Bevel gears transmit motion between intersecting shafts at various angles, commonly 90 degrees, enabling efficient torque transfer in machinery. Their conical shape allows smooth meshing and precise power transmission, which is essential for applications like automotive differentials and industrial equipment. Discover how bevel gears enhance your mechanical designs by reading the full article.

Table of Comparison

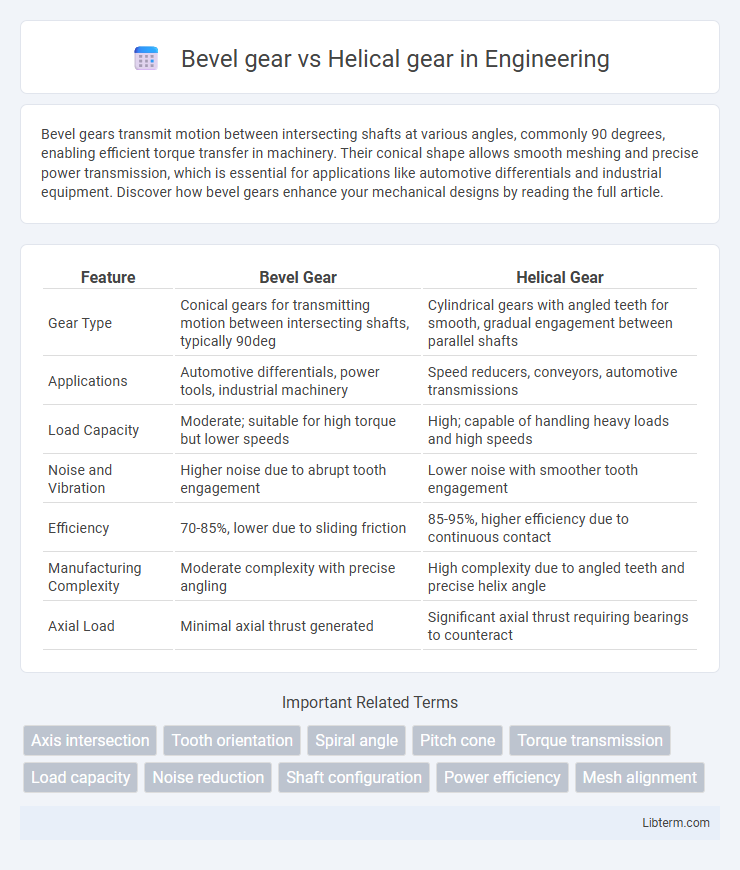

| Feature | Bevel Gear | Helical Gear |

|---|---|---|

| Gear Type | Conical gears for transmitting motion between intersecting shafts, typically 90deg | Cylindrical gears with angled teeth for smooth, gradual engagement between parallel shafts |

| Applications | Automotive differentials, power tools, industrial machinery | Speed reducers, conveyors, automotive transmissions |

| Load Capacity | Moderate; suitable for high torque but lower speeds | High; capable of handling heavy loads and high speeds |

| Noise and Vibration | Higher noise due to abrupt tooth engagement | Lower noise with smoother tooth engagement |

| Efficiency | 70-85%, lower due to sliding friction | 85-95%, higher efficiency due to continuous contact |

| Manufacturing Complexity | Moderate complexity with precise angling | High complexity due to angled teeth and precise helix angle |

| Axial Load | Minimal axial thrust generated | Significant axial thrust requiring bearings to counteract |

Introduction to Bevel and Helical Gears

Bevel gears transmit motion between intersecting shafts, typically at a 90-degree angle, featuring conically shaped teeth that enable smooth torque transfer in automotive differentials and industrial machinery. Helical gears have angled teeth cut at a helix angle, providing gradual engagement and quieter operation, making them ideal for high-speed applications and heavy-load power transmission in gearboxes and conveyors. Both gear types optimize mechanical efficiency by balancing load distribution, noise reduction, and torque capacity in diverse engineering systems.

Fundamental Design Differences

Bevel gears and helical gears differ fundamentally in their design and application; bevel gears feature conical shapes with teeth cut on an angled surface to transmit motion between intersecting shafts, typically at 90 degrees. Helical gears have angled teeth cut along a cylindrical surface, enabling smoother and quieter operation by allowing gradual tooth engagement and transmitting power between parallel or slightly angled shafts. The geometry of bevel gears facilitates changes in shaft direction, while helical gears optimize load capacity and speed in parallel configurations.

Working Principles

Bevel gears transmit torque between intersecting shafts by engaging conically shaped teeth that mesh at varying angles, typically 90 degrees, allowing smooth changes in shaft direction. Helical gears operate via angled teeth cut at a helix angle around the cylindrical gear body, creating gradual tooth engagement that provides quieter and more efficient power transmission along parallel or crossed axes. The spiral nature of helical gear teeth results in axial thrust, whereas bevel gears manage forces through their conical geometry for spatial shaft orientation.

Load Capacity Comparison

Bevel gears typically handle higher load capacities in applications requiring torque transmission at various angles, especially where right-angle drives are involved. Helical gears offer smoother operation and greater load distribution due to their angled teeth, resulting in higher load capacity compared to spur gears but generally lower than bevel gears in right-angle configurations. For axial and radial load handling, bevel gears excel in heavy-duty scenarios, while helical gears are preferred for parallel shaft applications with moderate to high loads.

Efficiency and Performance

Bevel gears offer high efficiency in transmitting power between intersecting shafts, typically achieving around 95-98% efficiency due to their direct tooth engagement and simpler geometry. Helical gears provide smoother operation and better load distribution because of their angled teeth, resulting in improved performance with slightly lower efficiency, usually around 94-96%, due to increased sliding friction. In high-speed and high-load applications, bevel gears excel in efficiency, while helical gears are preferred for quieter, more durable performance.

Noise and Vibration Levels

Bevel gears typically generate higher noise and vibration levels compared to helical gears due to their angular tooth design and point contact during rotation. Helical gears offer smoother and quieter operation because their angled teeth engage gradually, distributing load more evenly and reducing impact forces. Noise reduction and vibration control make helical gears preferable in precision machinery and automotive applications where minimal acoustic disturbance is critical.

Applications and Use Cases

Bevel gears are commonly used in automotive differentials, aerospace applications, and industrial machinery where the direction of a shaft's rotation needs to change, typically at a 90-degree angle. Helical gears find extensive use in automotive transmissions, conveyors, and elevators due to their ability to handle high speeds and loads with smoother and quieter operation. Both gear types offer high efficiency, but bevel gears excel in torque transfer at intersecting shafts, while helical gears are preferred for parallel shaft configurations and durability in continuous operation.

Installation and Maintenance

Bevel gears require precise alignment of shafts at specific angles, typically 90 degrees, making installation more complex compared to helical gears, which accommodate parallel or slightly crossed shafts with easier mounting. Maintenance of bevel gears demands regular lubrication and inspection for wear on teeth surfaces due to angular contact, whereas helical gears, with their angled teeth, typically experience smoother operation and less noise, reducing maintenance frequency. Proper installation of bevel gears ensures effective torque transmission in applications like differential drives, while helical gears excel in high-speed, high-load settings due to their durability and reduced vibration during maintenance checks.

Cost Considerations

Bevel gears typically incur higher manufacturing costs due to their complex geometry and precise angling requirements, especially when involving spiral bevel configurations. Helical gears offer cost advantages through simpler manufacturing processes and standardized production, making them more economical for high-volume applications. Material selection and application-specific load demands further influence the overall cost efficiency between bevel and helical gear systems.

Pros and Cons: Summary Table

Bevel gears excel in changing the axis of rotation and are ideal for right-angle power transmission, offering high torque and efficiency but tend to be noisier and less suitable for high-speed applications. Helical gears provide smoother and quieter operation with higher load capacity due to angled teeth, making them better for parallel or crossed shafts, though they generate axial thrust and require more complex bearings. The choice between bevel and helical gears depends on factors like shaft orientation, load requirements, noise sensitivity, and speed constraints.

Bevel gear Infographic

libterm.com

libterm.com