Orientation tolerance defines the allowable deviation from a specified angle or direction in manufacturing and assembly processes, ensuring parts fit and function correctly. Maintaining tight orientation tolerance improves product quality, reduces rework, and enhances overall performance. Explore the rest of the article to understand how optimizing orientation tolerance can benefit your projects.

Table of Comparison

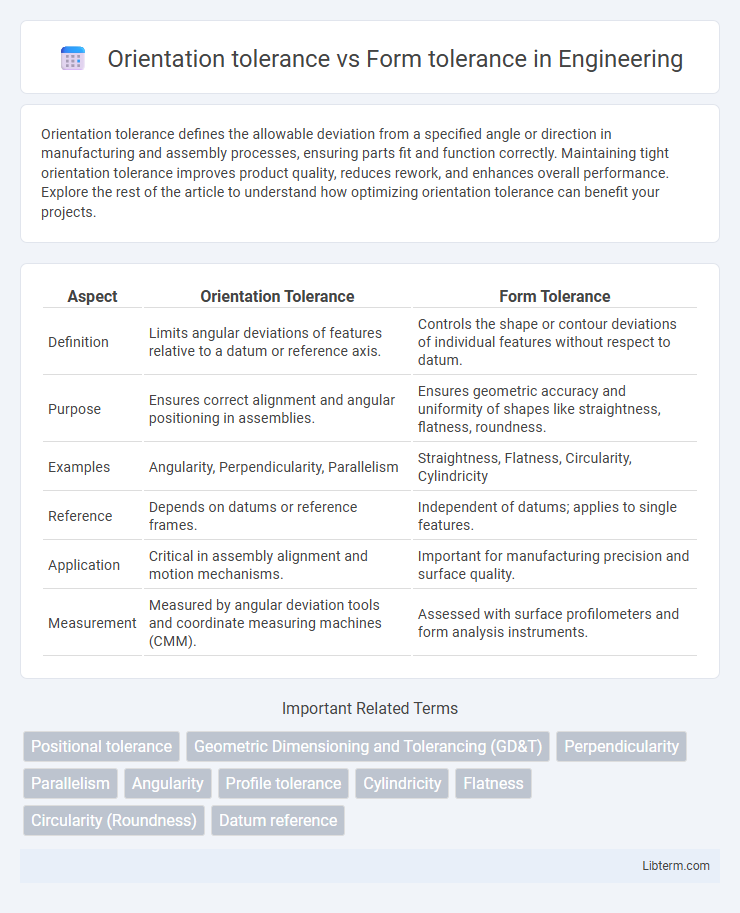

| Aspect | Orientation Tolerance | Form Tolerance |

|---|---|---|

| Definition | Limits angular deviations of features relative to a datum or reference axis. | Controls the shape or contour deviations of individual features without respect to datum. |

| Purpose | Ensures correct alignment and angular positioning in assemblies. | Ensures geometric accuracy and uniformity of shapes like straightness, flatness, roundness. |

| Examples | Angularity, Perpendicularity, Parallelism | Straightness, Flatness, Circularity, Cylindricity |

| Reference | Depends on datums or reference frames. | Independent of datums; applies to single features. |

| Application | Critical in assembly alignment and motion mechanisms. | Important for manufacturing precision and surface quality. |

| Measurement | Measured by angular deviation tools and coordinate measuring machines (CMM). | Assessed with surface profilometers and form analysis instruments. |

Understanding Geometric Dimensioning and Tolerancing (GD&T)

Orientation tolerance in GD&T controls the tilt or the angular relationship of a feature relative to a datum, ensuring parts fit and function correctly in assembly. Form tolerance refers to the shape accuracy of a feature, such as flatness or roundness, without referencing other features. Understanding the distinction between these tolerances is crucial for precise manufacturing and quality control in mechanical design.

Defining Orientation Tolerance

Orientation tolerance defines the permissible angular deviation of a feature's axis or median plane from its specified orientation, ensuring proper alignment in assemblies. It controls the tilt or angular displacement relative to a datum, critical for functional relationships between parts. Orientation tolerance differs from form tolerance, which governs the shape accuracy of individual features without reference to other elements.

Defining Form Tolerance

Form tolerance defines the allowable deviation in the shape or profile of a single feature without considering its orientation or location, ensuring the feature's geometric accuracy such as straightness, flatness, circularity, or cylindricity. Orientation tolerance, by contrast, controls the tilt or angle of a feature relative to a datum, affecting how the feature is positioned rather than its intrinsic shape. Understanding that form tolerance strictly governs the pure geometry of a part's feature is essential for maintaining manufacturing precision and functional fit.

Key Differences Between Orientation and Form Tolerance

Orientation tolerance controls the angular relationship between features, ensuring parts maintain correct alignment within specified angular limits. Form tolerance restricts the shape of individual features by controlling deviations such as flatness, straightness, roundness, and cylindricity, focusing on the feature's geometry without reference to other elements. The key difference lies in orientation tolerance managing relative angles between features, while form tolerance governs the perfection of a single feature's shape independently.

Types of Orientation Tolerances

Orientation tolerance types include angularity, perpendicularity, and parallelism, which control the tilt or angle of features relative to datum references. Angularity tolerance specifies the exact angle a surface or feature must maintain, perpendicularity ensures a 90-degree relationship, and parallelism mandates consistent distance between two features in a specified direction. These orientation tolerances differ from form tolerances, which control the shape of features without reference to datum, focusing solely on surface irregularities.

Types of Form Tolerances

Form tolerance types include flatness, straightness, circularity, and cylindricity, each controlling deviations in the shape of a single feature without reference to other features. Orientation tolerance, by contrast, controls the tilt or angle of a feature relative to a datum and includes types such as parallelism, perpendicularity, and angularity. Understanding these distinctions ensures precise geometric control in manufacturing and inspection processes.

Importance of Orientation Tolerance in Manufacturing

Orientation tolerance controls the angular variation of a feature relative to a datum, ensuring precise alignment critical for assembly and function in manufacturing processes. Maintaining strict orientation tolerance minimizes part misalignment, reducing wear, improving product performance, and enhancing overall quality control. Unlike form tolerance, which governs shape imperfections, orientation tolerance directly impacts how components fit and operate within assemblies, making it essential for high-precision manufacturing.

Importance of Form Tolerance in Product Quality

Form tolerance defines the acceptable limits for the shape of individual features, such as straightness, flatness, circularity, and cylindricity, ensuring precise geometry essential for proper function. Orientation tolerance controls the angle or tilt of features relative to a datum, but deviations in form can lead to functional failures regardless of correct orientation. Maintaining strict form tolerance is crucial for product quality because it directly affects the fit, assembly, and performance of mechanical components, reducing defects and enhancing reliability.

Choosing Between Orientation and Form Tolerance

Choosing between orientation tolerance and form tolerance depends on the functional requirements of a part. Orientation tolerance controls the tilt, angle, or direction of features relative to a datum, ensuring proper assembly and function, while form tolerance governs the shape accuracy such as straightness, flatness, or circularity of individual features without reference to other features. Opting for orientation tolerance is essential when the relationship between surfaces affects performance, whereas form tolerance is critical for ensuring the intrinsic geometry of a single feature meets design specifications.

Best Practices for Applying Orientation and Form Tolerances

Orientation tolerance controls the permissible angular deviation between features, crucial for maintaining precise alignment in assemblies, while form tolerance restricts geometric imperfections like straightness, flatness, or roundness of individual features. Best practices for applying these tolerances include specifying orientation tolerances only when feature alignment is functionally critical and using form tolerances to control individual feature perfection without over-constraining manufacturing processes. Balancing the application of these tolerances ensures functional performance and manufacturability by avoiding unnecessary constraints that could increase production complexity and cost.

Orientation tolerance Infographic

libterm.com

libterm.com