Maximum displacement refers to the greatest distance an object moves from its equilibrium or rest position during oscillation or vibration. It is a key parameter in physics and engineering, indicating the amplitude of motion and helping assess system behavior under dynamic conditions. Discover more insights and practical applications of maximum displacement in the following article.

Table of Comparison

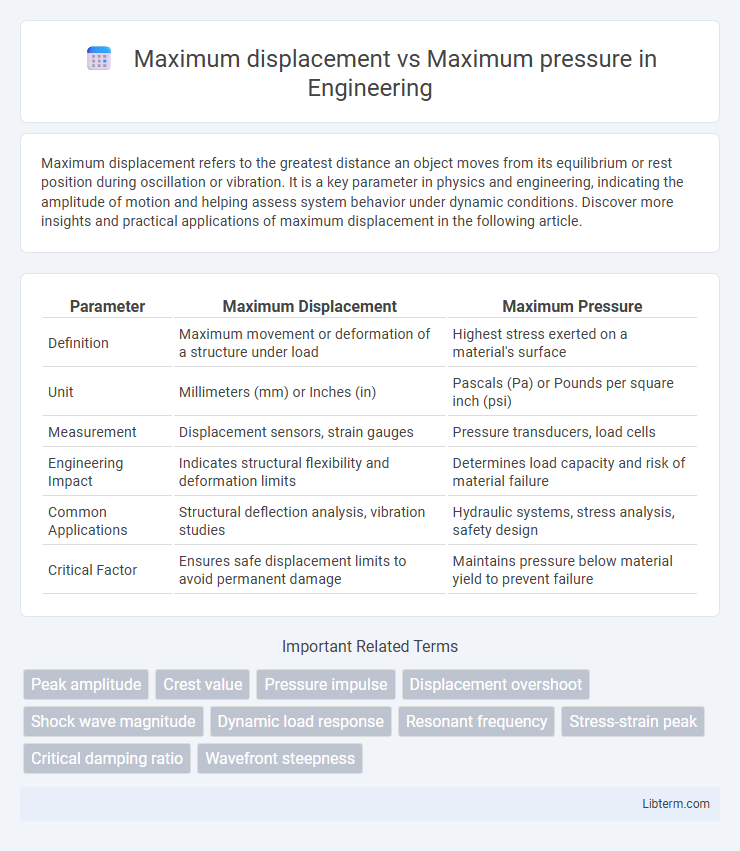

| Parameter | Maximum Displacement | Maximum Pressure |

|---|---|---|

| Definition | Maximum movement or deformation of a structure under load | Highest stress exerted on a material's surface |

| Unit | Millimeters (mm) or Inches (in) | Pascals (Pa) or Pounds per square inch (psi) |

| Measurement | Displacement sensors, strain gauges | Pressure transducers, load cells |

| Engineering Impact | Indicates structural flexibility and deformation limits | Determines load capacity and risk of material failure |

| Common Applications | Structural deflection analysis, vibration studies | Hydraulic systems, stress analysis, safety design |

| Critical Factor | Ensures safe displacement limits to avoid permanent damage | Maintains pressure below material yield to prevent failure |

Understanding Maximum Displacement and Maximum Pressure

Maximum displacement refers to the greatest extent a structure or material moves from its original position under a given load, serving as a critical parameter in mechanical and structural engineering to assess flexibility and deformation limits. Maximum pressure denotes the highest force exerted per unit area within a system, vital for evaluating stress distribution and ensuring material integrity under load conditions. Understanding the relationship between maximum displacement and maximum pressure allows engineers to predict performance, prevent failure, and optimize design by balancing deformation capacity with pressure resistance.

Key Differences Between Displacement and Pressure

Maximum displacement measures the greatest distance an object moves from its original position, typically expressed in units like millimeters or inches, while maximum pressure quantifies the highest force exerted per unit area, measured in pascals or psi. Displacement reflects the physical movement or deformation of a material or structure, whereas pressure indicates the intensity of force applied over a surface. Understanding these differences is crucial in fields such as mechanical engineering and fluid dynamics, where displacement relates to structural response and pressure pertains to force distribution.

The Physics Behind Displacement and Pressure

Maximum displacement in a mechanical system refers to the greatest extent an object moves from its equilibrium position, driven by forces acting upon it, while maximum pressure is the highest force exerted per unit area within a fluid or solid. The physics behind displacement involves concepts of elasticity, inertia, and applied force, where Hooke's Law often relates displacement to the restoring force, whereas pressure stems from the microscopic collisions of particles or macroscopic force distribution over areas. Understanding the interplay between these quantities is essential in designing structures and devices to withstand stress and avoid failure under varying loads.

Factors Influencing Maximum Displacement

Factors influencing maximum displacement include material properties such as elasticity and density, geometric parameters like thickness and shape, and applied load characteristics including magnitude and distribution. Boundary conditions and support constraints also significantly affect the extent of displacement under pressure. Understanding these variables is essential for optimizing structural performance and preventing failure due to excessive deformation.

Factors Affecting Maximum Pressure

Maximum pressure in a system is primarily influenced by factors such as material properties, geometry, and operational conditions, which also indirectly affect maximum displacement. Material strength and elasticity determine how much pressure a component can withstand before deforming, while geometric features like thickness and shape influence stress distribution and pressure limits. Operational variables including temperature, loading rate, and environmental exposure further impact maximum pressure by altering material behavior and system constraints.

Practical Applications: Displacement vs Pressure

Maximum displacement and maximum pressure are critical parameters in fluid power systems, where displacement refers to the volume of fluid moved by a pump or actuator, directly affecting system flow rate and speed. Maximum pressure determines the force output and system capacity to perform work, influencing safety and durability in hydraulic circuits. Practical applications balance displacement and pressure to optimize performance, such as selecting pumps for industrial machinery requiring precise motion control or designing hydraulic brakes where pressure limits prevent component failure.

Measurement Techniques for Displacement and Pressure

Precise measurement techniques for maximum displacement commonly involve laser displacement sensors and capacitive sensors, providing high-resolution data critical for structural and mechanical assessments. For maximum pressure, piezoelectric sensors and strain gauge-based transducers offer accurate real-time pressure readings essential in hydraulic and pneumatic systems. Integrating these measurement methods enables detailed analysis of material behavior under varying stress conditions, enhancing predictive maintenance and engineering design accuracy.

Impact of Maximum Displacement on System Performance

Maximum displacement in mechanical systems directly influences the stress distribution and load-bearing capacity, often causing variations in maximum pressure experienced by components. Increased displacement can lead to higher deformation, affecting seals and joints, which may compromise system integrity and reduce operational efficiency. Accurate control of displacement is critical to maintaining optimal pressure levels and ensuring reliable performance under dynamic loads.

Consequences of Exceeding Maximum Pressure

Exceeding maximum pressure in mechanical systems causes a sharp increase in maximum displacement, leading to permanent deformation or structural failure. When pressure surpasses design limits, materials may yield or fracture, compromising safety and functionality. Accurate monitoring of maximum pressure is essential to prevent excessive displacement and costly damage.

Comparing Maximum Displacement and Pressure in Engineering Systems

Maximum displacement in engineering systems refers to the greatest movement or deformation experienced by a component under load, often measured in millimeters or inches. Maximum pressure, typically expressed in Pascals or psi, indicates the highest stress exerted on a surface within the system. Comparing these two parameters is critical for system design, as excessive displacement can lead to mechanical failure or misalignment, while high pressure may cause structural damage or material fatigue.

Maximum displacement Infographic

libterm.com

libterm.com