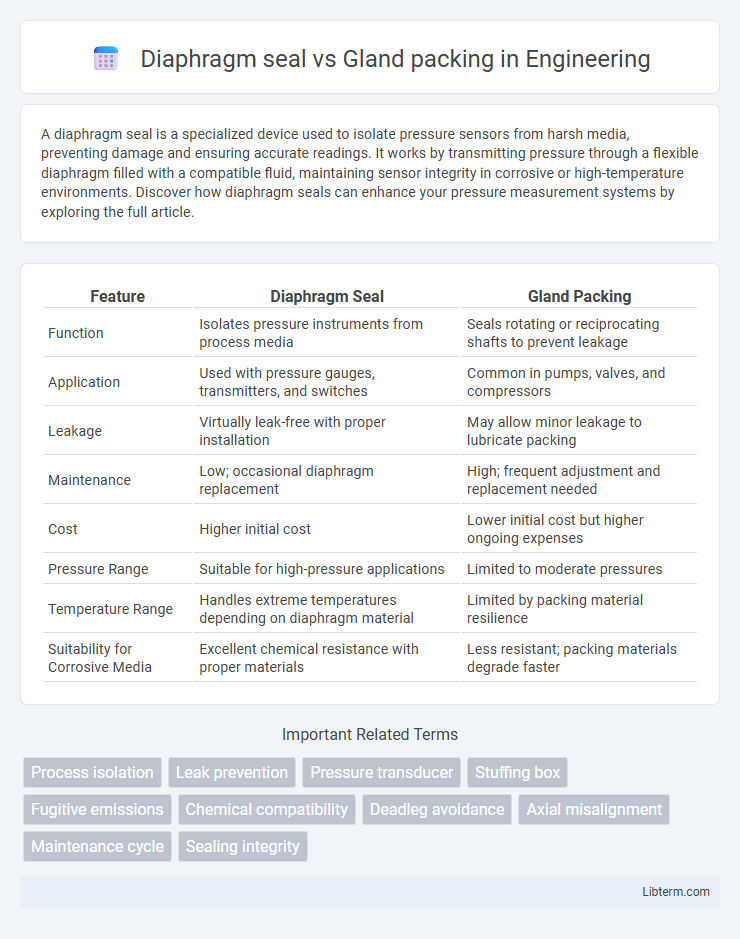

A diaphragm seal is a specialized device used to isolate pressure sensors from harsh media, preventing damage and ensuring accurate readings. It works by transmitting pressure through a flexible diaphragm filled with a compatible fluid, maintaining sensor integrity in corrosive or high-temperature environments. Discover how diaphragm seals can enhance your pressure measurement systems by exploring the full article.

Table of Comparison

| Feature | Diaphragm Seal | Gland Packing |

|---|---|---|

| Function | Isolates pressure instruments from process media | Seals rotating or reciprocating shafts to prevent leakage |

| Application | Used with pressure gauges, transmitters, and switches | Common in pumps, valves, and compressors |

| Leakage | Virtually leak-free with proper installation | May allow minor leakage to lubricate packing |

| Maintenance | Low; occasional diaphragm replacement | High; frequent adjustment and replacement needed |

| Cost | Higher initial cost | Lower initial cost but higher ongoing expenses |

| Pressure Range | Suitable for high-pressure applications | Limited to moderate pressures |

| Temperature Range | Handles extreme temperatures depending on diaphragm material | Limited by packing material resilience |

| Suitability for Corrosive Media | Excellent chemical resistance with proper materials | Less resistant; packing materials degrade faster |

Introduction to Diaphragm Seal and Gland Packing

Diaphragm seals use a flexible membrane to isolate the instrument from the process fluid, providing protection against corrosive, viscous, or high-temperature media. Gland packing consists of braided material compressed around a shaft to prevent leaks while allowing rotary or reciprocating motion. Both methods ensure fluid containment but differ in design, application, and maintenance requirements.

How Diaphragm Seals Work

Diaphragm seals isolate the process fluid from pressure measurement instruments by using a flexible diaphragm that transmits pressure without direct contact with the media, preventing contamination and corrosion. The diaphragm deflects in response to pressure changes, transferring force to the fill fluid within the seal, which then moves the sensor or gauge mechanism to provide accurate readings. This design enables reliable pressure measurement in harsh or sanitary environments where gland packing would struggle due to leakage or wear.

How Gland Packing Functions

Gland packing functions by compressing a braided material around a valve stem or shaft to create a tight seal that prevents fluid leakage while allowing rotational or linear movement. It compensates for wear and thermal expansion through periodic tightening, maintaining effective sealing in pumps and valves. This sealing method contrasts with diaphragm seals, which use a flexible membrane to isolate process fluids from measuring instruments.

Key Differences Between Diaphragm Seal and Gland Packing

Diaphragm seals provide a flexible barrier protecting pressure sensors from corrosive or viscous fluids, ensuring accurate measurement with minimal maintenance, whereas gland packing uses pliable material to seal pump shafts and prevent fluid leakage but may require frequent adjustments due to wear. Unlike gland packing, diaphragm seals eliminate the risk of leakage and contamination, enhancing system reliability in critical applications such as chemical processing and pharmaceuticals. The choice between the two depends on factors like pressure range, media compatibility, and maintenance intervals, with diaphragm seals favored for high-precision and hygienic environments.

Advantages of Diaphragm Seals

Diaphragm seals provide superior protection against corrosion and contamination by isolating the measuring instrument from the process fluid, ensuring accurate and reliable pressure readings in harsh environments. They minimize leakage risks and reduce maintenance requirements compared to gland packing, which often suffers from wear and requires frequent adjustments. Additionally, diaphragm seals enhance instrument lifespan and performance by maintaining a contamination-free and hermetically sealed environment.

Advantages of Gland Packing

Gland packing offers superior sealing performance in high-pressure and high-temperature applications due to its ability to accommodate shaft movement while maintaining a tight seal. It provides cost-effective installation and maintenance with readily available materials, making it suitable for a broad range of industrial pumps and valves. The flexibility of gland packing allows for easy adjustment and repair without complete disassembly, reducing downtime and operational disruption.

Common Applications of Diaphragm Seals

Diaphragm seals are commonly used in harsh chemical processing environments, food and beverage industries, and pharmaceutical manufacturing to protect pressure sensors from corrosive, viscous, or abrasive media. These seals prevent process fluids from contacting instrumentation, ensuring accurate pressure measurements and extending equipment lifespan. Typical applications include hydraulic systems, sanitary processes, and hygienic pressure measurement tasks where contamination prevention is critical.

Typical Uses of Gland Packing

Gland packing is commonly used in industrial valves, pumps, and rotating equipment to provide a reliable seal around moving shafts or stems, preventing fluid leakage under varying pressure and temperature conditions. It is particularly effective in applications involving steam, water, oil, and gases in sectors like petrochemical, power generation, and manufacturing. Gland packing offers a cost-effective, adaptable sealing solution for maintenance-intensive environments where frequent adjustments may be required.

Maintenance and Reliability Comparison

Diaphragm seals require less frequent maintenance than gland packing because they effectively isolate the process fluid from the instrument, minimizing wear and leakage risks. Gland packing demands regular adjustments and replacements due to seal degradation and potential leakage, which can result in increased downtime and maintenance costs. The superior reliability of diaphragm seals stems from their leak-proof design and reduced mechanical stress, enhancing overall equipment lifespan and safety.

Choosing the Right Solution: Diaphragm Seal vs Gland Packing

Selecting between diaphragm seals and gland packing hinges on application-specific factors such as pressure, temperature, and media compatibility. Diaphragm seals excel in preventing fluid contamination and are ideal for corrosive or abrasive environments, offering enhanced leak resistance and minimal maintenance. Gland packing suits low to moderate pressure systems where cost efficiency and simplicity are priorities, but may require more frequent adjustments and inspections to maintain sealing integrity.

Diaphragm seal Infographic

libterm.com

libterm.com