The elastic limit is the maximum stress a material can withstand without undergoing permanent deformation, ensuring it returns to its original shape after the load is removed. Understanding the elastic limit is crucial in engineering and design to prevent structural failure and maintain safety. Discover how this fundamental concept impacts material selection and performance by reading the rest of the article.

Table of Comparison

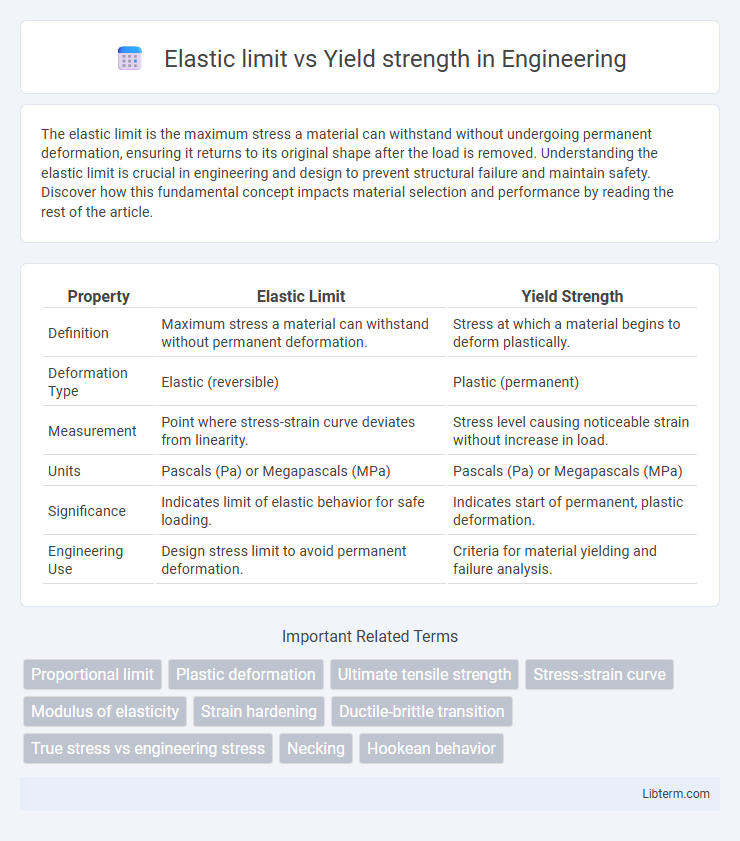

| Property | Elastic Limit | Yield Strength |

|---|---|---|

| Definition | Maximum stress a material can withstand without permanent deformation. | Stress at which a material begins to deform plastically. |

| Deformation Type | Elastic (reversible) | Plastic (permanent) |

| Measurement | Point where stress-strain curve deviates from linearity. | Stress level causing noticeable strain without increase in load. |

| Units | Pascals (Pa) or Megapascals (MPa) | Pascals (Pa) or Megapascals (MPa) |

| Significance | Indicates limit of elastic behavior for safe loading. | Indicates start of permanent, plastic deformation. |

| Engineering Use | Design stress limit to avoid permanent deformation. | Criteria for material yielding and failure analysis. |

Introduction to Elastic Limit and Yield Strength

The elastic limit is the maximum stress a material can withstand without permanent deformation, ensuring it returns to its original shape once the load is removed. Yield strength marks the stress level at which a material begins to deform plastically, resulting in irreversible deformation. Understanding the distinction between elastic limit and yield strength is crucial for designing materials that maintain structural integrity under varying loads.

Definition of Elastic Limit

The elastic limit is the maximum stress a material can withstand without undergoing permanent deformation, meaning it will return to its original shape once the load is removed. Yield strength marks the point at which a material begins to deform plastically and cannot fully regain its original form. Understanding the elastic limit is crucial for designing structures that must maintain integrity under stress without permanent damage.

Definition of Yield Strength

Yield strength defines the stress level at which a material begins to deform plastically, indicating a permanent change in shape. Elastic limit refers to the maximum stress a material can withstand without undergoing permanent deformation. Yield strength is crucial for engineering applications as it determines the safe load capacity before irreversible distortion occurs.

Key Differences Between Elastic Limit and Yield Strength

The elastic limit defines the maximum stress a material can withstand without permanent deformation, whereas yield strength indicates the stress at which a material begins to deform plastically and cannot return to its original shape. Elastic limit is typically lower or equal to yield strength and marks the boundary between elastic and plastic behavior on the stress-strain curve. Yield strength is a critical design parameter in engineering applications to ensure structural integrity beyond the elastic limit.

Importance in Material Science

Elastic limit defines the maximum stress a material can endure without permanent deformation, while yield strength marks the stress at which plastic deformation begins. Understanding these parameters is crucial in material science for designing structures that maintain integrity under load without permanent damage. Accurate knowledge of elastic limit and yield strength ensures safety, durability, and optimal performance of engineering materials.

Measurement Methods

Elastic limit and yield strength are crucial mechanical properties measured through tensile testing using a universal testing machine (UTM). The elastic limit is determined by identifying the maximum stress that a material can withstand without permanent deformation, often characterized by a linear stress-strain response. Yield strength measurement typically involves the offset method, such as the 0.2% offset technique, to define the stress at which plastic deformation begins, providing a practical standard for engineering applications.

Factors Affecting Elastic Limit and Yield Strength

Elastic limit and yield strength are influenced by material composition, temperature, and strain rate, affecting their mechanical behavior. Microstructural factors such as grain size, dislocation density, and alloying elements alter atomic bonding strength, directly impacting these properties. Heat treatment processes, including annealing and quenching, modify internal stresses and defect structures, resulting in variation in both elastic limit and yield strength.

Elastic Limit vs Yield Strength in Different Materials

Elastic limit and yield strength represent critical thresholds in material deformation, with the elastic limit marking the maximum stress a material can endure without permanent deformation, while the yield strength indicates the stress at which noticeable plastic deformation begins. In metals like steel and aluminum, the yield strength is often closely aligned with the elastic limit, making these parameters nearly interchangeable. However, polymers and composites may exhibit significant differences between their elastic limit and yield strength due to their viscoelastic behavior and complex microstructures, affecting their stress-strain responses under load.

Practical Applications in Engineering and Design

Elastic limit defines the maximum stress a material can endure without permanent deformation, critical for ensuring structural components return to their original shape under operational loads. Yield strength indicates the stress at which a material begins to deform plastically, serving as a threshold for safe load-bearing capacity in engineering design. Understanding both properties enables engineers to select materials and design components that withstand real-world conditions while avoiding structural failure and excessive maintenance.

Summary and Conclusion

Elastic limit defines the maximum stress a material can withstand without permanent deformation, while yield strength indicates the stress level at which a material begins to deform plastically. The elastic limit is always lower or equal to the yield strength, marking the boundary for reversible behavior, whereas yield strength signifies the onset of permanent structural change. Understanding both properties is essential for designing materials that avoid irreversible deformation under operational stresses.

Elastic limit Infographic

libterm.com

libterm.com