Gas cycle refrigeration uses compressed gas to absorb heat and provide cooling without relying on traditional refrigerants, making it an eco-friendly option. This system operates by compressing a gas, removing the heat through a heat exchanger, and then expanding the gas to create a cooling effect. Discover the key components and benefits of gas cycle refrigeration as you read on.

Table of Comparison

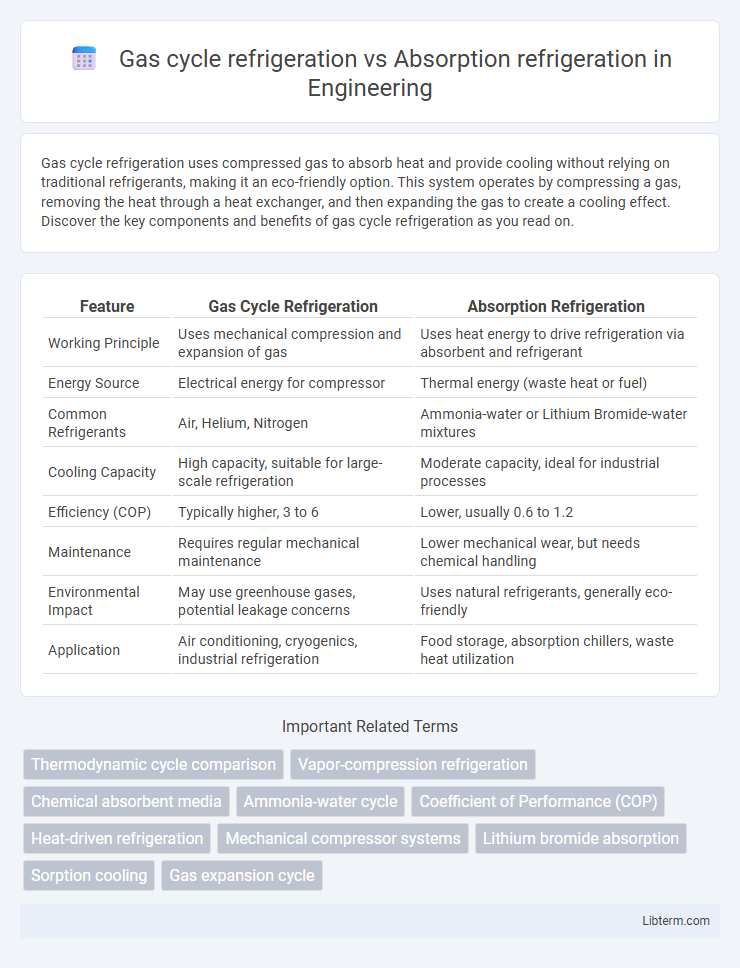

| Feature | Gas Cycle Refrigeration | Absorption Refrigeration |

|---|---|---|

| Working Principle | Uses mechanical compression and expansion of gas | Uses heat energy to drive refrigeration via absorbent and refrigerant |

| Energy Source | Electrical energy for compressor | Thermal energy (waste heat or fuel) |

| Common Refrigerants | Air, Helium, Nitrogen | Ammonia-water or Lithium Bromide-water mixtures |

| Cooling Capacity | High capacity, suitable for large-scale refrigeration | Moderate capacity, ideal for industrial processes |

| Efficiency (COP) | Typically higher, 3 to 6 | Lower, usually 0.6 to 1.2 |

| Maintenance | Requires regular mechanical maintenance | Lower mechanical wear, but needs chemical handling |

| Environmental Impact | May use greenhouse gases, potential leakage concerns | Uses natural refrigerants, generally eco-friendly |

| Application | Air conditioning, cryogenics, industrial refrigeration | Food storage, absorption chillers, waste heat utilization |

Introduction to Refrigeration Systems

Gas cycle refrigeration systems operate based on the compression and expansion of a refrigerant gas to absorb and reject heat, commonly used in applications requiring rapid cooling and moderate efficiency. Absorption refrigeration systems utilize a heat source to drive the refrigeration process through the absorption of refrigerant by an absorbent, typically employing ammonia-water or lithium bromide-water mixtures for energy-efficient, low-electricity environments. Both systems serve critical roles in refrigeration technology, with gas cycles suited for mechanical-based cooling and absorption systems preferred in waste heat recovery and solar cooling applications.

Overview of Gas Cycle Refrigeration

Gas cycle refrigeration operates by compressing a gas, cooling it through heat rejection, and then expanding it to produce a cooling effect, commonly using air or other gases as the working fluid. This system is typically employed in applications requiring low-temperature refrigeration without the use of harmful refrigerants, benefiting from mechanical simplicity and environmental sustainability. Key components include a compressor, heat exchangers, an expander, and a cooler, which together facilitate the thermodynamic cycle essential for energy-efficient cooling.

Basics of Absorption Refrigeration

Absorption refrigeration operates on a heat-driven cycle using a refrigerant and absorbent pair, typically ammonia and water or lithium bromide and water, where the refrigerant evaporates at low pressure to absorb heat and is subsequently absorbed by the absorbent. This process eliminates the need for mechanical compressors found in gas cycle refrigeration, relying instead on thermal energy to regenerate the refrigerant through heating in the generator. The system consists of key components such as evaporator, absorber, generator, and condenser, optimizing energy efficiency in applications using waste heat or solar energy.

Key Components of Both Systems

Gas cycle refrigeration relies primarily on a compressor, expander, and heat exchangers to compress and expand refrigerant gases like air or ammonia, facilitating cooling through gas expansion and heat transfer. Absorption refrigeration systems use a solution pump, absorber, generator, condenser, and evaporator, with refrigerants such as water-ammonia or lithium bromide-water mixtures exploiting the absorption and desorption processes driven by heat energy. The fundamental difference lies in the gas cycle's mechanical work to circulate refrigerants, whereas absorption systems utilize thermal energy for continuous refrigeration without a mechanical compressor.

Working Principles: Gas Cycle vs Absorption

Gas cycle refrigeration operates by compressing and expanding a refrigerant gas, utilizing its thermodynamic properties to absorb and reject heat during the cycle. Absorption refrigeration relies on a heat-driven process where a refrigerant is absorbed by a liquid absorbent, separated by heating, and then condensed and evaporated to provide cooling. The gas cycle depends on mechanical energy input for compression, while absorption refrigeration primarily uses thermal energy, often waste heat or solar energy, making it suitable for environments lacking electrical power.

Energy Efficiency Comparison

Gas cycle refrigeration systems typically achieve higher energy efficiency with COP (Coefficient of Performance) values ranging from 0.3 to 0.6, utilizing mechanical compression driven by gas engines or turbines. Absorption refrigeration, employing heat-driven cycles with refrigerants like ammonia-water or lithium bromide-water, generally exhibits lower COP values between 0.4 and 0.7 but benefits from waste heat or solar thermal energy input, reducing electrical energy demand. Energy efficiency comparison highlights that while gas cycle units deliver better performance under electrical power sources, absorption systems excel in applications leveraging low-grade heat, improving overall system sustainability despite lower instantaneous efficiency.

Environmental Impact Analysis

Gas cycle refrigeration systems typically rely on vapor compression using hydrofluorocarbon (HFC) refrigerants, which have high global warming potential (GWP) and contribute significantly to greenhouse gas emissions. Absorption refrigeration uses water-ammonia or lithium bromide solutions as refrigerants, resulting in lower direct emissions and better compatibility with renewable heat sources, reducing overall environmental impact. Energy efficiency in absorption systems tends to be lower than gas cycle systems, but their use of waste heat or solar energy minimizes fossil fuel consumption and carbon footprint.

Cost Considerations

Gas cycle refrigeration systems generally have higher initial investment costs due to complex components like gas turbines or compressors, but they offer lower operating expenses with efficient energy use in large-scale applications. Absorption refrigeration typically incurs lower upfront costs by utilizing inexpensive heat sources such as waste heat or solar energy, yet it experiences higher operational costs because of lower coefficient of performance (COP) and the need for continuous heat input. Cost considerations also include maintenance expenses, where gas cycle systems demand more frequent servicing due to mechanical complexity, while absorption systems benefit from simpler mechanical design but potential issues related to the absorbent solution.

Typical Applications and Industries

Gas cycle refrigeration is commonly utilized in aerospace and automotive industries for cooling turbine engines and HVAC systems due to its efficiency at high power outputs and ability to operate under varying atmospheric conditions. Absorption refrigeration finds typical applications in industries such as food processing, pharmaceuticals, and large-scale commercial buildings where waste heat recovery and energy efficiency are prioritized, often using natural refrigerants like ammonia or water-lithium bromide solutions. Both systems serve critical roles in industrial processes, with gas cycle refrigeration favored for dynamic mechanical environments and absorption refrigeration preferred for sustainable, low-electricity settings.

Pros and Cons of Each Refrigeration Method

Gas cycle refrigeration offers high efficiency and rapid cooling with environmentally friendly refrigerants, but involves complex components and higher operational costs. Absorption refrigeration excels in utilizing waste heat or renewable energy sources, boasts low electricity consumption, and operates quietly, yet generally delivers lower cooling capacity and requires a heat source for effective performance. Selecting between these methods depends on factors like energy availability, environmental considerations, and application-specific cooling demands.

Gas cycle refrigeration Infographic

libterm.com

libterm.com