Tunnel form construction is a fast and efficient method combining formwork and concrete casting to create repetitive, uniform structures like residential blocks and hotels. This system significantly reduces construction time and labor costs by enabling continuous, swift forming and curing cycles. Discover how tunnel form technology can streamline your building project by reading the rest of the article.

Table of Comparison

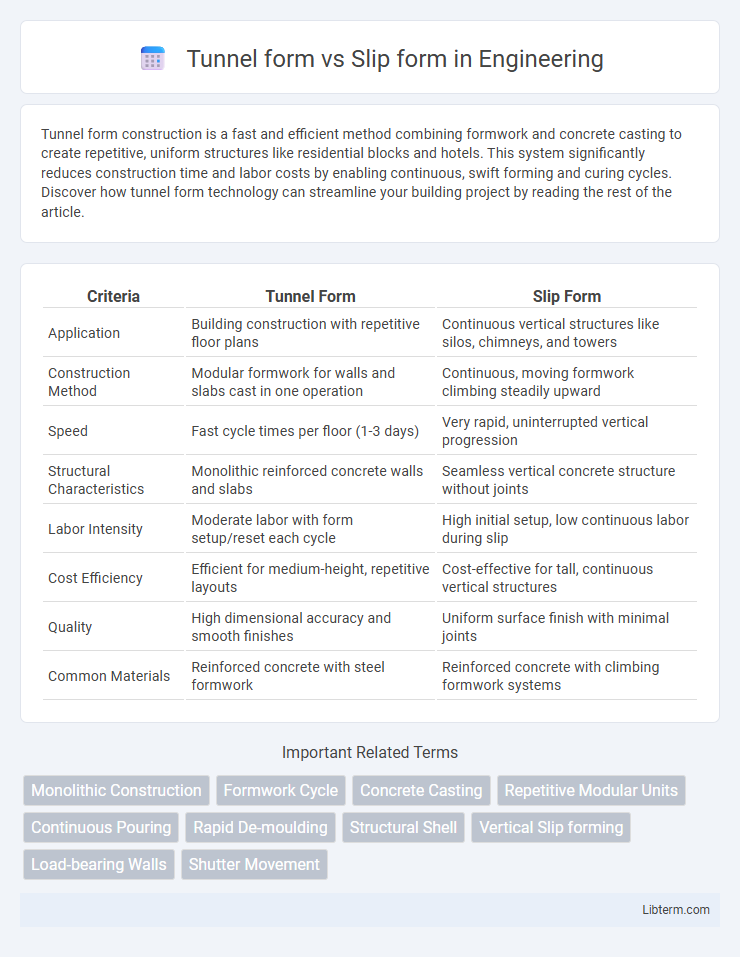

| Criteria | Tunnel Form | Slip Form |

|---|---|---|

| Application | Building construction with repetitive floor plans | Continuous vertical structures like silos, chimneys, and towers |

| Construction Method | Modular formwork for walls and slabs cast in one operation | Continuous, moving formwork climbing steadily upward |

| Speed | Fast cycle times per floor (1-3 days) | Very rapid, uninterrupted vertical progression |

| Structural Characteristics | Monolithic reinforced concrete walls and slabs | Seamless vertical concrete structure without joints |

| Labor Intensity | Moderate labor with form setup/reset each cycle | High initial setup, low continuous labor during slip |

| Cost Efficiency | Efficient for medium-height, repetitive layouts | Cost-effective for tall, continuous vertical structures |

| Quality | High dimensional accuracy and smooth finishes | Uniform surface finish with minimal joints |

| Common Materials | Reinforced concrete with steel formwork | Reinforced concrete with climbing formwork systems |

Introduction to Tunnel Form and Slip Form

Tunnel form construction involves casting concrete in a repetitive, modular system using large, reusable steel forms that create both walls and slabs simultaneously, enhancing speed and structural integrity in high-rise buildings. Slip form technology utilizes a continuous, upward-moving formwork, allowing seamless pouring of concrete for vertical structures like silos and towers, which improves efficiency and uniformity. Both methods optimize construction timelines but differ significantly in formwork movement and application scope.

Overview of Tunnel Form Construction

Tunnel form construction involves using large, reusable steel or aluminum forms to cast walls and slabs simultaneously, enabling rapid and repetitive building cycles primarily in residential and commercial projects. This method enhances structural uniformity, reduces labor costs, and shortens construction time compared to traditional techniques. Slip form construction differs by continuously pouring concrete into moving forms, primarily used for vertical structures like silos or towers, whereas tunnel form focuses on modular, tunnel-shaped units promoting efficient mass housing production.

Overview of Slip Form Construction

Slip form construction is a continuous concrete pouring method used primarily for tall structures such as silos, chimneys, and towers, enabling efficient vertical progress without joints. The slip form moves upward steadily as concrete is placed and initially sets, allowing seamless, uniform walls with high structural integrity. This technique offers speed advantages and superior surface quality compared to traditional tunnel form construction, which relies on fixed forms cast in sections.

Key Differences Between Tunnel Form and Slip Form

Tunnel form construction uses reusable steel forms to cast entire walls and slabs in a single concrete pour, ensuring rapid cycle times and uniform wall thickness. Slip form involves continuously climbing formwork that allows for uninterrupted concrete pouring, ideal for tall vertical structures like silos or towers. Key differences include tunnel form's emphasis on repetitive, modular residential units, while slip form specializes in seamless vertical construction with variable heights.

Structural Applications of Tunnel Form

Tunnel form construction excels in creating repetitive, high-strength concrete walls and slabs ideal for residential buildings, hotels, and institutional structures requiring rapid cycle times and high durability. Its formwork system integrates walls and floor slabs in a single pour, enhancing structural integrity and reducing joint weaknesses compared to slip form, which is primarily used for vertical elements like silos, chimneys, and tall core walls. Tunnel form offers superior seismic performance and dimensional accuracy, making it preferred for projects demanding robust load-bearing capacity and uniform load distribution.

Structural Applications of Slip Form

Slip form construction excels in creating continuous, monolithic concrete structures such as tall towers, silos, and vertical shafts due to its ability to pour concrete rapidly while maintaining uniformity and strength. This method is ideal for structures requiring high structural integrity and rapid vertical progression, allowing for seamless walls without joints or cold seams. Slip form's adaptability in shaping complex geometries and producing consistent quality makes it preferred over tunnel form in applications demanding uninterrupted vertical elements.

Advantages of Tunnel Form Method

The Tunnel Form method offers significant advantages such as faster construction speed due to its repetitive and modular formwork system, enabling simultaneous casting of walls and slabs. This approach enhances structural strength and uniformity, resulting in high-quality finishes with reduced labor costs. Its adaptability to various building designs and improved safety on-site further make it an efficient choice in large-scale residential and commercial projects.

Advantages of Slip Form Method

The Slip Form Method offers continuous, rapid construction, enhancing efficiency and reducing project timelines compared to the Tunnel Form Method. It enables seamless vertical structures with superior surface finish and minimal joint lines, improving structural integrity and aesthetic appeal. This technique also allows greater flexibility in height adjustments and complex shapes, optimizing material usage and labor costs.

Limitations and Challenges of Each Method

Tunnel form construction faces limitations in design flexibility due to its reliance on repetitive, modular layouts, making it less suitable for complex architectural shapes. Slip form challenges include maintaining continuous, uninterrupted concrete pouring, which requires skilled labor and precise coordination to avoid structural defects. Both methods demand significant upfront planning and specialized equipment, potentially increasing project costs and timelines for customized or irregular building designs.

Choosing the Right Method: Factors to Consider

Choosing between tunnel form and slip form methods depends on project scale, timeline, and structural design requirements. Tunnel form offers rapid construction and high-quality finish for repetitive layouts like residential or hotel buildings, while slip form suits continuous vertical structures such as silos or high-rise cores. Site constraints, labor skills, and material availability also influence the optimal formwork technique for efficient and cost-effective construction.

Tunnel form Infographic

libterm.com

libterm.com