Thermal efficiency measures how effectively a system converts heat into useful work, which is crucial for optimizing energy consumption and reducing costs. It plays a significant role in industries such as power generation, automotive, and heating systems, impacting both performance and environmental footprint. Discover how improving thermal efficiency can benefit your operations by exploring the detailed insights in the rest of this article.

Table of Comparison

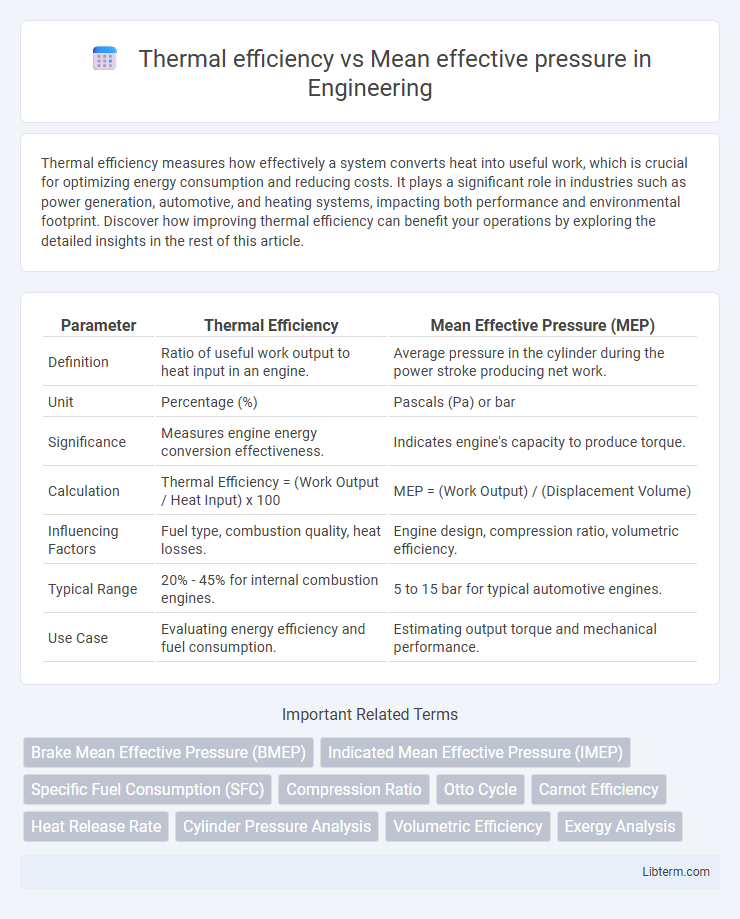

| Parameter | Thermal Efficiency | Mean Effective Pressure (MEP) |

|---|---|---|

| Definition | Ratio of useful work output to heat input in an engine. | Average pressure in the cylinder during the power stroke producing net work. |

| Unit | Percentage (%) | Pascals (Pa) or bar |

| Significance | Measures engine energy conversion effectiveness. | Indicates engine's capacity to produce torque. |

| Calculation | Thermal Efficiency = (Work Output / Heat Input) x 100 | MEP = (Work Output) / (Displacement Volume) |

| Influencing Factors | Fuel type, combustion quality, heat losses. | Engine design, compression ratio, volumetric efficiency. |

| Typical Range | 20% - 45% for internal combustion engines. | 5 to 15 bar for typical automotive engines. |

| Use Case | Evaluating energy efficiency and fuel consumption. | Estimating output torque and mechanical performance. |

Introduction to Thermal Efficiency and Mean Effective Pressure

Thermal efficiency measures how effectively an engine converts heat from fuel into mechanical work, expressed as a percentage of energy output versus input. Mean effective pressure (MEP) represents an average pressure in the engine's cylinders during the power stroke, serving as an indicator of engine performance and work output per cycle. Understanding the relationship between thermal efficiency and MEP is crucial for optimizing engine design and fuel consumption.

Defining Thermal Efficiency in Internal Combustion Engines

Thermal efficiency in internal combustion engines measures the engine's ability to convert the energy in fuel into useful work, typically expressed as a ratio of work output to heat input. Mean effective pressure (MEP) represents the average pressure in the combustion chamber during the power stroke and serves as an indicator of engine performance. Higher thermal efficiency often correlates with increased MEP, reflecting improved combustion and power generation capabilities.

Understanding Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) represents the average pressure exerted on the piston during the power stroke of an engine cycle, serving as a crucial indicator of engine performance. Higher MEP typically correlates with improved thermal efficiency, as it reflects the engine's ability to convert fuel energy into mechanical work more effectively. Measuring MEP helps engineers optimize combustion parameters and engine design for enhanced fuel economy and power output.

Importance of Thermal Efficiency and MEP in Engine Performance

Thermal efficiency directly measures an engine's ability to convert fuel energy into useful work, impacting fuel economy and emissions. Mean effective pressure (MEP) represents the average pressure in the combustion chamber, correlating with the engine's torque output and overall power performance. Optimizing both thermal efficiency and MEP is critical for enhancing engine performance, maximizing power output, and minimizing fuel consumption.

Mathematical Relationship Between Thermal Efficiency and MEP

Thermal efficiency (e) of an engine is mathematically related to the Mean Effective Pressure (MEP) through the brake power output and fuel energy input. The relationship can be expressed as e = (Brake Power) / (Fuel Energy Input) and since MEP = (Brake Power) / (Displacement Volume x Engine Speed), higher MEP values generally indicate increased thermal efficiency under constant fuel energy conditions. Optimizing MEP directly impacts thermal efficiency by maximizing work output per cycle relative to the energy supplied by the fuel.

Factors Influencing Thermal Efficiency and Mean Effective Pressure

Thermal efficiency in internal combustion engines is influenced by factors such as combustion temperature, fuel-air mixture quality, and heat losses within the engine, which directly affect the mean effective pressure (MEP). Higher mean effective pressure indicates better engine performance as it reflects the average pressure exerted on the pistons during the power stroke, influenced by combustion efficiency, friction losses, and engine design parameters. Optimizing combustion processes, improving fuel quality, and reducing mechanical losses are critical to maximizing both thermal efficiency and mean effective pressure for enhanced engine output.

Comparative Analysis: Thermal Efficiency vs Mean Effective Pressure

Thermal efficiency increases with higher mean effective pressure (MEP), as greater MEP indicates improved engine work output relative to fuel energy input. Comparative analysis shows engines operating at elevated MEP levels achieve better combustion efficiency and lower heat losses, enhancing overall thermal performance. Optimizing engine design to maximize MEP directly contributes to improved thermal efficiency by leveraging pressure cycles for more effective energy conversion.

Practical Implications in Engine Design and Operation

Thermal efficiency in engines directly correlates with mean effective pressure (MEP), as higher MEP values typically indicate better fuel conversion and energy output. Optimizing MEP through precise combustion chamber design, fuel injection timing, and turbocharging enhances thermal efficiency, leading to improved engine performance and reduced fuel consumption. Engine designers prioritize balancing MEP to achieve maximum thermal efficiency while maintaining durability and emissions compliance in practical applications.

Strategies to Optimize Both Thermal Efficiency and MEP

Optimizing thermal efficiency and mean effective pressure (MEP) requires precise calibration of fuel injection timing and air-fuel ratio to enhance combustion quality and reduce heat losses. Implementing advanced turbocharging and intercooling systems increases air density, thereby boosting MEP while maintaining higher thermal efficiency. Utilizing variable valve timing and exhaust gas recirculation (EGR) helps control in-cylinder temperatures, minimizing energy wastage and maximizing power output.

Future Trends in Improving Thermal Efficiency and Mean Effective Pressure

Future trends in improving thermal efficiency and mean effective pressure emphasize advanced combustion technologies such as homogeneous charge compression ignition (HCCI) and controlled auto-ignition (CAI) to optimize fuel-air mixing and reduce heat losses. Integration of variable valve timing (VVT) and turbocharging increases mean effective pressure while lowering fuel consumption and emissions. Electrification strategies combined with real-time engine control algorithms focus on maximizing thermal efficiency and mean effective pressure for sustainable powertrain performance.

Thermal efficiency Infographic

libterm.com

libterm.com