Vibration mitigation techniques are essential for reducing unwanted oscillations in machinery, structures, and vehicles, thereby enhancing performance and longevity. Effective strategies include isolating sources of vibration, using damping materials, and implementing active control systems tailored to specific applications. Explore the rest of this article to discover how these methods can optimize your equipment's stability and efficiency.

Table of Comparison

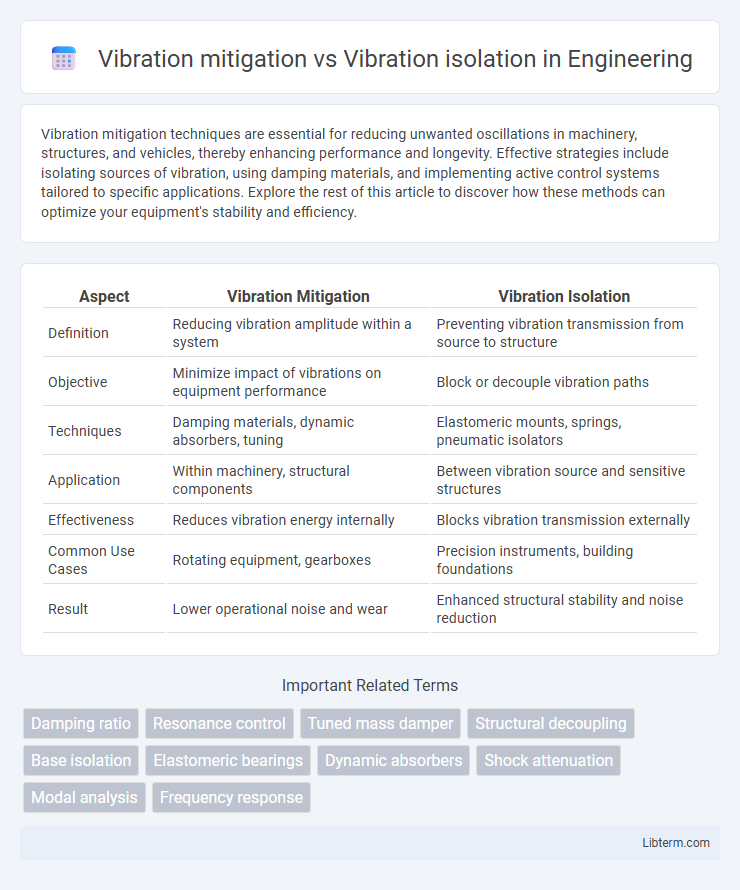

| Aspect | Vibration Mitigation | Vibration Isolation |

|---|---|---|

| Definition | Reducing vibration amplitude within a system | Preventing vibration transmission from source to structure |

| Objective | Minimize impact of vibrations on equipment performance | Block or decouple vibration paths |

| Techniques | Damping materials, dynamic absorbers, tuning | Elastomeric mounts, springs, pneumatic isolators |

| Application | Within machinery, structural components | Between vibration source and sensitive structures |

| Effectiveness | Reduces vibration energy internally | Blocks vibration transmission externally |

| Common Use Cases | Rotating equipment, gearboxes | Precision instruments, building foundations |

| Result | Lower operational noise and wear | Enhanced structural stability and noise reduction |

Introduction to Vibration Control

Vibration mitigation involves reducing the amplitude and impact of vibrations through methods like damping, energy absorption, and structural modifications. Vibration isolation aims to prevent vibration transmission by introducing barriers such as isolators or mounts that decouple the source from sensitive components. Both approaches form critical strategies in vibration control, optimizing system performance and longevity by addressing vibration at different stages.

Defining Vibration Mitigation

Vibration mitigation refers to the process of reducing the amplitude and harmful effects of vibrations in mechanical systems through methods such as damping, absorption, or structural modification. Unlike vibration isolation, which aims to prevent vibration transmission by separating the source from sensitive components using mounts or isolators, vibration mitigation focuses on controlling vibrations within the system itself. Effective vibration mitigation improves equipment life, enhances operational stability, and reduces noise by dissipating or redirecting vibrational energy.

Understanding Vibration Isolation

Vibration isolation involves installing devices or systems designed to prevent the transmission of vibration from a source to surrounding structures or sensitive equipment, reducing the impact of vibrations on performance and longevity. Effective vibration isolation often utilizes materials like elastomers, springs, or pneumatic mounts that absorb and dissipate vibrational energy before it reaches critical components. Understanding vibration isolation is essential in engineering applications, such as machinery foundations or precision instruments, where controlling vibrational transfer improves reliability and operational accuracy.

Key Differences: Mitigation vs Isolation

Vibration mitigation involves reducing the amplitude of vibrations through damping materials or structural modifications, effectively lessening the impact on machinery or structures without completely preventing vibration transmission. Vibration isolation, on the other hand, aims to completely block or significantly reduce the transmission of vibration from a source to surrounding environments using isolators like springs or rubber mounts. The key difference lies in mitigation decreasing vibration effects, whereas isolation focuses on preventing vibration transfer altogether.

Applications of Vibration Mitigation

Vibration mitigation involves reducing vibration levels within structures or machinery through techniques such as damping, tuning, and material selection, enhancing equipment longevity and operational precision. It is widely applied in aerospace for improving aircraft stability, in automotive industries for reducing noise and wear, and in buildings to protect sensitive equipment from seismic or operational vibrations. Unlike vibration isolation, which physically separates the source and receiver to prevent transmission, mitigation focuses on controlling and minimizing vibrations directly at the source or along the path.

Applications of Vibration Isolation

Vibration isolation is extensively applied in precision manufacturing, where it protects sensitive equipment like CNC machines and optical instruments from external vibrations, ensuring accuracy and quality. It is critical in building construction to minimize the transmission of ground-borne vibrations from nearby traffic or machinery, enhancing structural integrity and occupant comfort. In the automotive industry, vibration isolation systems improve ride quality and reduce noise by decoupling engine and chassis vibrations.

Advantages and Limitations of Each Approach

Vibration mitigation reduces the amplitude of vibrations through damping materials and structural modifications, offering cost-effective solutions for moderate vibration levels but often struggling with high-frequency vibrations. Vibration isolation physically separates equipment from vibration sources using mounts or isolators, providing superior protection for sensitive instruments but requiring more space and higher initial investment. Each approach balances effectiveness with practical constraints, making the choice dependent on the specific vibration characteristics and application requirements.

When to Use Mitigation vs Isolation

Vibration mitigation is ideal when the goal is to reduce the amplitude of vibrations within a system already experiencing dynamic forces, often through damping materials or tuned mass dampers. Vibration isolation is preferred when the objective is to prevent the transmission of vibrations from a source to sensitive equipment or structures, typically using isolators such as springs, rubber mounts, or air suspensions. Choose mitigation for controlling vibration effects internally, while isolation is best for separating and protecting components from external vibration sources.

Emerging Technologies in Vibration Control

Emerging technologies in vibration control are shifting focus from traditional vibration isolation to advanced vibration mitigation techniques that actively reduce unwanted motion through smart materials and real-time adaptive systems. Innovations such as piezoelectric sensors, magnetorheological dampers, and AI-driven feedback loops enhance the precision and efficiency of vibration mitigation by dynamically responding to changing environmental conditions. These advancements outperform conventional passive isolation methods, offering improved durability and performance in industries ranging from aerospace to civil engineering.

Conclusion: Choosing the Right Vibration Solution

Selecting the appropriate vibration solution depends on the specific requirements of the application, where vibration mitigation reduces the amplitude of vibrations within a system, while vibration isolation prevents the transmission of vibrations to surrounding structures. Industries such as manufacturing, aerospace, and automotive benefit from tailored approaches based on factors like frequency range, load capacity, and environmental conditions. Effective vibration control maximizes equipment lifespan, improves performance, and enhances safety by addressing either source reduction or isolation techniques.

Vibration mitigation Infographic

libterm.com

libterm.com