Spot weld is a crucial joining technique used in manufacturing to fuse overlapping metal sheets by applying heat and pressure at specific points. This method ensures strong, localized bonds without distorting the entire workpiece, making it ideal for automotive and aerospace industries. Discover how spot weld technology can enhance the quality and durability of your metal assemblies by reading the full article.

Table of Comparison

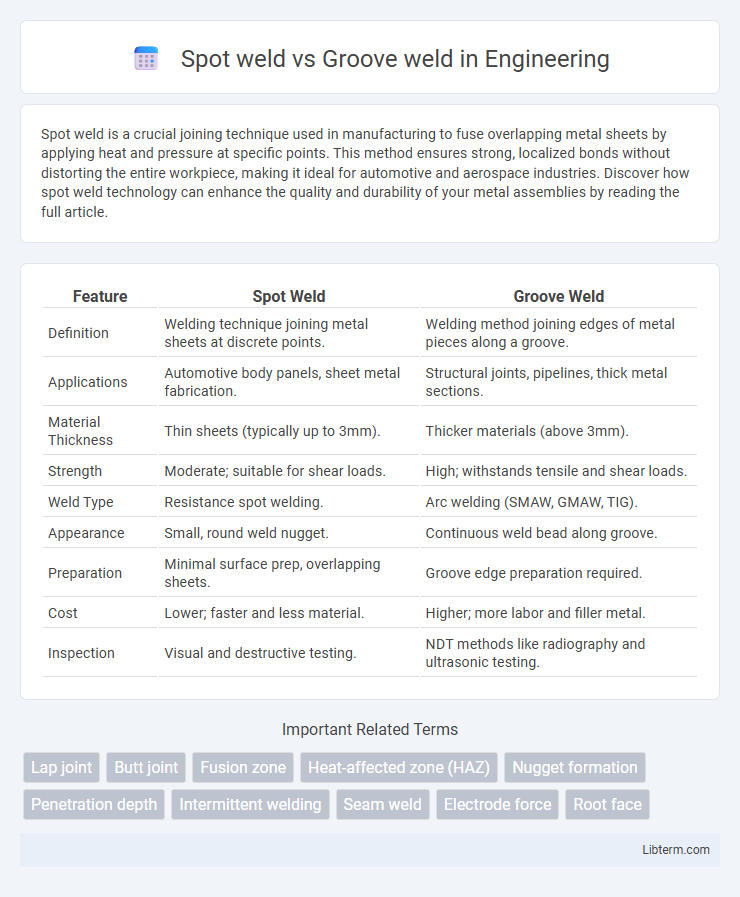

| Feature | Spot Weld | Groove Weld |

|---|---|---|

| Definition | Welding technique joining metal sheets at discrete points. | Welding method joining edges of metal pieces along a groove. |

| Applications | Automotive body panels, sheet metal fabrication. | Structural joints, pipelines, thick metal sections. |

| Material Thickness | Thin sheets (typically up to 3mm). | Thicker materials (above 3mm). |

| Strength | Moderate; suitable for shear loads. | High; withstands tensile and shear loads. |

| Weld Type | Resistance spot welding. | Arc welding (SMAW, GMAW, TIG). |

| Appearance | Small, round weld nugget. | Continuous weld bead along groove. |

| Preparation | Minimal surface prep, overlapping sheets. | Groove edge preparation required. |

| Cost | Lower; faster and less material. | Higher; more labor and filler metal. |

| Inspection | Visual and destructive testing. | NDT methods like radiography and ultrasonic testing. |

Introduction to Spot Weld and Groove Weld

Spot weld joins two overlapping metal sheets by applying pressure and heat at localized points, creating strong, precise connections ideal for sheet metal fabrication. Groove weld involves welding along the edges or grooves of joint preparations such as butt joints, allowing deeper penetration and higher strength in thicker materials. Spot welds excel in rapid, repetitive assembly, while groove welds provide comprehensive fusion for structural integrity.

Definition and Basic Principles

Spot weld is a resistance welding process that joins overlapping metal surfaces by applying heat generated from electrical resistance and pressure through electrodes, creating a localized weld nugget. Groove weld involves joining metal parts by filling a prepared groove between the base materials with molten filler metal, produced by arc welding techniques like SMAW, GMAW, or TIG. Spot welds emphasize rapid, localized fusion, whereas groove welds provide continuous, structural joints suited for thicker sections.

Common Applications in Industry

Spot welds are commonly used in automotive manufacturing for joining sheet metals due to their speed and efficiency in creating strong, localized bonds. Groove welds find widespread application in structural steel fabrication and pipeline construction where the joint requires full penetration and high strength. Both welding techniques are critical in industries like aerospace, shipbuilding, and heavy machinery, with spot welds suited for thin materials and groove welds preferred for thicker sections requiring durable, load-bearing joints.

Materials Suitable for Each Weld Type

Spot welds are ideal for thin sheet metals such as steel, stainless steel, and aluminum, commonly used in automotive and appliance manufacturing due to their ability to join materials without penetrating through the entire thickness. Groove welds accommodate thicker materials like carbon steel, stainless steel, and cast iron, providing deep weld penetration essential for load-bearing structures and heavy fabrication. Selecting spot welds for lightweight assemblies and groove welds for structural components ensures optimal strength and material compatibility in welding applications.

Equipment and Techniques Required

Spot welds require specialized spot welding machines equipped with copper electrodes delivering precise, high-current pulses to fuse overlapping metal sheets, commonly used in automotive assembly for quick, strong joints. Groove welds necessitate more versatile equipment such as arc welders (MIG, TIG, or stick welding machines) capable of deeper penetration and filler metal application to join edges or grooves with various joint designs. The techniques for spot welding rely on controlled pressure and timed current application, while groove welding demands skilled manipulation of the welding torch and filler wire to ensure proper fusion and structural integrity.

Strength and Durability Comparison

Spot welds provide localized strength ideal for joining sheet metals, offering quick assembly with moderate durability under shear forces. Groove welds deliver superior strength and enhanced durability by penetrating the joint fully, making them suitable for load-bearing applications and dynamic stresses. The choice between spot and groove welds depends on structural requirements, with groove welds generally outperforming spot welds in terms of long-term strength and resistance to fatigue.

Cost and Efficiency Considerations

Spot welds typically incur lower costs due to faster application times and reduced material use, making them ideal for high-volume production. Groove welds demand more skilled labor and longer processing times, increasing overall expenses, but provide superior joint strength and versatility for thicker materials. Choosing between them hinges on balancing budget constraints with the required structural performance and production efficiency.

Advantages and Disadvantages

Spot welds offer quick application and strong localized joints, making them ideal for thin sheet metals in automotive and manufacturing industries. Groove welds provide deeper penetration and greater strength for thicker materials but require more time and skill. Spot welding can lead to weaker joints under dynamic loads, while groove welds may increase welding costs and complexity.

Quality Control and Inspection Methods

Spot weld quality control relies heavily on visual inspection and ultrasonic testing (UT) to detect surface cracks and internal discontinuities, ensuring joint integrity in sheet metal assemblies. Groove weld inspection employs more comprehensive methods such as radiographic testing (RT) and magnetic particle inspection (MPI) to identify subsurface defects, lack of fusion, and porosity critical for load-bearing structures. Both weld types require adherence to specific acceptance criteria standardized by AWS and ISO to guarantee consistent mechanical performance and structural safety.

Choosing the Right Weld for Your Project

Spot welds provide fast, localized joining ideal for sheet metal with minimal distortion, making them perfect for automotive and appliance manufacturing. Groove welds offer deeper penetration and stronger joints suitable for thicker materials and structural applications. Choosing between spot and groove welds depends on material thickness, joint strength requirements, and the specific demands of your project.

Spot weld Infographic

libterm.com

libterm.com