Effective instruction lists enhance task clarity and improve productivity by providing step-by-step guidance tailored to your specific needs. Clear, concise commands reduce errors and help maintain focus, ensuring successful completion of even complex processes. Explore the rest of this article to discover tips for creating optimized instruction lists that empower you to achieve your goals efficiently.

Table of Comparison

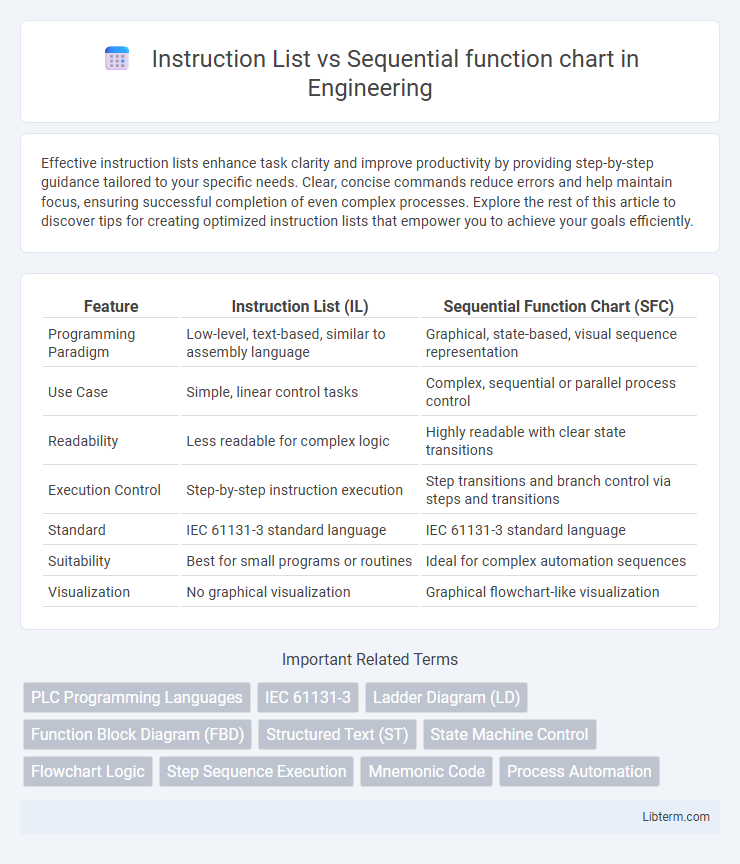

| Feature | Instruction List (IL) | Sequential Function Chart (SFC) |

|---|---|---|

| Programming Paradigm | Low-level, text-based, similar to assembly language | Graphical, state-based, visual sequence representation |

| Use Case | Simple, linear control tasks | Complex, sequential or parallel process control |

| Readability | Less readable for complex logic | Highly readable with clear state transitions |

| Execution Control | Step-by-step instruction execution | Step transitions and branch control via steps and transitions |

| Standard | IEC 61131-3 standard language | IEC 61131-3 standard language |

| Suitability | Best for small programs or routines | Ideal for complex automation sequences |

| Visualization | No graphical visualization | Graphical flowchart-like visualization |

Overview of Instruction List and Sequential Function Chart

Instruction List (IL) is a low-level programming language resembling assembly, designed for simple and efficient control logic representation in programmable logic controllers (PLCs). Sequential Function Chart (SFC) provides a graphical method of programming, illustrating control processes through steps, transitions, and actions to enhance clarity and structured sequencing. IL emphasizes textual coding efficiency, while SFC supports visual process flow management for complex automation sequences.

Key Differences Between Instruction List and Sequential Function Chart

Instruction List (IL) is a low-level programming language resembling assembly language, emphasizing detailed control with instructions executed sequentially, while Sequential Function Chart (SFC) provides a graphical representation of process steps and transitions, enhancing visualization of control flow in automation tasks. IL uses a linear sequence of simple instructions for direct hardware manipulation, making it efficient for repetitive, time-critical operations. In contrast, SFC organizes the process into steps and actions linked by transitions, enabling modular programming and easier troubleshooting in complex control systems.

Structure and Syntax of Instruction List

Instruction List (IL) features a low-level, assembly-like syntax using mnemonics for operations, registers, and operands structured in sequential lines, facilitating precise control flow with jump instructions. Sequential Function Chart (SFC) employs a graphical, state-oriented structure with steps, transitions, and actions defining process sequences visually, emphasizing modular and parallel task execution. IL syntax prioritizes concise command sequences ideal for detailed machine-level logic, contrasting with SFC's hierarchical, easy-to-interpret graphical representation for complex process flows.

Structure and Visualization of Sequential Function Chart

Instruction List (IL) utilizes a low-level, textual programming structure resembling assembly language, focusing on concise command sequences for precise control. Sequential Function Chart (SFC) offers a graphical, block-structured visualization that represents the control flow through steps and transitions, enhancing clarity in complex automation processes. SFC's modular design facilitates easier debugging and maintenance by visually depicting execution sequences and parallel operations within industrial control systems.

Advantages of Instruction List Programming

Instruction List programming offers a compact and efficient coding style ideal for low-level hardware control and simple repetitive tasks. Its text-based format allows for easy editing and minimal memory usage compared to Sequential Function Chart, which is more graphical and better suited for complex process visualization. Instruction List enhances precise timing and resource optimization in embedded systems, making it advantageous for developers prioritizing speed and control.

Benefits of Using Sequential Function Chart

Sequential Function Chart (SFC) offers clear visualization of process sequences and states, improving the understanding and debugging of complex automation tasks. It enables modular programming with defined steps and transitions, enhancing maintainability and scalability compared to Instruction List (IL). SFC's graphical nature simplifies the design of parallel processes and conditional branching, leading to more efficient control system development.

Use Cases and Industry Applications

Instruction List (IL) is widely used in low-level control tasks requiring precise timing and resource optimization, such as in embedded systems and simple automation devices. Sequential Function Chart (SFC) is preferred for complex process control and batch management in industries like manufacturing, chemical processing, and automotive, enabling clear visualization of operational sequences. Both IEC 61131-3 programming languages complement each other, with IL suited for efficient code execution and SFC enhancing process clarity and maintainability.

Programming Efficiency and Readability Comparison

Instruction List (IL) offers compact code ideal for low-level hardware control, enhancing programming efficiency through concise syntax, but it can be harder to read due to its assembly-like structure. Sequential Function Chart (SFC) emphasizes graphical representation with clear step transitions, improving readability and easier debugging, although it may require more code and time to design complex processes. Choosing between IL and SFC depends on the balance needed between fast coding and intuitive visualization in automation projects.

Debugging and Maintenance Considerations

Instruction List (IL) offers straightforward linear code execution, making debugging simpler through step-by-step code inspection and clear variable states. Sequential Function Chart (SFC) provides a graphical overview of control flow, aiding maintenance by visualizing process steps and transitions, which simplifies identifying logical errors and system state at any point. While IL's text-based format facilitates quick code edits, SFC's modular structure supports easier modifications and scalability during system updates.

Choosing the Right Approach for Your PLC Projects

Instruction List (IL) offers low-level programming ideal for experienced users needing precise control over PLC operations, while Sequential Function Chart (SFC) provides a visual, step-by-step representation, making complex processes easier to manage and debug. Selecting between IL and SFC depends on project complexity, programmer expertise, and the need for readability versus granular control. For straightforward, sequence-driven projects, SFC improves clarity and maintenance; complex algorithms benefiting from optimized code execution are better suited for IL.

Instruction List Infographic

libterm.com

libterm.com