Diaphragm pumps use a flexible diaphragm to create a variable volume chamber, allowing efficient and precise fluid transfer without contamination. These pumps are ideal for handling abrasive, viscous, or chemically aggressive fluids in industries such as chemical processing, food production, and pharmaceuticals. Discover how choosing the right diaphragm pump can optimize your operations by exploring the full article.

Table of Comparison

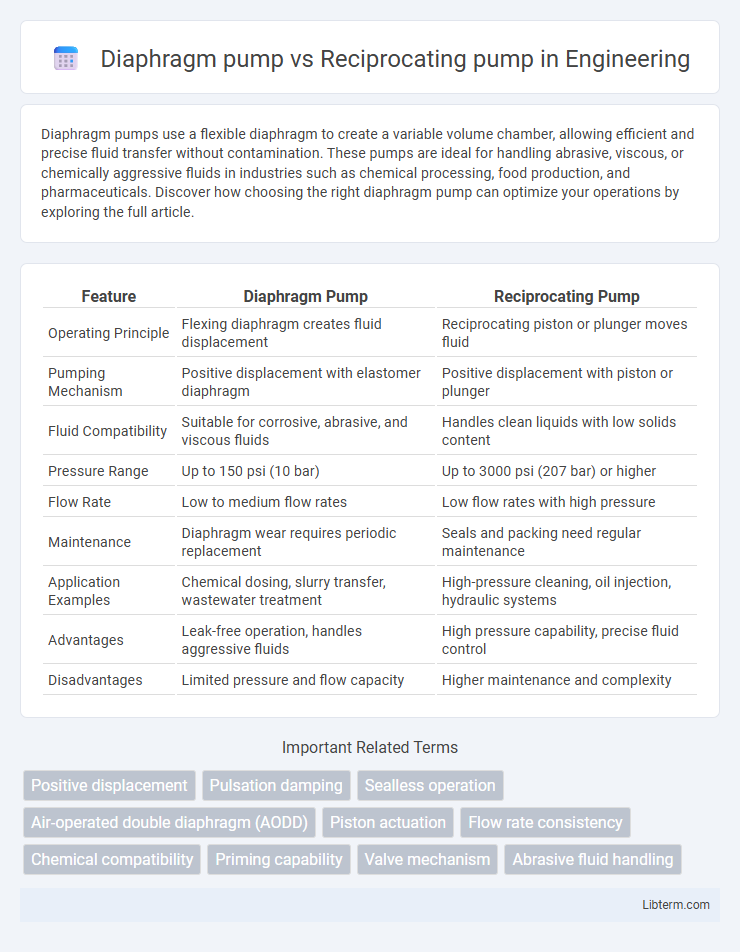

| Feature | Diaphragm Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Flexing diaphragm creates fluid displacement | Reciprocating piston or plunger moves fluid |

| Pumping Mechanism | Positive displacement with elastomer diaphragm | Positive displacement with piston or plunger |

| Fluid Compatibility | Suitable for corrosive, abrasive, and viscous fluids | Handles clean liquids with low solids content |

| Pressure Range | Up to 150 psi (10 bar) | Up to 3000 psi (207 bar) or higher |

| Flow Rate | Low to medium flow rates | Low flow rates with high pressure |

| Maintenance | Diaphragm wear requires periodic replacement | Seals and packing need regular maintenance |

| Application Examples | Chemical dosing, slurry transfer, wastewater treatment | High-pressure cleaning, oil injection, hydraulic systems |

| Advantages | Leak-free operation, handles aggressive fluids | High pressure capability, precise fluid control |

| Disadvantages | Limited pressure and flow capacity | Higher maintenance and complexity |

Introduction to Diaphragm and Reciprocating Pumps

Diaphragm pumps utilize a flexible membrane to create a variable volume chamber, enabling fluid transfer with excellent chemical compatibility and minimal contamination risk, making them ideal for aggressive or viscous fluids. Reciprocating pumps operate via a piston or plunger moving back and forth to displace fluid, providing high-pressure delivery and precise flow control suitable for applications requiring consistent, metered output. Both pump types excel in handling different fluid characteristics and pressure requirements, with diaphragm pumps favored for sealed, leak-free performance and reciprocating pumps valued for durability in high-pressure scenarios.

How Diaphragm Pumps Work

Diaphragm pumps operate by flexing a diaphragm to create a variable volume chamber, which draws in and expels fluid through check valves, enabling precise and leak-free pumping of viscous or abrasive fluids. These pumps use the diaphragm's reciprocating motion to displace liquid without the fluid contacting moving mechanical parts, enhancing chemical compatibility and reducing maintenance. In contrast, reciprocating pumps rely on pistons or plungers moving within cylinders, which typically involve direct fluid contact with mechanical components and more complex sealing requirements.

Working Principle of Reciprocating Pumps

Reciprocating pumps operate using a piston or plunger moving back and forth within a cylinder, creating a vacuum that draws fluid into the chamber during the suction stroke and then forces it out during the discharge stroke. This positive displacement mechanism enables high-pressure fluid delivery, making reciprocating pumps ideal for applications requiring precise flow rates and pressures. Unlike diaphragm pumps that rely on a flexible membrane, reciprocating pumps deliver fluid through direct mechanical action, resulting in consistent displacement and high efficiency in handling viscous or corrosive liquids.

Key Differences Between Diaphragm and Reciprocating Pumps

Diaphragm pumps use a flexible diaphragm that moves back and forth to create suction and discharge, enabling them to handle corrosive and abrasive fluids with minimal leakage risk. Reciprocating pumps rely on a piston or plunger mechanism, offering high pressure and precise flow control but typically requiring more maintenance due to mechanical wear. The key differences lie in their construction, fluid handling capabilities, and maintenance requirements, with diaphragm pumps favored for hazardous or viscous liquids and reciprocating pumps preferred for applications demanding high pressure and accuracy.

Applications of Diaphragm Pumps

Diaphragm pumps excel in handling corrosive, abrasive, and viscous fluids, making them ideal for chemical dosing, wastewater treatment, and food processing industries. Their ability to provide leak-free, airtight pumping suits applications requiring contamination-free transfer, such as pharmaceutical manufacturing and laboratory use. These pumps perform efficiently in hazardous or explosive environments due to their air-operated, seal-less design, which minimizes the risk of leaks and sparks.

Common Uses of Reciprocating Pumps

Reciprocating pumps are widely used in applications requiring high pressure and precise fluid control, such as in oil and gas pipelines, hydraulic systems, and chemical injection processes. They excel in dosing chemicals, pumping viscous fluids, and handling slurry or abrasive materials due to their ability to generate consistent flow rates under varying conditions. Industries including water treatment, petroleum refining, and food processing commonly employ reciprocating pumps for their reliability in metering and high-pressure transfer tasks.

Performance Comparison: Efficiency, Flow Rate, and Pressure

Diaphragm pumps exhibit high efficiency in handling viscous and abrasive fluids with flow rates typically ranging from 1 to 100 gallons per minute and pressures up to 150 psi, making them suitable for precise, low-flow applications. Reciprocating pumps deliver superior pressure performance, often exceeding 1000 psi, and maintain steady flow rates ideal for high-pressure industrial processes, albeit with slightly lower efficiency due to mechanical complexity. The choice between diaphragm and reciprocating pumps hinges on specific operational requirements, balancing efficiency, achievable flow rate, and pressure demands.

Maintenance and Durability Considerations

Diaphragm pumps feature minimal wear parts and operate with a sealed design, significantly reducing maintenance frequency and downtime compared to reciprocating pumps, which have multiple moving seals and valves requiring regular inspection and replacement. Durability-wise, diaphragm pumps excel in handling abrasive or corrosive fluids, as their elastomeric diaphragms resist chemical attack and eliminate internal leakage issues common in reciprocating pumps. Reciprocating pumps, while capable of high-pressure delivery, often face shorter service intervals due to mechanical friction and seal wear, necessitating more robust maintenance protocols to sustain longevity.

Cost Factors: Initial Investment and Operating Expenses

Diaphragm pumps generally have a lower initial investment due to simpler construction and fewer moving parts, reducing upfront purchase costs compared to reciprocating pumps. Operating expenses for diaphragm pumps tend to be lower as they require less maintenance and exhibit higher durability in handling abrasive or corrosive fluids. In contrast, reciprocating pumps involve higher energy consumption and frequent maintenance, increasing long-term operating costs despite potential efficiency benefits in high-pressure applications.

Choosing the Right Pump: Diaphragm vs Reciprocating

Choosing the right pump between diaphragm and reciprocating options depends on the application requirements such as fluid type, pressure, and flow rate. Diaphragm pumps excel in handling corrosive, abrasive, or viscous fluids with minimal leakage due to their sealed design, making them ideal for chemical transfer and slurry pumping. Reciprocating pumps provide consistent high pressure and precise flow control, suitable for high-pressure injection, water jetting, and hydraulic applications.

Diaphragm pump Infographic

libterm.com

libterm.com