A driven well is a type of water well constructed by driving a small-diameter pipe into shallow water-bearing sand or gravel deposits. This cost-effective method is suitable for areas with loose soil and relatively shallow groundwater levels. Discover more about the benefits, installation process, and maintenance tips for your driven well in the full article.

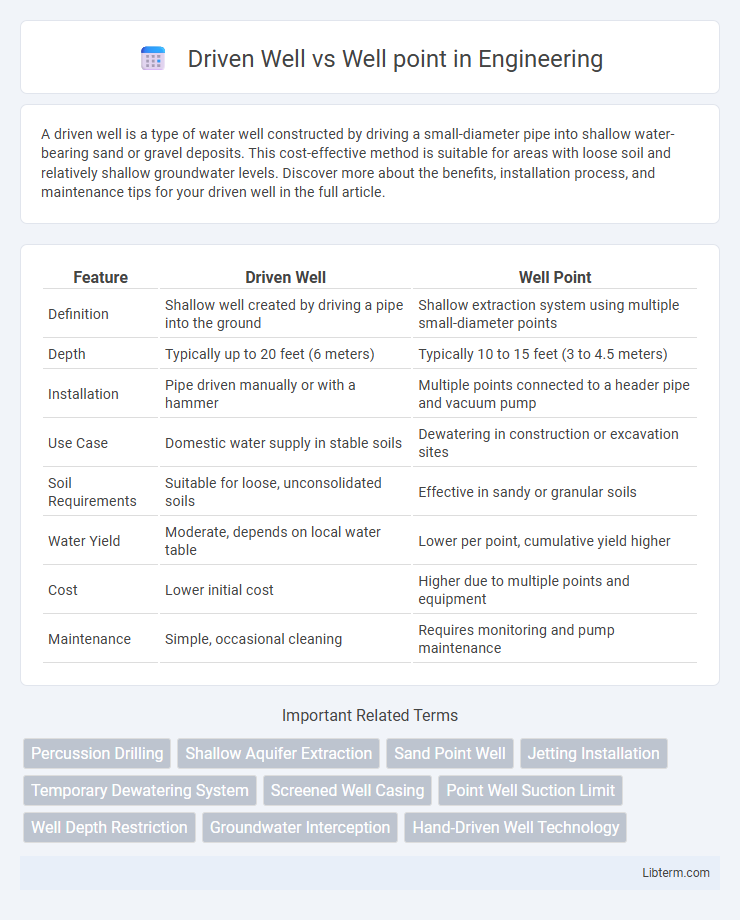

Table of Comparison

| Feature | Driven Well | Well Point |

|---|---|---|

| Definition | Shallow well created by driving a pipe into the ground | Shallow extraction system using multiple small-diameter points |

| Depth | Typically up to 20 feet (6 meters) | Typically 10 to 15 feet (3 to 4.5 meters) |

| Installation | Pipe driven manually or with a hammer | Multiple points connected to a header pipe and vacuum pump |

| Use Case | Domestic water supply in stable soils | Dewatering in construction or excavation sites |

| Soil Requirements | Suitable for loose, unconsolidated soils | Effective in sandy or granular soils |

| Water Yield | Moderate, depends on local water table | Lower per point, cumulative yield higher |

| Cost | Lower initial cost | Higher due to multiple points and equipment |

| Maintenance | Simple, occasional cleaning | Requires monitoring and pump maintenance |

Introduction to Driven Wells and Well Points

Driven wells are shallow groundwater extraction systems installed by driving a small-diameter pipe with a screened end into the water-bearing soil, commonly used for residential or agricultural water supply. Well points function as a similar dewatering method, consisting of a pipe with a perforated intake connected to a vacuum pump to temporarily lower the water table during construction projects. Both driven wells and well points utilize simple installation techniques and are cost-effective solutions for accessing or managing groundwater in unconsolidated soil formations.

Definition of Driven Wells

Driven wells are a type of water well constructed by driving a small-diameter pipe with a screened end into an underground water-bearing formation using a heavy hammering tool. This method is ideal for shallow groundwater access, typically less than 50 feet deep, and is commonly used in areas with loose soil or sand. Driven wells provide a cost-effective and quick solution for residential water supply, but are less suitable for deep or rocky terrains compared to drilled wells.

Definition of Well Point Systems

Well point systems consist of a series of small-diameter wells connected to a header pipe and vacuum pump to lower groundwater levels for excavation purposes. Driven wells, a subtype of well point systems, are installed by driving a pipe into the ground with a screened section at the bottom to collect groundwater. Well point systems effectively dewater soils in construction sites by creating a continuous groundwater extraction network.

Key Differences Between Driven Wells and Well Points

Driven wells are constructed by hammering a small-diameter pipe into the ground, tapping shallow aquifers, while well points involve a series of small-diameter tubes connected to a pump for dewatering purposes. Driven wells are typically used for water supply in unconsolidated formations, whereas well points are primarily employed to lower groundwater levels during excavation. The key differences lie in their installation methods, applications, and depth capabilities, with driven wells suited for water extraction and well points designed for temporary dewatering.

Installation Process: Driven Well vs Well Point

The installation process of driven wells involves driving a pipe with a screen into the ground using a hammer or other mechanical device, typically reaching greater depths in confined aquifers. Well points require the assembly of a series of small-diameter pipes with screened points, which are driven or jetted into shallow, loose, saturated soils to facilitate dewatering. Driven wells are generally faster and suitable for deeper water extraction, while well points are primarily used for temporary or shallow groundwater control applications.

Water Yield and Efficiency Comparison

Driven wells typically offer moderate water yield, ranging from 5 to 10 gallons per minute, making them suitable for shallow groundwater sources with high permeability. Well points, often employed in dewatering and construction applications, provide lower water yield but higher efficiency in extracting water from near-surface aquifers due to their shallow installation and clustered design. Efficiency comparison reveals driven wells excel in sustained water supply for residential use, while well points are optimized for temporary, high-efficiency dewatering tasks.

Applications and Suitable Soil Conditions

Driven wells are primarily used in sandy or loose soil conditions where the well screen can be easily driven into the aquifer, making them ideal for shallow water extraction in residential and agricultural applications. Well points are suitable for dewatering purposes in construction sites with saturated, fine-grained soils like silts and clays, providing temporary groundwater control by creating a localized lowered water table. Both methods excel in specific geotechnical environments, with driven wells favored for permanent water supply and well points for short-term groundwater management.

Maintenance Requirements and Challenges

Driven wells generally require more frequent maintenance due to their shallow depth and susceptibility to surface contaminants, which can lead to clogging and water quality issues. Well points, often used for dewatering purposes, face challenges such as corrosion, pump wear, and sediment buildup that necessitate regular inspection and cleaning. Both systems demand proactive maintenance schedules to ensure functionality and prevent operational downtime, with driven wells typically needing more rigorous attention in seasonal or high-demand conditions.

Cost Comparison: Driven Well vs Well Point

Driven wells typically have lower installation costs compared to well points due to simpler equipment and faster setup times, making them more cost-effective for shallow water extraction. Well points, while more expensive to install because of the multiple interconnected pipes and pump systems required, offer better efficiency in dewatering larger or deeper areas. Maintenance expenses for driven wells tend to be lower, but well points can provide longer-term operational savings in construction projects with significant groundwater management needs.

Choosing the Right Well System for Your Needs

Choosing the right well system depends on your water needs and site conditions; driven wells are cost-effective for shallow aquifers and stable soil, offering quick installation and reliable water flow. Well points excel in sandy or loose soil where dewatering or rapid water extraction is required, using multiple small-diameter pipes to efficiently lower water tables. Evaluate groundwater depth, soil type, and intended water use to determine the most efficient and sustainable well system for your project.

Driven Well Infographic

libterm.com

libterm.com