A laminated shaft enhances mechanical performance by reducing weight while maintaining strength and rigidity. Its layered construction improves vibration damping and increases resistance to torsional stress. Explore the benefits and applications of laminated shafts to optimize Your engineering projects.

Table of Comparison

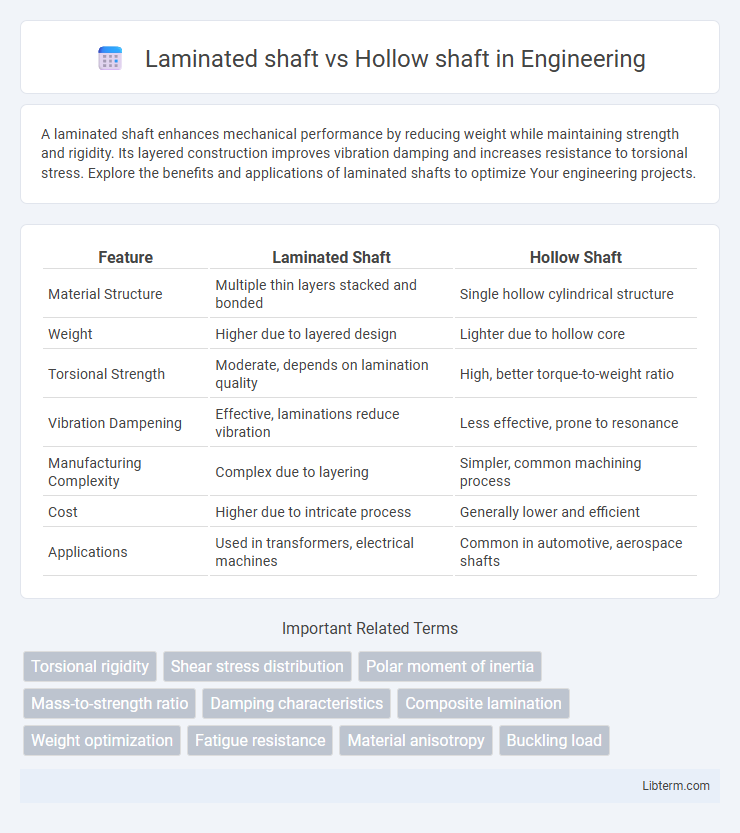

| Feature | Laminated Shaft | Hollow Shaft |

|---|---|---|

| Material Structure | Multiple thin layers stacked and bonded | Single hollow cylindrical structure |

| Weight | Higher due to layered design | Lighter due to hollow core |

| Torsional Strength | Moderate, depends on lamination quality | High, better torque-to-weight ratio |

| Vibration Dampening | Effective, laminations reduce vibration | Less effective, prone to resonance |

| Manufacturing Complexity | Complex due to layering | Simpler, common machining process |

| Cost | Higher due to intricate process | Generally lower and efficient |

| Applications | Used in transformers, electrical machines | Common in automotive, aerospace shafts |

Introduction to Shaft Types

Laminated shafts consist of multiple layers of metal or composite materials bonded together to enhance strength and reduce weight, making them ideal for applications requiring high torsional rigidity and vibration damping. Hollow shafts feature a cylindrical form with a hollow center, providing a balance between strength and reduced material usage, which lowers overall weight while maintaining structural integrity. Both laminated and hollow shafts are essential in mechanical systems where torque transmission, weight considerations, and performance optimization are critical.

What is a Laminated Shaft?

A laminated shaft consists of multiple thin layers of metal sheets stacked and bonded together to enhance magnetic properties and reduce eddy current losses, commonly used in electrical machines. This design improves efficiency by minimizing energy loss and heat generation compared to solid shafts. Laminated shafts are essential in motors and generators where electromagnetic performance and thermal management are critical.

What is a Hollow Shaft?

A hollow shaft is a cylindrical mechanical component with a hollow center, designed to reduce weight while maintaining structural strength and torque transmission capabilities. It offers improved torsional rigidity and efficiency compared to solid shafts, making it ideal for applications requiring lighter rotating parts and reduced inertia. Hollow shafts are commonly used in automotive, aerospace, and industrial machinery to enhance performance and energy savings.

Structural Composition: Laminated vs Hollow

Laminated shafts consist of multiple layers of metal sheets stacked and bonded together, enhancing flexibility and vibration damping in mechanical systems. Hollow shafts are solid cylinders with a central cavity, offering a high strength-to-weight ratio while reducing material usage and overall shaft weight. The structural composition of laminated shafts provides superior shock absorption compared to the rigid, lighter, and torsionally stronger hollow shafts favored in high-performance applications.

Weight and Strength Comparison

Laminated shafts typically offer higher strength-to-weight ratios due to layered construction, which enhances mechanical properties without significantly increasing weight. Hollow shafts reduce overall weight compared to solid laminated shafts but may sacrifice some tensile and torsional strength depending on material and wall thickness. Engineering applications often select laminated shafts when maximum strength is critical, while hollow shafts are preferred for lighter weight and moderate strength requirements.

Performance and Efficiency Differences

Laminated shafts offer enhanced magnetic performance and reduced eddy current losses due to their layered construction, resulting in higher efficiency in electric motors and transformers. Hollow shafts provide mechanical advantages such as lower weight and improved balance but may experience slightly reduced magnetic efficiency compared to laminated solid cores. The choice between laminated and hollow shafts depends on the trade-off between electromagnetic performance and mechanical design requirements.

Cost Analysis: Laminated vs Hollow Shaft

Laminated shafts typically offer cost advantages over hollow shafts due to lower material usage and simplified manufacturing processes, reducing initial production expenses. However, hollow shafts may provide better strength-to-weight ratios, potentially lowering long-term operational costs in applications where weight reduction is critical. Comprehensive cost analysis must consider not only upfront material and fabrication costs but also factors such as maintenance, durability, and performance efficiency for optimal selection.

Common Applications for Each Shaft Type

Laminated shafts are predominantly utilized in electrical machines such as transformers, motors, and generators, where reduced eddy current losses and improved magnetic performance are critical. Hollow shafts find common applications in heavy machinery, automotive drivetrains, and aerospace components due to their lightweight structure and high torque capacity. Both shaft types serve specialized roles based on mechanical and electromagnetic requirements in industrial, automotive, and energy sectors.

Durability and Maintenance Considerations

Laminated shafts offer enhanced durability due to their layered construction, which provides better resistance to fatigue and stress compared to hollow shafts. Hollow shafts, while lighter and easier to maintain because of their simplified structure, may experience reduced durability under high-torque applications. Maintenance considerations favor laminated shafts in heavy-duty environments for longevity, whereas hollow shafts require less frequent inspections in lighter-duty or rotational speed-critical systems.

Choosing the Right Shaft for Your Needs

Selecting the appropriate shaft depends on the application's strength, weight, and cost requirements. Laminated shafts offer enhanced magnetic properties and are ideal for electrical machinery requiring reduced eddy current losses. Hollow shafts provide a lightweight solution with excellent torsional strength, making them suitable for automotive and industrial uses where weight reduction and durability are critical.

Laminated shaft Infographic

libterm.com

libterm.com