Whirling speed refers to the critical rotational speed at which a rotating shaft or component begins to experience lateral vibrations, potentially leading to mechanical failure. Understanding and managing whirling speed is essential for ensuring the stability and longevity of rotating machinery such as turbines, motors, and drive shafts. Dive deeper into this article to learn how whirling speed affects your equipment and ways to control it effectively.

Table of Comparison

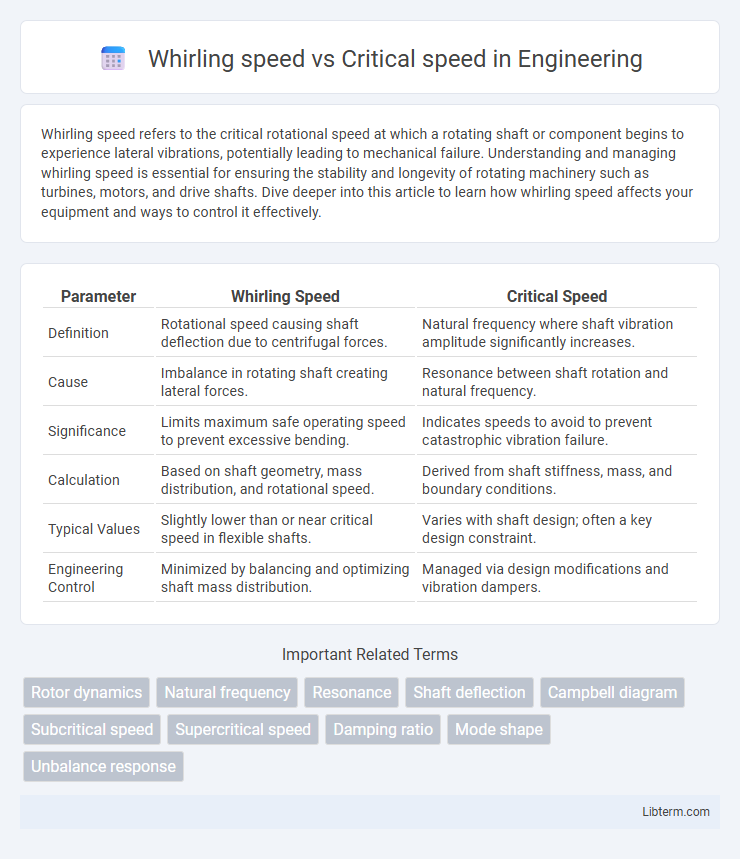

| Parameter | Whirling Speed | Critical Speed |

|---|---|---|

| Definition | Rotational speed causing shaft deflection due to centrifugal forces. | Natural frequency where shaft vibration amplitude significantly increases. |

| Cause | Imbalance in rotating shaft creating lateral forces. | Resonance between shaft rotation and natural frequency. |

| Significance | Limits maximum safe operating speed to prevent excessive bending. | Indicates speeds to avoid to prevent catastrophic vibration failure. |

| Calculation | Based on shaft geometry, mass distribution, and rotational speed. | Derived from shaft stiffness, mass, and boundary conditions. |

| Typical Values | Slightly lower than or near critical speed in flexible shafts. | Varies with shaft design; often a key design constraint. |

| Engineering Control | Minimized by balancing and optimizing shaft mass distribution. | Managed via design modifications and vibration dampers. |

Introduction to Whirling Speed and Critical Speed

Whirling speed refers to the rotational speed at which a shaft or rotor begins to exhibit lateral vibrations due to bending, potentially causing instability in machinery. Critical speed is the specific rotational speed at which the natural frequency of the shaft matches the rotational frequency, leading to resonance and significant amplitude increases in vibration. Understanding the relationship between whirling speed and critical speed is essential for designing rotating equipment to avoid operational failures and ensure structural integrity.

Defining Whirling Speed: Concepts and Importance

Whirling speed refers to the rotational speed at which a shaft or rotor begins to experience lateral vibrations due to bending flexibility, potentially leading to dangerous resonance conditions. It is critical to distinguish whirling speed from critical speed, as the former denotes the onset of significant deflection while the latter represents the exact speed causing maximum amplitude oscillations and potential system failure. Understanding whirling speed is essential for designing rotating machinery to avoid operational instabilities and ensure mechanical integrity.

Understanding Critical Speed in Rotating Machinery

Critical speed is the rotational velocity at which a rotating shaft or rotor experiences resonance, causing excessive vibrations and potential structural failure. Whirling speed refers to the lateral oscillation frequency of the shaft before reaching the critical speed, often influenced by shaft stiffness and boundary conditions. Understanding critical speed is essential for designing rotating machinery to avoid resonance, ensuring operational stability and longevity.

Key Differences Between Whirling Speed and Critical Speed

Whirling speed refers to the specific rotational velocity at which a shaft or rotor exhibits lateral vibrations due to an imbalance, while critical speed is the rotational speed where the natural frequency of the system matches the excitation frequency, causing resonance. Key differences include that whirling speed is primarily influenced by shaft stiffness and mass distribution, whereas critical speed depends on system damping and boundary conditions. Understanding these distinctions is crucial for preventing excessive vibrations in rotating machinery, ensuring operational stability and longevity.

Factors Affecting Whirling Speed

Whirling speed is influenced by factors such as shaft stiffness, mass distribution, and damping characteristics, which determine the shaft's ability to resist lateral deflections under rotation. Changes in material properties, geometric dimensions, and rotational speed also affect the whirling behavior by altering the natural frequencies of the system. Critical speed marks the transition point where the whirling frequency matches the shaft's natural frequency, leading to resonance and potential mechanical failure.

Parameters Influencing Critical Speed

Critical speed is primarily influenced by parameters such as shaft stiffness, mass distribution, and support conditions, which determine the natural frequency at which resonance occurs. Whirling speed, the rotational speed causing lateral vibration, approaches critical speed when the rotor's angular velocity aligns with its natural frequency. Optimizing these parameters, including material properties and geometric dimensions, is essential to avoid operating near critical speed and prevent excessive vibrations or mechanical failure.

Practical Implications in Mechanical Design

Whirling speed refers to the rotational speed at which a shaft or rotor begins to exhibit significant lateral vibrations, while critical speed is the natural frequency at which resonance occurs, causing severe amplitude oscillations. In mechanical design, accurately predicting and avoiding operation near the critical speed is crucial to prevent catastrophic failure and ensure structural integrity. Engineers implement dynamic balancing, stiffness enhancement, and damping mechanisms to mitigate whirling effects and maintain safe operational limits.

Dangers of Operating Near Whirling or Critical Speed

Operating near whirling or critical speed poses severe risks such as excessive vibrations that can lead to mechanical failure, bearing damage, and shaft fatigue. These conditions amplify dynamic forces, causing resonance that compromises alignment and structural integrity. Ignoring these dangers often results in costly downtime and catastrophic equipment breakdown in rotating machinery.

Methods for Calculating Whirling and Critical Speeds

Whirling speed is calculated using methods such as Rayleigh's energy method and Dunkerley's formula, which estimate natural frequencies based on shaft geometry and material properties. Critical speed is determined through analytical approaches including the Euler-Bernoulli beam theory and finite element analysis (FEA) to identify eigenvalues corresponding to resonance conditions. Both methods require accurate input parameters like shaft stiffness, mass distribution, and boundary conditions to ensure precise predictions of rotor dynamic behavior.

Preventive Measures and Best Practices

Whirling speed approaches can induce resonance in rotating machinery when it nears critical speed, causing excessive vibrations and potential damage. Preventive measures include precise balancing of rotating components, frequent monitoring through vibration analysis, and maintaining proper alignment to avoid operating near critical speeds. Best practices also involve using dampers, selecting appropriate shaft materials, and implementing controlled acceleration to minimize the risk of surpassing critical speed thresholds.

Whirling speed Infographic

libterm.com

libterm.com