Flat slabs offer a streamlined structural design that eliminates the need for beams, providing a smooth ceiling surface and allowing for faster construction. They enhance architectural flexibility and optimize space usage, making them ideal for commercial and residential buildings. Discover how flat slabs can benefit your next project by exploring the detailed insights in this article.

Table of Comparison

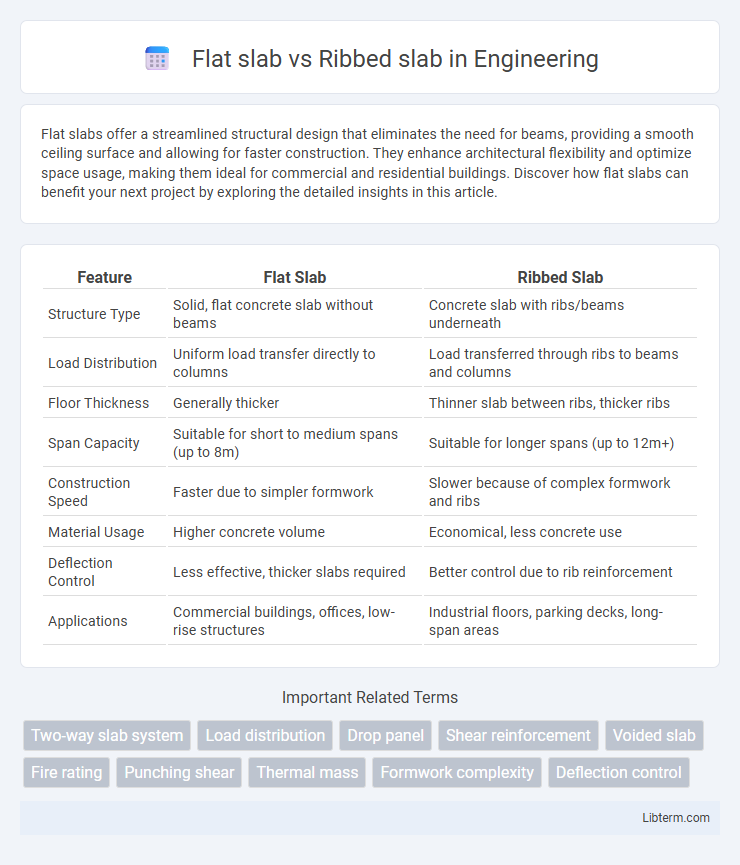

| Feature | Flat Slab | Ribbed Slab |

|---|---|---|

| Structure Type | Solid, flat concrete slab without beams | Concrete slab with ribs/beams underneath |

| Load Distribution | Uniform load transfer directly to columns | Load transferred through ribs to beams and columns |

| Floor Thickness | Generally thicker | Thinner slab between ribs, thicker ribs |

| Span Capacity | Suitable for short to medium spans (up to 8m) | Suitable for longer spans (up to 12m+) |

| Construction Speed | Faster due to simpler formwork | Slower because of complex formwork and ribs |

| Material Usage | Higher concrete volume | Economical, less concrete use |

| Deflection Control | Less effective, thicker slabs required | Better control due to rib reinforcement |

| Applications | Commercial buildings, offices, low-rise structures | Industrial floors, parking decks, long-span areas |

Introduction to Flat Slab and Ribbed Slab Systems

Flat slab systems feature a uniform thickness slab supported directly by columns without beams, enabling faster construction and flexible interior layouts, commonly used in commercial and residential buildings. Ribbed slab systems consist of a thin slab supported by parallel beams or ribs, reducing weight and material use while providing greater span capacity and improved load distribution. Both systems optimize structural efficiency but differ in complexity, cost, and architectural flexibility depending on project requirements.

Structural Overview of Flat Slab

Flat slabs consist of reinforced concrete slabs supported directly by columns without beams, providing a uniform thickness and creating a smooth ceiling surface ideal for architectural flexibility. The structural system enables efficient load distribution through two-way bending, reducing slab thickness and minimizing formwork costs compared to ribbed slabs, which incorporate ribs or beams to enhance stiffness. This design simplifies construction and facilitates faster erection while accommodating heavy loads and varying column layouts commonly used in commercial and residential buildings.

Structural Overview of Ribbed Slab

Ribbed slabs consist of a series of reinforced concrete beams, or ribs, running in one direction with a thin concrete topping, offering enhanced load distribution and reduced weight compared to flat slabs. This structural system improves span capacity and stiffness while minimizing materials, making it ideal for long spans in commercial and industrial buildings. The ribs act as primary load-carrying elements, efficiently transferring loads to columns and foundations, which enhances overall structural performance.

Material Efficiency Comparison

Flat slabs require less formwork and reduce concrete volume compared to ribbed slabs, offering simpler construction and minimized material wastage. Ribbed slabs use less concrete overall due to reduced slab thickness between ribs but demand more steel reinforcement for ribs, impacting total material consumption. Optimizing material efficiency depends on project-specific factors like load requirements, span length, and labor costs, with flat slabs favoring speed and simplicity while ribbed slabs emphasize structural economy.

Load Distribution Characteristics

Flat slabs distribute loads directly from the slab to the columns without the need for beams, resulting in a uniform load transfer and reduced bending moments. Ribbed slabs, incorporating beams or ribs beneath the slab, channel loads more effectively along the ribs, enhancing load-carrying capacity and reducing slab thickness. The load distribution in ribbed slabs allows for better handling of concentrated loads and spans longer distances compared to flat slabs.

Construction Techniques and Speed

Flat slabs enable faster construction due to the elimination of beams and simpler formwork, which reduces labor and material costs. Ribbed slabs require additional formwork and reinforcement for ribs, increasing complexity and construction time but offering better load distribution and reduced slab weight. The choice between flat and ribbed slabs depends on project deadlines and structural requirements, with flat slabs favored for speed and ribbed slabs suited for longer spans and heavier loads.

Cost Implications and Budgeting

Flat slabs generally incur higher initial formwork and concrete costs due to the absence of beams, but they reduce overall project expenses by minimizing floor-to-floor height and accelerating construction speed. Ribbed slabs offer material savings through reduced concrete volume and lighter weight, lowering foundation and structural costs while necessitating more complex formwork and longer labor hours. Budget decisions should balance the higher upfront expenses of flat slabs against the long-term savings in construction time and architectural flexibility compared to the cost-efficiency but labor-intensive nature of ribbed slabs.

Acoustic and Fire Performance

Flat slabs provide superior acoustic insulation due to their continuous surface, minimizing sound transmission and vibrations, while ribbed slabs can create more noise paths because of their discontinuous structure. Fire performance in flat slabs benefits from uniform thickness, offering better resistance and slower heat transfer, whereas ribbed slabs, with thinner webbed sections, may exhibit reduced fire resistance. Both systems can be enhanced with fireproof coatings and acoustic treatments, but inherent structural properties make flat slabs generally more effective for acoustic and fire safety in building design.

Typical Applications and Suitability

Flat slabs are ideal for commercial buildings, hospitals, and residential apartments where large column-free spaces are required, offering simplicity in formwork and faster construction. Ribbed slabs suit industrial structures, auditoriums, and long-span parking garages due to their enhanced load-bearing capacity and reduced material usage. The choice depends on the architectural demands, load requirements, and construction speed priorities.

Advantages and Disadvantages Summary

Flat slabs offer simpler formwork and faster construction times due to their uniform thickness, making them ideal for buildings with lower floor-to-floor heights, but they have limited load-carrying capacity and higher material usage compared to ribbed slabs. Ribbed slabs provide better strength and load distribution with reduced weight, allowing longer spans and cost savings in concrete, but require more complex formwork and longer construction durations. Choosing between flat and ribbed slabs depends on structural requirements, budget constraints, and architectural design considerations.

Flat slab Infographic

libterm.com

libterm.com