Welding is a critical process in manufacturing and construction that joins materials, usually metals or thermoplastics, by applying heat or pressure to create a strong bond. Mastery of welding techniques ensures the durability and safety of structures, machinery, and vehicles. Discover essential welding methods, safety tips, and best practices to enhance your skills by reading the rest of this article.

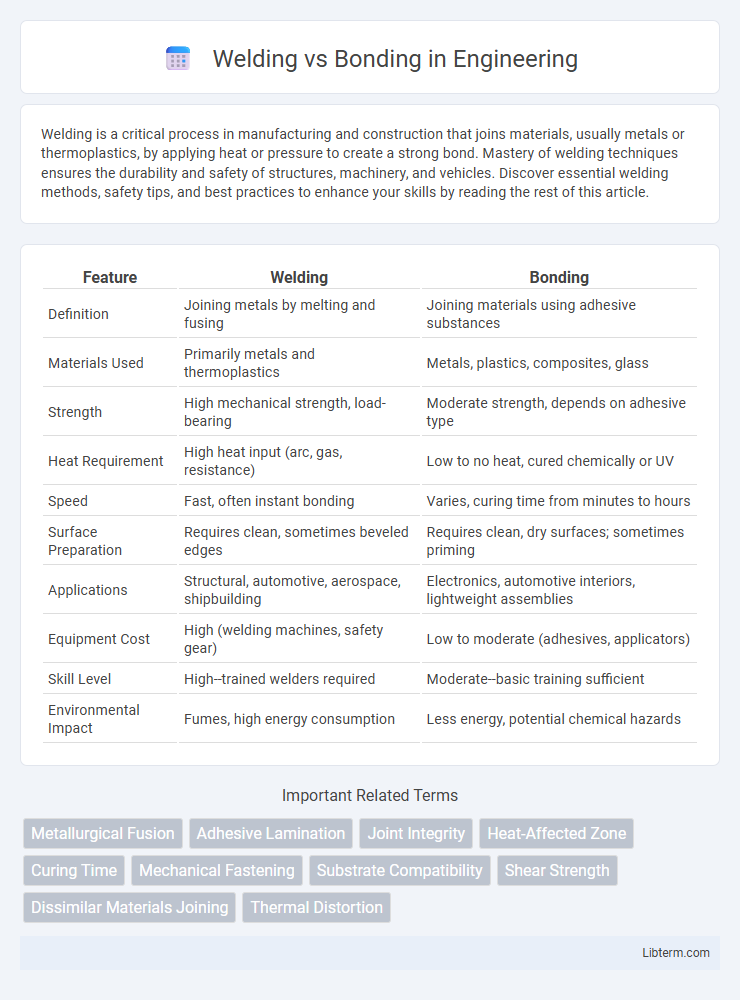

Table of Comparison

| Feature | Welding | Bonding |

|---|---|---|

| Definition | Joining metals by melting and fusing | Joining materials using adhesive substances |

| Materials Used | Primarily metals and thermoplastics | Metals, plastics, composites, glass |

| Strength | High mechanical strength, load-bearing | Moderate strength, depends on adhesive type |

| Heat Requirement | High heat input (arc, gas, resistance) | Low to no heat, cured chemically or UV |

| Speed | Fast, often instant bonding | Varies, curing time from minutes to hours |

| Surface Preparation | Requires clean, sometimes beveled edges | Requires clean, dry surfaces; sometimes priming |

| Applications | Structural, automotive, aerospace, shipbuilding | Electronics, automotive interiors, lightweight assemblies |

| Equipment Cost | High (welding machines, safety gear) | Low to moderate (adhesives, applicators) |

| Skill Level | High--trained welders required | Moderate--basic training sufficient |

| Environmental Impact | Fumes, high energy consumption | Less energy, potential chemical hazards |

Introduction to Welding and Bonding

Welding and bonding are two fundamental techniques for joining materials across industries like automotive, aerospace, and manufacturing. Welding involves melting base metals using heat or pressure to create a strong, permanent joint, often applied to metals and thermoplastics. Bonding uses adhesives to chemically or physically join surfaces, offering flexibility in material combinations and typically requiring less heat than welding.

Fundamental Principles of Welding

Welding involves the fusion of materials, typically metals or thermoplastics, through the application of heat, pressure, or both, creating a strong, permanent joint by melting the base materials and often adding a filler metal. The fundamental principles of welding include heat generation, material melting, fusion at the joint interface, and controlled cooling to solidify the bond. This process ensures high structural integrity and mechanical strength compared to bonding methods that rely on adhesives or mechanical fastening.

Core Concepts of Bonding Techniques

Bonding techniques involve the use of adhesives or chemical agents to join materials by creating molecular links at the interface, enabling strong, flexible, and often lightweight connections. These methods include epoxy, polyurethane, and acrylic adhesives, each selected based on substrate type, environmental resistance, and load-bearing requirements. Unlike welding, bonding avoids melting or deforming base materials, making it ideal for delicate or dissimilar materials in automotive, aerospace, and electronics industries.

Key Differences Between Welding and Bonding

Welding involves melting and fusing materials, typically metals or thermoplastics, to create a strong, permanent joint through heat or pressure application. Bonding uses adhesives or chemical agents to join surfaces without melting, allowing for flexibility and compatibility with dissimilar materials. Key differences include the requirement of high temperatures in welding versus ambient conditions in bonding, and the resulting mechanical strength and durability, which is generally higher in welded joints.

Material Compatibility: Welding vs Bonding

Welding excels with metals and thermoplastics, creating strong joints by melting materials, making it ideal for steel, aluminum, and similar alloys. Bonding uses adhesives suited for diverse materials including plastics, composites, glass, and dissimilar metals, offering flexibility in joining materials that cannot withstand high heat. Material compatibility varies significantly; welding requires heat-resistant substrates while bonding accommodates heat-sensitive and mixed-material assemblies.

Strength and Durability Comparison

Welding creates a strong, permanent joint by melting base materials together, resulting in high tensile strength and excellent durability ideal for structural applications. Bonding, using adhesives or epoxies, provides flexibility and resistance to vibration but typically has lower shear strength compared to welded joints. For long-term durability and load-bearing capacity, welding outperforms bonding, especially in high-stress or high-temperature environments.

Cost Analysis: Welding vs Bonding

Welding typically involves higher initial equipment and energy costs but offers superior strength and durability for heavy-duty applications. Bonding, especially with advanced adhesives, presents a lower upfront expense and reduced labor time, making it cost-effective for lightweight or complex assemblies. Evaluating total lifecycle costs, including maintenance and material compatibility, is critical for choosing between welding and bonding in manufacturing processes.

Application Suitability in Various Industries

Welding suits heavy industries like automotive, aerospace, and construction due to its strong, permanent metal joints ideal for high-stress applications. Bonding excels in electronics, medical devices, and lightweight manufacturing by joining dissimilar materials without heat-induced distortion. Industry-specific material compatibility and structural requirements determine the choice between welding and bonding for optimal performance.

Safety Considerations and Environmental Impact

Welding involves high temperatures and sparks, posing risks such as burns, eye damage, and inhalation of hazardous fumes, requiring strict safety gear and ventilation. Bonding, commonly using adhesives or resins, eliminates heat hazards but may expose workers to chemical vapors, necessitating proper handling and protective measures. From an environmental perspective, welding consumes significant energy and may release toxic gases, while bonding relies on chemical substances that could be volatile organic compounds (VOCs), influencing waste disposal and air quality management.

Choosing the Right Method: Factors to Consider

Selecting between welding and bonding depends on factors such as material type, joint strength requirements, and environmental conditions. Welding is ideal for metals requiring high structural integrity and heat resistance, while bonding suits dissimilar materials and applications demanding flexibility and vibration damping. Consider production speed, cost, and post-processing needs to determine the most efficient and durable joining method.

Welding Infographic

libterm.com

libterm.com