A sliding pair is a type of kinematic pair where two surfaces slide relative to each other, allowing motion predominantly in one direction while restricting other movements. This mechanical contact is crucial in machines like pistons, linear guides, and rail systems, ensuring smooth and controlled linear motion. Explore the rest of the article to understand how sliding pairs contribute to mechanical design and performance in various applications.

Table of Comparison

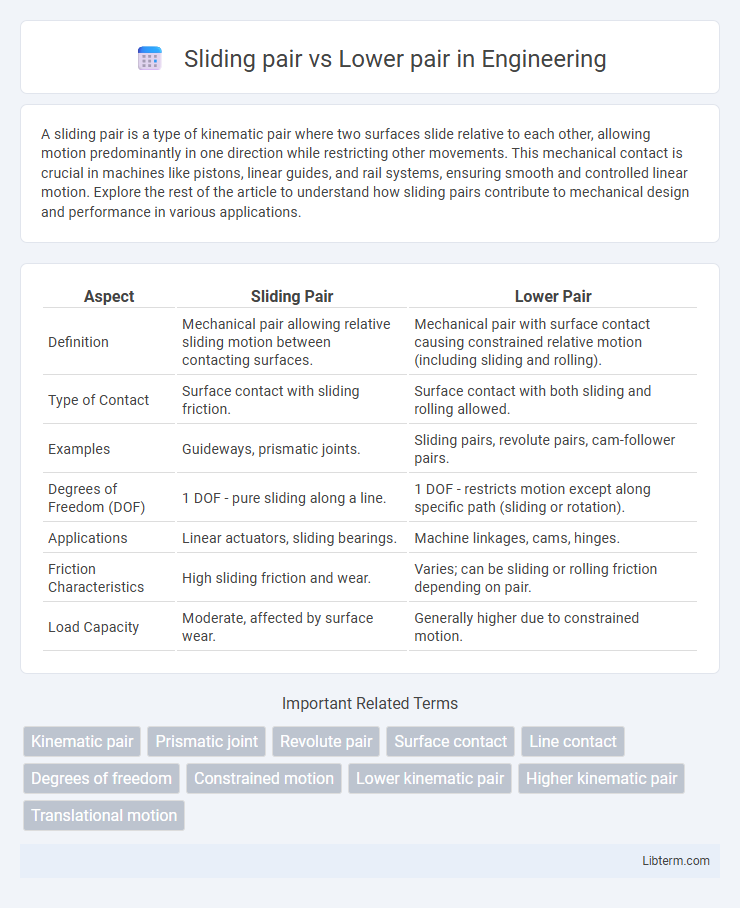

| Aspect | Sliding Pair | Lower Pair |

|---|---|---|

| Definition | Mechanical pair allowing relative sliding motion between contacting surfaces. | Mechanical pair with surface contact causing constrained relative motion (including sliding and rolling). |

| Type of Contact | Surface contact with sliding friction. | Surface contact with both sliding and rolling allowed. |

| Examples | Guideways, prismatic joints. | Sliding pairs, revolute pairs, cam-follower pairs. |

| Degrees of Freedom (DOF) | 1 DOF - pure sliding along a line. | 1 DOF - restricts motion except along specific path (sliding or rotation). |

| Applications | Linear actuators, sliding bearings. | Machine linkages, cams, hinges. |

| Friction Characteristics | High sliding friction and wear. | Varies; can be sliding or rolling friction depending on pair. |

| Load Capacity | Moderate, affected by surface wear. | Generally higher due to constrained motion. |

Introduction to Kinematic Pairs

Sliding pairs are kinematic pairs characterized by the relative motion of one element sliding over another, typically producing linear or planar movement, whereas lower pairs involve surface contact with higher kinematic constraints like revolute or prismatic joints. Lower pairs allow relative motion through a pair of carefully fitted surfaces, enabling precise mechanical linkages essential in mechanisms such as crankshafts or hinge joints. Understanding the distinction between sliding pairs and lower pairs is fundamental in kinematics to analyze and design mechanical systems with controlled degrees of freedom.

Definition of Sliding Pair

A sliding pair is a type of kinematic pair where two elements have relative motion constrained to pure sliding along a surface, typically characterized by one degree of freedom. Unlike a lower pair, which allows surface contact with various motions such as rolling or spinning, a sliding pair specifically involves continuous sliding with no rotation or rolling allowed. This fundamental distinction in motion constraints defines the classification and application of sliding pairs in mechanisms and machinery.

Definition of Lower Pair

Lower pairs are kinematic pairs characterized by surface contact that enables constrained motion between two bodies, such as sliding, rolling, or turning. Unlike higher pairs, which involve point or line contact, lower pairs maintain a higher degree of constraint and stability through full surface engagement. Examples of lower pairs include revolute (hinge) pairs, prismatic (slider) pairs, and cylindrical pairs, all fundamental in mechanical linkages and machinery design.

Key Characteristics of Sliding Pairs

Sliding pairs are mechanical linkages where two components slide relative to each other, characterized by linear or rectilinear motion along a common surface. These pairs feature continuous surface contact, enabling smooth, controlled movement with minimal play, typically found in applications like piston-cylinder assemblies and linear guides. Unlike lower pairs, which may include rotary motion, sliding pairs specifically facilitate translational motion with high precision and reduced friction.

Key Characteristics of Lower Pairs

Lower pairs in kinematics are characterized by surface contact, allowing relative sliding or rolling motion, unlike sliding pairs that primarily feature sliding contact. Key characteristics of lower pairs include their ability to transmit motion and force with higher precision due to controlled surface engagement, which leads to reduced wear and increased stability in mechanical systems. These pairs are fundamental in mechanisms such as gears and cam systems, where precise angular or linear movement is essential.

Differences Between Sliding Pair and Lower Pair

Sliding pairs involve relative motion characterized by linear sliding between surfaces, whereas lower pairs encompass all types of pairs with surface contact, including sliding, rolling, and turning motions. The primary difference lies in motion type: sliding pairs are a subset of lower pairs with purely sliding contact, while lower pairs can include more complex kinematic interactions. Surface contact nature in sliding pairs results in higher friction compared to some lower pairs that may involve rolling or turning with reduced friction.

Examples of Sliding Pair Mechanisms

Sliding pair mechanisms include examples such as the piston and cylinder in internal combustion engines, the dovetail joint in machine tools, and the sliding door rail systems. These mechanisms involve two components with surface contact sliding relative to each other, enabling smooth linear or rotary motion. In contrast, lower pairs may also include turning pairs with rolling contact, but sliding pairs specifically emphasize direct sliding friction between mating surfaces.

Examples of Lower Pair Mechanisms

Lower pairs are mechanical joints characterized by surface contact and constrained relative motion, commonly found in mechanisms such as revolute pairs (pin joints) in four-bar linkages or prismatic pairs (sliding joints) in hydraulic cylinders. Examples of lower pair mechanisms include the crankshaft and connecting rod assembly in internal combustion engines, which utilizes revolute pairs for rotational motion transfer. Sliding pairs, a subtype of lower pairs, specifically involve sliding contact and are pivotal in applications like linear sliders and piston-cylinder arrangements.

Applications in Mechanical Engineering

Sliding pairs are essential in applications requiring linear motion with minimal friction, such as in hydraulic cylinders and telescopic slides, enabling smooth and controlled movement. Lower pairs, characterized by surface contact between components, are widely used in mechanisms like gears, cams, and crankshafts, facilitating precise rotational or oscillatory motion. Mechanical engineering leverages sliding pairs for guiding and supporting linear movements, while lower pairs excel in power transmission and converting motion types in complex machinery.

Summary and Comparative Table

Sliding pairs involve two surfaces moving linearly relative to each other, characterized by high friction and wear, commonly found in mechanisms like piston-cylinder assemblies. Lower pairs encompass relative motion with surface contact, including sliding, turning, or rolling, and are categorized into sliding pairs, turning pairs, and rolling pairs based on motion type and contact area. Comparative analysis shows sliding pairs have line contact with sliding motion causing friction, while other lower pairs may have point or area contact with rotary or rolling movements resulting in varying frictional characteristics. | Feature | Sliding Pair | Other Lower Pairs | |---------------------|-------------------------------------|----------------------------------| | Motion Type | Linear sliding | Rotary (turning), rolling, or sliding | | Contact Area | Line contact | Point or surface contact | | Friction | High, due to sliding contact | Lower in rolling pairs, moderate in turning pairs | | Wear Rate | Relatively high | Lower in rolling pairs, moderate in turning pairs | | Examples | Piston-cylinder, guideways | Hinges (turning), ball bearings (rolling) |

Sliding pair Infographic

libterm.com

libterm.com