SCADA systems enable real-time monitoring and control of industrial processes, improving operational efficiency and reducing downtime. These systems integrate hardware and software components to collect data from sensors and equipment, providing vital insights for timely decision-making. Explore the rest of the article to understand how SCADA technology can enhance your industrial operations.

Table of Comparison

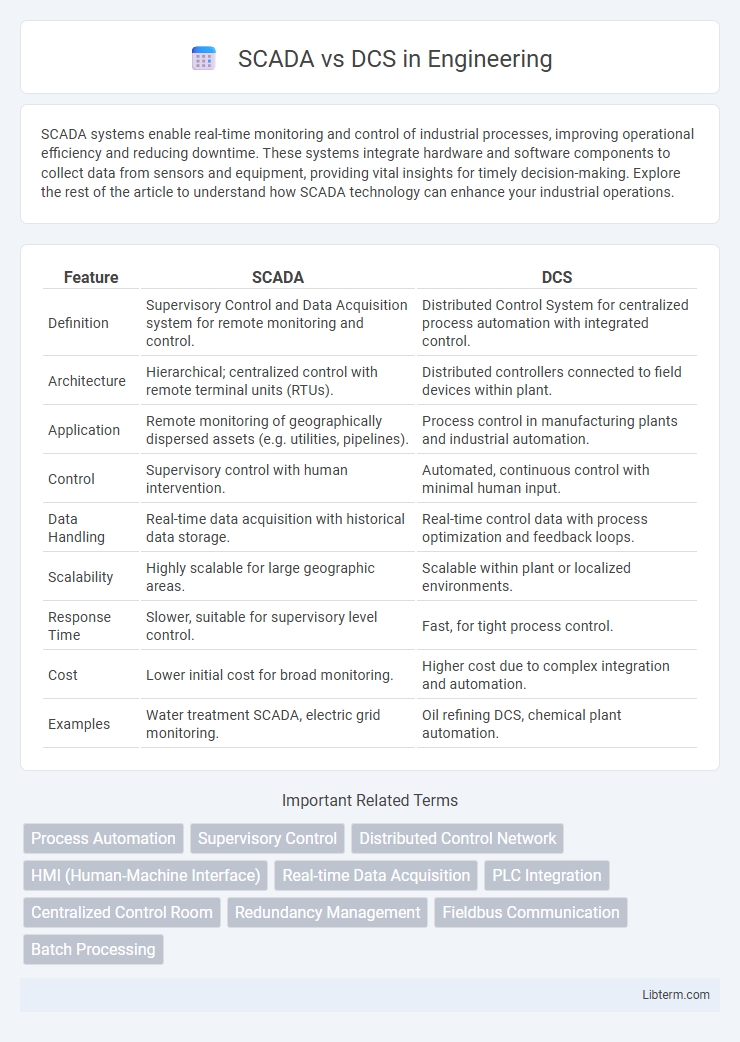

| Feature | SCADA | DCS |

|---|---|---|

| Definition | Supervisory Control and Data Acquisition system for remote monitoring and control. | Distributed Control System for centralized process automation with integrated control. |

| Architecture | Hierarchical; centralized control with remote terminal units (RTUs). | Distributed controllers connected to field devices within plant. |

| Application | Remote monitoring of geographically dispersed assets (e.g. utilities, pipelines). | Process control in manufacturing plants and industrial automation. |

| Control | Supervisory control with human intervention. | Automated, continuous control with minimal human input. |

| Data Handling | Real-time data acquisition with historical data storage. | Real-time control data with process optimization and feedback loops. |

| Scalability | Highly scalable for large geographic areas. | Scalable within plant or localized environments. |

| Response Time | Slower, suitable for supervisory level control. | Fast, for tight process control. |

| Cost | Lower initial cost for broad monitoring. | Higher cost due to complex integration and automation. |

| Examples | Water treatment SCADA, electric grid monitoring. | Oil refining DCS, chemical plant automation. |

Introduction to SCADA and DCS

SCADA (Supervisory Control and Data Acquisition) systems are designed for real-time monitoring and control of geographically dispersed assets, typically used in utilities like water treatment and power grids. DCS (Distributed Control Systems) focus on centralized control within a single facility, offering continuous process automation in industries such as chemical plants and refineries. Both systems use sensors, controllers, and communication networks, but SCADA emphasizes wide-area data acquisition while DCS concentrates on precise process control within localized environments.

Core Definitions and Key Concepts

SCADA (Supervisory Control and Data Acquisition) systems are designed for remote monitoring and control of distributed assets across large geographic areas, emphasizing data acquisition and centralized control. DCS (Distributed Control System) focuses on process automation within localized industrial plants, offering direct control of complex processes through a network of interconnected controllers. SCADA prioritizes real-time data collection and system visibility, while DCS ensures precise process regulation and reliability in continuous production environments.

Architecture Differences: SCADA vs DCS

SCADA (Supervisory Control and Data Acquisition) systems feature a distributed architecture with centralized control, enabling remote monitoring and control across widespread locations through RTUs and PLCs. DCS (Distributed Control Systems) employ a hierarchical, process-centric architecture where control functions are distributed across multiple controllers closely integrated with field devices for real-time automation. The architecture of SCADA emphasizes long-distance communication and data acquisition, while DCS focuses on localized control loops and process coordination within a unified control network.

Typical Applications in Industry

SCADA systems are typically used in large-scale industrial operations such as water treatment plants, oil and gas pipelines, and electrical power distribution networks, where real-time data collection and remote monitoring are essential. DCS is predominantly applied in process industries like chemical plants, refineries, and manufacturing facilities, providing integrated control over complex processes with multiple feedback loops for continuous production. Both systems enhance operational efficiency, but SCADA excels in wide-area monitoring while DCS delivers precise process automation.

Communication Protocols Compared

SCADA systems predominantly use communication protocols such as Modbus, DNP3, and IEC 60870-5-104 to enable long-distance data transmission and control across wide geographical areas. DCS relies on protocols like PROFIBUS, Foundation Fieldbus, and HART, which optimize real-time, high-speed data exchange within localized industrial environments. The choice of protocol impacts system interoperability, latency, and network topology, with SCADA protocols favoring flexibility and remote monitoring, while DCS protocols prioritize deterministic control and device-level integration.

Scalability and Flexibility Factors

SCADA systems offer high scalability, allowing easy integration of multiple remote sites with centralized monitoring, making them ideal for geographically dispersed operations. DCS architectures provide superior flexibility through modular design, supporting complex process controls and adaptive system expansions within localized environments. Scalability in SCADA is driven by networked communication protocols, whereas DCS flexibility excels in real-time process control customization and seamless addition of control loops.

Operator Interface and Control Capabilities

SCADA systems offer centralized operator interfaces designed for monitoring and controlling geographically dispersed assets with real-time data visualization and alarm management, enabling remote supervision. DCS provides integrated operator interfaces tightly coupled with process control loops, delivering precise, high-speed control and automation suited for continuous or batch process industries. The control capabilities of SCADA emphasize supervisory control and data acquisition, while DCS focuses on direct, deterministic control with advanced process control algorithms and redundant architecture ensuring system reliability.

Security Considerations in SCADA and DCS

SCADA systems often possess vulnerabilities due to their legacy infrastructure and widespread network exposure, making them prime targets for cyberattacks such as malware infiltration and unauthorized remote access. In contrast, Distributed Control Systems (DCS) benefit from more robust security architectures, including segmented networks and advanced encryption protocols, enhancing protection against industrial espionage and operational disruptions. Effective security strategies for both systems emphasize real-time monitoring, intrusion detection systems (IDS), and strict access controls to safeguard critical industrial processes.

Cost Implications and Implementation Challenges

SCADA systems generally have lower initial costs due to their simpler architecture and use of existing communication networks, making them suitable for geographically dispersed operations. DCS solutions incur higher upfront investment for integrated control hardware and software but offer advanced process control and reliability in centralized plant environments. Implementation challenges for SCADA include ensuring secure remote access and network reliability, while DCS requires complex engineering, rigorous testing, and higher maintenance expertise to manage sophisticated control loops and redundancy.

Choosing Between SCADA and DCS: Decision Factors

Choosing between SCADA and DCS depends on the scale and complexity of the industrial process, where SCADA systems excel in remote monitoring and control across dispersed locations, and DCS offers integrated automation with enhanced reliability for centralized, complex processes. Key decision factors include system architecture, real-time control requirements, and the need for scalability, with DCS favored for continuous process industries and SCADA for infrastructure and facility management. Cost considerations, ease of customization, and cybersecurity capabilities also influence the optimal selection for operational efficiency and risk management.

SCADA Infographic

libterm.com

libterm.com