduced flow can signal pump malfunctions or pipe restrictions. Accurate diagnosis involves checking system components, pressure gauges, and flow meters to identify discrepancies and restore optimal operation.

Maximum flow rate Infographic

libterm.com

libterm.com