Effective area contact techniques improve signal transmission and reduce resistance in electronic devices. Ensuring proper alignment and surface smoothness enhances connectivity and overall performance. Explore the rest of the article to discover how optimizing area contact can benefit your technology applications.

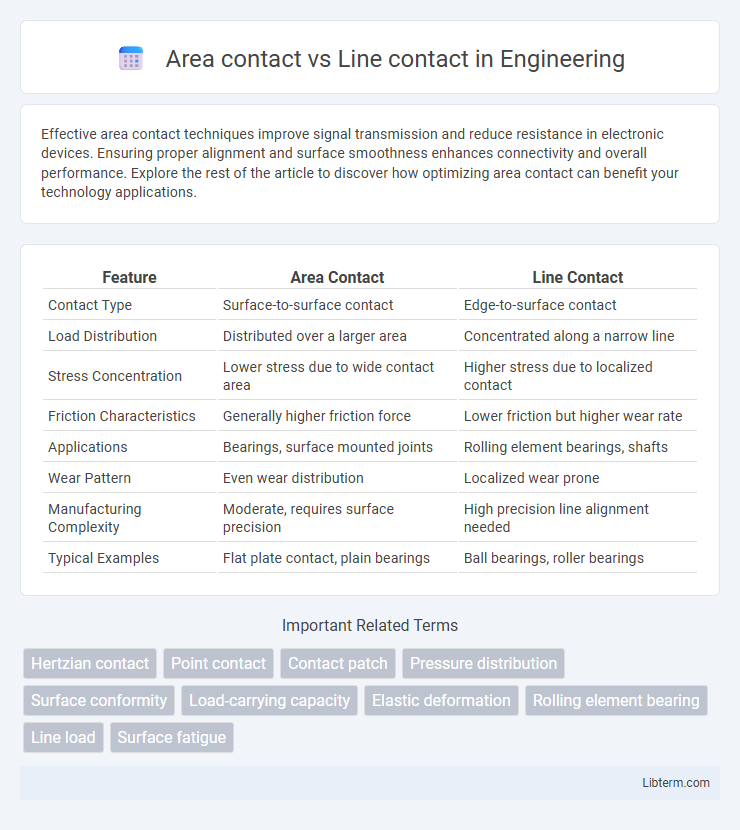

Table of Comparison

| Feature | Area Contact | Line Contact |

|---|---|---|

| Contact Type | Surface-to-surface contact | Edge-to-surface contact |

| Load Distribution | Distributed over a larger area | Concentrated along a narrow line |

| Stress Concentration | Lower stress due to wide contact area | Higher stress due to localized contact |

| Friction Characteristics | Generally higher friction force | Lower friction but higher wear rate |

| Applications | Bearings, surface mounted joints | Rolling element bearings, shafts |

| Wear Pattern | Even wear distribution | Localized wear prone |

| Manufacturing Complexity | Moderate, requires surface precision | High precision line alignment needed |

| Typical Examples | Flat plate contact, plain bearings | Ball bearings, roller bearings |

Introduction to Area Contact and Line Contact

Area contact involves the interaction of two surfaces over a finite region, providing increased load distribution and enhanced resistance to wear in mechanical systems. Line contact occurs when two surfaces meet along a single line, concentrating stress but allowing for greater flexibility in movements such as rolling and sliding. Understanding the distinction between area contact and line contact is crucial for optimizing design choices in bearings, gear teeth, and other contact mechanics applications.

Definitions: Area Contact vs Line Contact

Area contact refers to the interaction between two surfaces where a substantial portion of their faces touch, distributing force over a broad region and reducing pressure per unit area. Line contact occurs when two curved surfaces meet along a single line, concentrating the force along this narrow intersection and increasing the localized stress. Bearings and gear teeth often illustrate these contacts, with rolling element bearings typically exhibiting line contact and plain bearings demonstrating area contact.

Key Differences Between Area Contact and Line Contact

Area contact involves the interaction of surfaces over a broad region, resulting in higher load capacity and lower stress concentration, which is essential for applications requiring durability and stability. Line contact occurs along a narrow line between two surfaces, leading to higher contact stress but reduced friction, making it suitable for rolling element bearings and gears. Key differences include the distribution of contact forces, wear patterns, and suitability for different mechanical components under varying load conditions.

Principles of Area Contact

Area contact involves a surface-to-surface interaction where the load is distributed over a larger contact region, reducing stress concentration and enhancing durability. This principle relies on maximizing the contact area to improve load transfer, frictional stability, and wear resistance in mechanical joints or bearings. Unlike line contact, which concentrates stress along a narrow line, area contact ensures more uniform load distribution, minimizing material deformation and failure risk.

Principles of Line Contact

Line contact occurs when two curved surfaces touch along a line rather than a single point, allowing for greater load distribution and reduced stress compared to area contact. This principle is essential in applications like roller bearings and cylindrical gears, where the contact line enhances durability and minimizes wear. Efficient line contact improves frictional performance and extends component lifespan by maintaining consistent pressure along the contact path.

Applications in Engineering and Design

Area contact provides uniform load distribution, making it ideal for applications requiring high stability and reduced stress concentrations, such as in heavy machinery bearings and gear teeth. Line contact, offering reduced friction and improved alignment, is preferred in rolling element bearings, cam-follower mechanisms, and precision instrument design. Engineering applications balance these contact types based on load capacity, wear resistance, and motion accuracy requirements.

Advantages and Disadvantages of Each Contact Type

Area contact provides superior load distribution and stability by spreading contact forces over a larger surface, reducing stress concentrations and wear. This type of contact is advantageous for applications requiring high durability and resistance to deformation, but it can result in increased friction and energy loss due to larger contact areas. Line contact, conversely, offers lower friction and more precise alignment due to the reduced contact area, making it ideal for high-speed and low-load conditions, though it may suffer from higher stress concentrations and faster wear in heavy load scenarios.

Impact on Load Distribution

Area contact distributes load over a larger surface area, resulting in lower contact stress and enhanced durability in mechanical systems such as gears and bearings. Line contact concentrates the load along a narrow line, increasing stress intensity and potential for localized wear or deformation, commonly seen in roller bearings or cylindrical gears. Optimizing load distribution through appropriate contact type selection improves performance, reduces material fatigue, and extends component lifespan.

Real-World Examples and Case Studies

Area contact, such as in ball bearings and seal faces, distributes load over a larger surface, reducing stress and wear in automotive wheel hubs and industrial gearboxes. Line contact, found in cylindrical roller bearings and cam followers, concentrates load along a narrow path, enabling higher load capacities for heavy machinery like construction equipment and wind turbine shafts. Case studies reveal that switching from line to area contact in electric vehicle drivetrain components lowers maintenance costs and enhances durability by minimizing localized stress concentrations.

Conclusion: Choosing Between Area Contact and Line Contact

Selecting between area contact and line contact hinges on the specific application requirements such as load distribution, friction, and wear characteristics. Area contact offers superior load capacity and stability due to a larger contact surface, making it ideal for high-load and low-speed applications. Line contact provides reduced friction and precise alignment suitable for high-speed operations with lower load demands, emphasizing the importance of matching contact type to operational conditions.

Area contact Infographic

libterm.com

libterm.com