Maximum load refers to the highest amount of weight or force a structure, equipment, or system can safely support without failure or damage. Understanding your maximum load capacity is critical for ensuring safety, efficiency, and longevity in various applications, from construction to machinery operation. Explore the rest of this article to learn how to accurately determine and apply maximum load limits in your specific context.

Table of Comparison

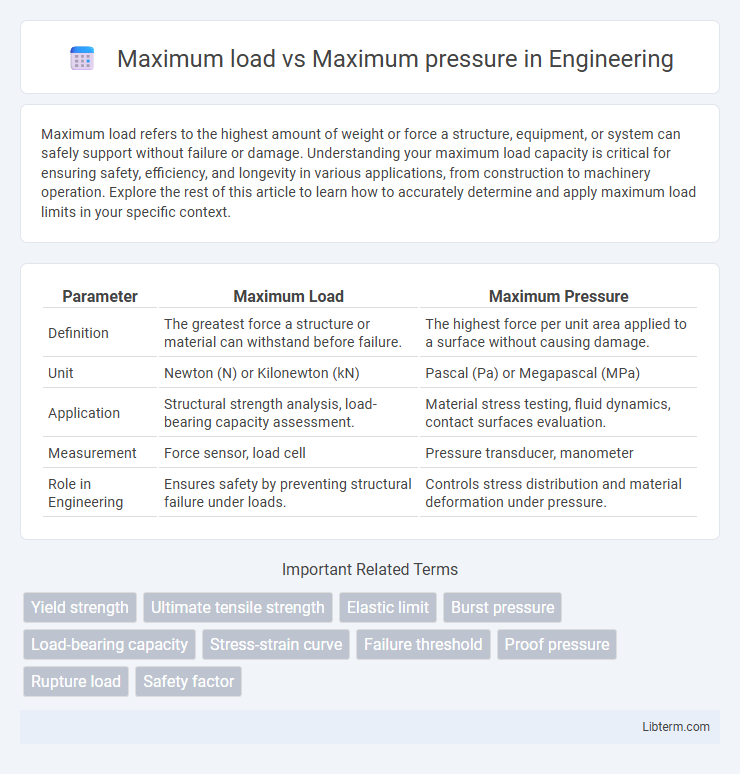

| Parameter | Maximum Load | Maximum Pressure |

|---|---|---|

| Definition | The greatest force a structure or material can withstand before failure. | The highest force per unit area applied to a surface without causing damage. |

| Unit | Newton (N) or Kilonewton (kN) | Pascal (Pa) or Megapascal (MPa) |

| Application | Structural strength analysis, load-bearing capacity assessment. | Material stress testing, fluid dynamics, contact surfaces evaluation. |

| Measurement | Force sensor, load cell | Pressure transducer, manometer |

| Role in Engineering | Ensures safety by preventing structural failure under loads. | Controls stress distribution and material deformation under pressure. |

Understanding Maximum Load and Maximum Pressure

Maximum load refers to the greatest amount of force or weight a material or structure can withstand before failure, while maximum pressure denotes the highest force exerted per unit area within a system. Understanding maximum load is crucial for designing safe structures by ensuring they can support expected weights without collapsing. Maximum pressure assessment is essential in applications involving fluids or gases, where it determines the limits before causing deformation or rupture in containers or pipelines.

Key Differences Between Maximum Load and Pressure

Maximum load refers to the greatest force or weight a structure or material can bear without failing, measured in units like Newtons or pounds. Maximum pressure, by contrast, denotes the highest force applied per unit area, expressed in Pascals or psi, emphasizing distribution rather than total force. Key differences lie in their dimensional focus: load concerns total force capacity, while pressure targets force intensity over a specific area.

The Science Behind Load-Bearing Capacity

Maximum load represents the total weight or force a structure or material can support before failure, measured in units such as Newtons or kilograms. Maximum pressure refers to the highest force applied per unit area, expressed in Pascals (Pa), which directly influences stress distribution within the material. Understanding the science behind load-bearing capacity involves analyzing how maximum load and pressure interact with material properties like tensile strength, elasticity, and structural geometry to prevent deformation or collapse.

Factors Influencing Maximum Pressure

Maximum pressure depends on factors such as material strength, contact surface area, and load distribution, which determine how force is applied over a specific area. Maximum load refers to the highest force a structure or material can withstand before failure, but maximum pressure specifically relates to the intensity of force per unit area. Variations in temperature, surface roughness, and presence of lubricants also influence maximum pressure by altering frictional forces and stress concentrations.

Importance of Material Strength in Load and Pressure

Material strength critically influences maximum load capacity by determining the ability of a structure to withstand forces without failure. Maximum pressure depends on the material's tensile and compressive strength, impacting how much stress can be applied before deformation or rupture occurs. Understanding the relationship between material properties such as yield strength, toughness, and elasticity is essential to optimize load-bearing and pressure-resisting capabilities in engineering applications.

Applications: When to Consider Load vs Pressure

Maximum load is critical in structural engineering for applications like bridge design and building construction, where the total weight or force the structure must support is paramount. In contrast, maximum pressure is crucial in fluid systems, hydraulic machinery, and pressure vessel design, where the force exerted per unit area determines safety and performance. Selecting between load and pressure depends on whether the application involves distributed forces across surfaces or concentrated stresses within materials or fluids.

Measuring Maximum Load and Pressure: Methods and Tools

Measuring maximum load involves using strain gauges, load cells, or dynamometers to quantify the highest force a material or structure can withstand before failure, providing precise data on tensile, compressive, or shear forces. Maximum pressure measurement often employs pressure transducers, manometers, or piezoelectric sensors to capture the peak internal or applied pressure within fluids or gases, crucial for safety and performance assessments. Advanced methods combine digital data acquisition systems and real-time monitoring to ensure accurate and reliable determination of both maximum load and pressure in engineering applications.

Common Mistakes in Interpreting Load and Pressure Ratings

Misinterpreting maximum load as maximum pressure often leads to critical design errors, as load refers to force applied while pressure denotes force per unit area. Engineers frequently confuse these ratings by overlooking the material surface area, causing overestimation of structural capacity and potential failure. Accurate assessment requires understanding that maximum load is an absolute value, whereas maximum pressure depends on contact area and distribution.

Industry Standards for Load and Pressure Limits

Industry standards for maximum load and maximum pressure establish critical safety thresholds to ensure structural integrity and operational efficiency in engineering applications. Maximum load refers to the greatest force or weight a material or structure can withstand without failure, commonly defined by standards such as ASTM, ISO, and ASME guidelines. Maximum pressure pertains to the highest internal or external pressure a system, like a pressure vessel or pipeline, can safely endure, often regulated by codes such as ASME BPVC and API standards to prevent catastrophic failures.

Optimizing Design for Maximum Load and Pressure Safety

Optimizing design for maximum load and pressure safety requires precise calculation of structural limits and material strength to prevent failure under extreme conditions. Finite element analysis and real-time monitoring systems enhance accuracy in assessing maximum load capacity and pressure thresholds, ensuring components withstand operational stresses. Incorporating factors like safety margins, fatigue resistance, and pressure distribution results in resilient designs that maximize performance while minimizing risk.

Maximum load Infographic

libterm.com

libterm.com