Knoop hardness testing measures the microhardness of materials using an elongated diamond indenter under a specific load, providing precise surface hardness values ideal for thin materials or coatings. This technique is crucial in quality control and material research to assess the mechanical properties of small or delicate samples. Explore the rest of the article to understand how Knoop hardness testing can improve your material analysis processes.

Table of Comparison

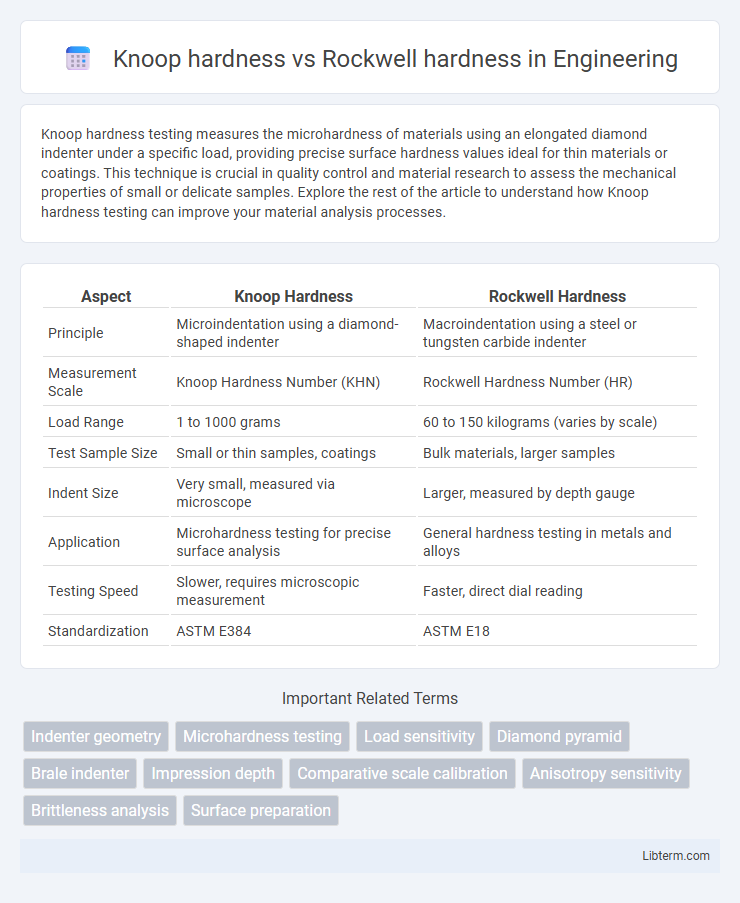

| Aspect | Knoop Hardness | Rockwell Hardness |

|---|---|---|

| Principle | Microindentation using a diamond-shaped indenter | Macroindentation using a steel or tungsten carbide indenter |

| Measurement Scale | Knoop Hardness Number (KHN) | Rockwell Hardness Number (HR) |

| Load Range | 1 to 1000 grams | 60 to 150 kilograms (varies by scale) |

| Test Sample Size | Small or thin samples, coatings | Bulk materials, larger samples |

| Indent Size | Very small, measured via microscope | Larger, measured by depth gauge |

| Application | Microhardness testing for precise surface analysis | General hardness testing in metals and alloys |

| Testing Speed | Slower, requires microscopic measurement | Faster, direct dial reading |

| Standardization | ASTM E384 | ASTM E18 |

Introduction to Hardness Testing Methods

Knoop hardness and Rockwell hardness are two distinct methods used to measure the hardness of materials, each suited for different applications. Knoop hardness testing employs a diamond indenter with an elongated pyramidal shape, ideal for measuring microhardness on thin materials or small parts by producing a shallow, precise indentation. Rockwell hardness testing uses various steel or tungsten carbide indenters to measure macrohardness rapidly by determining the depth of penetration under a specific load, commonly applied in quality control and bulk material testing.

Overview of Knoop Hardness Test

The Knoop hardness test measures microhardness by indenting a material's surface with an elongated diamond tip under a specific load, suitable for thin materials or coatings. It provides detailed insights into surface hardness variations at microscopic scales, making it ideal for brittle materials and small samples where Rockwell hardness testing may be impractical. Unlike the Rockwell test, which uses a larger, conical or spherical indenter and measures depth of penetration, the Knoop method emphasizes precision in evaluating thin films and surface layers with minimal damage.

Overview of Rockwell Hardness Test

The Rockwell hardness test measures the depth of penetration of an indenter under a fixed load, providing a direct hardness number without requiring optical measurement. It uses different scales (e.g., A, B, C) depending on the material and indenter type, making it versatile for testing metals and alloys. This method is faster and more widely used in industrial applications compared to the Knoop hardness test, which is better suited for microhardness evaluation of small or thin specimens.

Principle Differences Between Knoop and Rockwell Hardness

The Knoop hardness test uses a diamond indenter with an elongated pyramidal shape to measure hardness by evaluating the length of the indentation under a low load, ideal for thin materials and coatings. In contrast, the Rockwell hardness test employs a conical or spherical indenter, measuring hardness based on the depth of penetration under a higher load, suitable for bulk materials and metals. The Knoop test provides high precision on micro-scale hardness with minimal damage, while Rockwell hardness offers quicker results for general hardness assessment with standardized scales.

Applications of Knoop Hardness Testing

Knoop hardness testing is predominantly used in applications requiring precise measurement of microhardness on thin materials, small parts, and coatings, such as in semiconductor wafers, thin films, and dental enamel. Its elongated indenter produces shallow, finely detailed impressions ideal for assessing surface properties without damaging delicate structures. This method is preferred over Rockwell hardness testing when evaluating thin layers or microscale components that cannot withstand the heavier loads applied in Rockwell testing.

Applications of Rockwell Hardness Testing

Rockwell hardness testing is widely applied in quality control for manufacturing steel, aluminum, and other alloys due to its rapid and non-destructive measurement process. It is preferred in automotive, aerospace, and construction industries where assessing the material's resistance to deformation and wear is critical for component performance and durability. Rockwell hardness values guide heat treatment processes, ensuring materials meet specific hardness requirements for their intended applications.

Material Suitability: Knoop vs Rockwell Hardness

Knoop hardness testing is ideal for measuring very thin materials, coatings, and small parts due to its microindentation capability with minimal surface damage. Rockwell hardness testing suits bulk materials and thicker metals, providing rapid and straightforward hardness values with larger indentations. Industries requiring precise surface hardness evaluation, such as microelectronics or thin films, favor Knoop, while automotive and heavy manufacturing often rely on Rockwell hardness for overall material assessment.

Advantages and Limitations of Knoop Hardness

Knoop hardness testing offers high precision for measuring very thin materials or small volumes, making it ideal for microhardness applications in coatings, thin films, and small parts. Its shallow indentation minimizes damage and allows for hardness measurement on brittle materials and thin layers without cracking or substrate interference. However, the Knoop method requires careful preparation, is more time-consuming, and has less straightforward correlation with bulk mechanical properties compared to Rockwell hardness, which provides quicker, more standardized testing for larger, homogeneous samples.

Advantages and Limitations of Rockwell Hardness

Rockwell hardness testing offers rapid, direct readings without requiring extensive sample preparation, making it highly efficient for quality control in manufacturing settings. However, its limitations include lower sensitivity to surface irregularities and less accuracy on very thin or small specimens compared to Knoop hardness, which uses a microscopic indentation suitable for thin films and microstructures. Rockwell tests are better suited for bulk materials but may not provide precise hardness values for thin coatings or small-scale features.

Choosing Between Knoop and Rockwell Hardness Methods

Knoop hardness testing is ideal for measuring thin materials and small, precise areas due to its microindentation method, while Rockwell hardness testing suits bulk materials and offers faster results with larger indentation methods. Selecting between Knoop and Rockwell hardness depends on factors such as sample thickness, surface finish, and the required precision level. Industries dealing with thin films, coatings, and microelectronics typically prefer Knoop hardness, whereas automotive and metals manufacturing favor Rockwell hardness for its efficiency and simplicity.

Knoop hardness Infographic

libterm.com

libterm.com