A linear encoder is a precision sensor used to measure position or displacement along a straight path with high accuracy. This device converts motion into electrical signals, enabling precise control and feedback in applications such as CNC machines, robotics, and industrial automation. Discover how a linear encoder can enhance your systems by reading the full article.

Table of Comparison

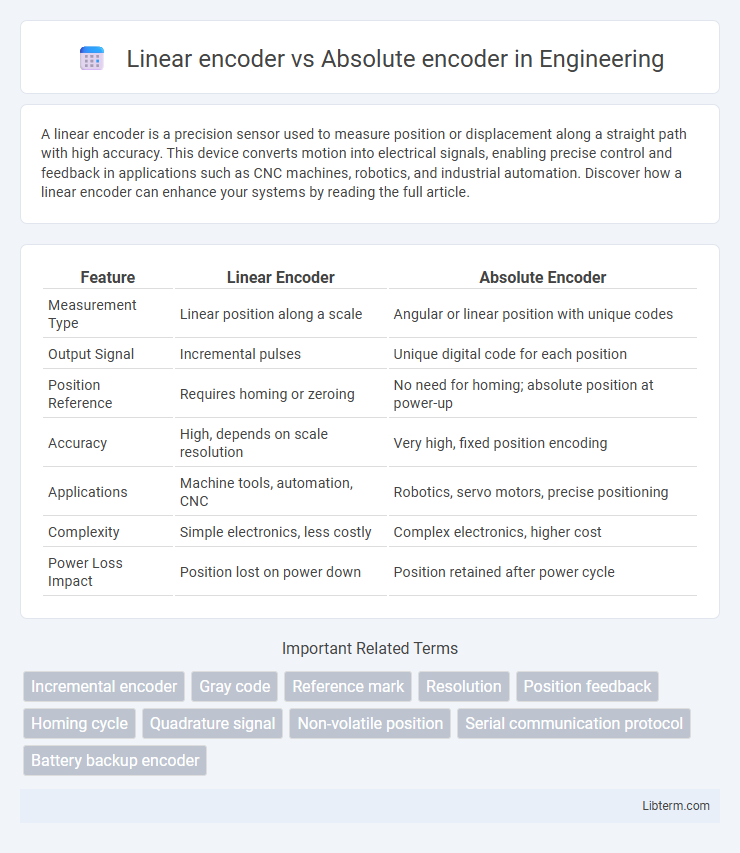

| Feature | Linear Encoder | Absolute Encoder |

|---|---|---|

| Measurement Type | Linear position along a scale | Angular or linear position with unique codes |

| Output Signal | Incremental pulses | Unique digital code for each position |

| Position Reference | Requires homing or zeroing | No need for homing; absolute position at power-up |

| Accuracy | High, depends on scale resolution | Very high, fixed position encoding |

| Applications | Machine tools, automation, CNC | Robotics, servo motors, precise positioning |

| Complexity | Simple electronics, less costly | Complex electronics, higher cost |

| Power Loss Impact | Position lost on power down | Position retained after power cycle |

Introduction to Linear and Absolute Encoders

Linear encoders measure position along a straight path, converting mechanical motion into digital signals with high precision ideal for CNC machines and automation systems. Absolute encoders provide unique position values at every point, ensuring reliable data retention even during power loss, crucial for robotics and industrial equipment requiring exact positional feedback. Both encoders play vital roles in motion control, with linear encoders focused on distance measurement and absolute encoders on positional accuracy and continuity.

How Linear Encoders Work

Linear encoders work by converting the position of a moving object along a linear path into an electronic signal, which is then interpreted by a control system to determine precise position or displacement. They typically use a scale with finely spaced graduations and a readhead that detects changes through optical, magnetic, or inductive sensing methods to generate incremental or absolute position data. Optical linear encoders employ light interruption or reflection to produce high-resolution position feedback, while magnetic linear encoders use changes in magnetic fields for robust measurements in harsh environments.

How Absolute Encoders Operate

Absolute encoders operate by providing a unique digital code for each shaft position, ensuring precise and unambiguous position identification even after power loss. They use coded disc patterns or magnetic sensors to generate absolute position data, eliminating the need for homing procedures during startup. This direct measurement capability contrasts with linear encoders that measure displacement relative to a reference point, making absolute encoders essential for applications requiring immediate and reliable position feedback.

Key Differences Between Linear and Absolute Encoders

Linear encoders measure position by detecting linear displacement along a specified path, converting physical movement into electronic signals, while absolute encoders provide a unique digital code for each position, ensuring precise and unambiguous location data. Linear encoders often require external referencing or homing to determine an absolute position after power loss, whereas absolute encoders retain position information immediately upon startup without needing recalibration. The key difference lies in data output and reliability: linear encoders output relative position data subject to cumulative errors, while absolute encoders deliver unique, error-resistant position values critical in applications requiring high accuracy and immediate position recognition.

Accuracy and Resolution Comparison

Linear encoders provide high resolution by measuring incremental position changes with accuracy influenced by scale graduations and interpolation capabilities. Absolute encoders offer precise positional data through unique code patterns for each position, ensuring accurate readings even after power loss, with resolution dependent on code disk design and sensor quality. In applications demanding continuous position tracking and power-off reliability, absolute encoders often deliver superior accuracy, while linear encoders excel in high-resolution incremental measurements.

Application Areas: Linear vs. Absolute Encoders

Linear encoders excel in applications requiring precise measurement of position or displacement along a single axis, commonly used in CNC machines, semiconductor manufacturing, and precision metalworking. Absolute encoders provide unique position values at every point of rotation or linear travel, making them ideal for robotics, automated assembly lines, and safety-critical systems where power loss or position referencing must be avoided. Both encoder types serve critical roles in industrial automation, with linear encoders favoring high-resolution length measurement and absolute encoders ensuring reliable, non-ambiguous position feedback.

Installation and Maintenance Considerations

Installation of linear encoders typically requires precise alignment along the measurement axis to ensure accurate readings, while absolute encoders often demand careful mounting to maintain correct positional referencing. Maintenance for linear encoders involves regular cleaning to prevent debris from affecting the scale readhead, whereas absolute encoders generally require less frequent calibration due to their inherent position retention. Choosing between the two depends on the application's tolerance for downtime and environmental conditions impacting encoder longevity.

Cost Analysis: Linear vs. Absolute Encoders

Linear encoders generally offer lower initial costs compared to absolute encoders due to their simpler design and fewer components. Absolute encoders tend to be more expensive because they provide unique position values at power-up, eliminating the need for homing procedures and reducing downtime in critical applications. Maintenance costs for absolute encoders can be lower over time, as their enhanced reliability and precision reduce errors and recalibration needs.

Advantages and Disadvantages of Each Encoder Type

Linear encoders provide high-resolution position feedback and are ideal for applications requiring precise measurement over a linear path, offering simple installation and cost-effective operation. Absolute encoders deliver unique position values upon startup without needing a reference, enhancing reliability in power-loss scenarios and reducing the risk of position errors. However, linear encoders may lose position data during power interruptions and require recalibration, whereas absolute encoders are generally more complex and expensive due to their integrated position coding systems.

Choosing the Right Encoder for Your Needs

Selecting the right encoder depends on the application requirements for position accuracy and system complexity. Linear encoders provide precise incremental position feedback suited for high-resolution measurements and are ideal for applications needing relative movement tracking. Absolute encoders deliver unique position data for each shaft angle or linear position, eliminating the need for homing and ensuring reliable data retention during power loss, making them suitable for systems requiring absolute position awareness.

Linear encoder Infographic

libterm.com

libterm.com