Permanent Magnet Synchronous Motors (PMSMs) offer high efficiency and precise control, making them ideal for applications in electric vehicles, robotics, and industrial machinery. Their use of permanent magnets reduces energy loss and enhances performance compared to traditional induction motors. Discover how PMSM motors can improve your system's reliability and efficiency by exploring the detailed insights in the rest of this article.

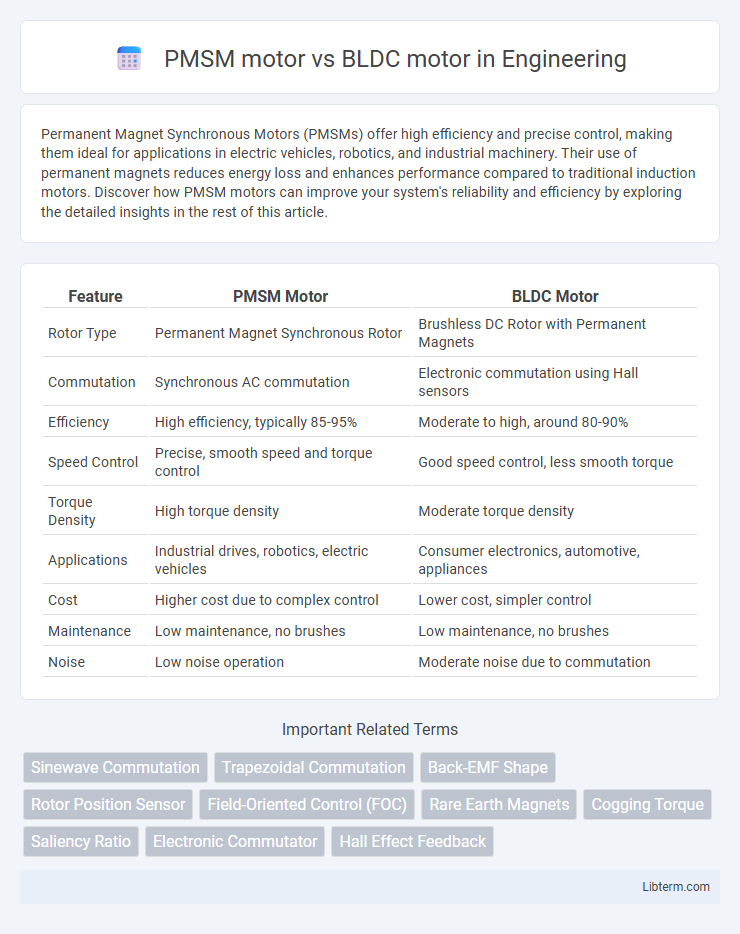

Table of Comparison

| Feature | PMSM Motor | BLDC Motor |

|---|---|---|

| Rotor Type | Permanent Magnet Synchronous Rotor | Brushless DC Rotor with Permanent Magnets |

| Commutation | Synchronous AC commutation | Electronic commutation using Hall sensors |

| Efficiency | High efficiency, typically 85-95% | Moderate to high, around 80-90% |

| Speed Control | Precise, smooth speed and torque control | Good speed control, less smooth torque |

| Torque Density | High torque density | Moderate torque density |

| Applications | Industrial drives, robotics, electric vehicles | Consumer electronics, automotive, appliances |

| Cost | Higher cost due to complex control | Lower cost, simpler control |

| Maintenance | Low maintenance, no brushes | Low maintenance, no brushes |

| Noise | Low noise operation | Moderate noise due to commutation |

Introduction to PMSM and BLDC Motors

Permanent Magnet Synchronous Motors (PMSM) utilize permanent magnets embedded in the rotor to generate a constant magnetic field, allowing for high efficiency and precise control in applications like electric vehicles and industrial automation. Brushless DC (BLDC) motors also use permanent magnets but rely on electronic commutation to control the stator windings, providing a compact design with high torque-to-weight ratios and reduced maintenance due to the absence of brushes. Both PMSM and BLDC motors are valued for their reliability and performance advantages over traditional brushed motors, with PMSMs excelling in smooth operation and BLDCs favored for simplicity and cost-effectiveness.

Basic Construction Differences

PMSM motors feature a rotor with permanent magnets embedded or surface-mounted on a steel core, giving them a smooth, sinusoidal back-EMF waveform and enabling precise control. BLDC motors have a rotor with permanent magnets and a stator with distributed windings designed to produce a trapezoidal back-EMF, simplifying commutation with Hall sensors. The fundamental construction difference lies in the rotor magnet placement and stator winding design, which directly impact their electromagnetic performance and control methods.

Working Principle Comparison

Permanent Magnet Synchronous Motors (PMSMs) operate by synchronizing the rotor's permanent magnets with a rotating magnetic field generated by the stator windings, ensuring continuous torque production with sinusoidal current waveforms. Brushless DC (BLDC) motors use electronically commutated stator currents to energize stator windings in a trapezoidal waveform, resulting in a stepwise rotor motion aligned with the magnetic poles. The core distinction lies in PMSMs maintaining synchronous rotor speed with smooth torque via sinusoidal excitation, whereas BLDC motors achieve rotation through discrete phase energizing and trapezoidal back-EMF patterns.

Rotor and Stator Design Contrast

PMSM motors feature a rotor with surface-mounted or embedded permanent magnets, resulting in smooth torque and high efficiency, whereas BLDC motors use a rotor with permanent magnets but typically have a trapezoidal back-EMF waveform due to their distinct coil arrangement. The stator of a PMSM usually has distributed windings for sinusoidal current distribution, enhancing precision and reducing torque ripple, while BLDC stators often have concentrated windings optimized for digital commutation. These design contrasts influence the motors' electromagnetic performance, control strategies, and applications in high-precision vs. cost-sensitive environments.

Performance Efficiency: PMSM vs BLDC

Permanent Magnet Synchronous Motors (PMSM) exhibit higher performance efficiency compared to Brushless DC Motors (BLDC) due to their sinusoidal back-EMF waveform and optimized electromagnetic design, which result in smoother torque and reduced torque ripple. PMSMs maintain superior efficiency across a wider speed range, particularly at high speeds, by minimizing electrical losses and improving power density. In contrast, BLDC motors with trapezoidal back-EMF have slightly lower efficiency and increased torque ripple, limiting their performance in precision applications.

Commutation Methods: Electronic vs Mechanical

PMSM motors utilize electronic commutation through precise control of sinusoidal waveforms generated by sensors or sensorless algorithms, resulting in smoother torque and higher efficiency. BLDC motors rely on electronic commutation driven by trapezoidal waveforms, typically using Hall effect sensors or sensorless methods to time the switching of phases. Mechanical commutation, as seen in brushed DC motors, is absent in both PMSM and BLDC motors, eliminating wear-prone brushes and enabling higher reliability and lower maintenance.

Control Techniques and Complexity

PMSM motors require sophisticated control techniques such as Field-Oriented Control (FOC) to achieve precise torque and speed management, leveraging rotor position feedback for sinusoidal current control. BLDC motors typically use trapezoidal control methods with simpler Hall sensor-based commutation, resulting in lower control complexity. The advanced control algorithms of PMSMs enable higher efficiency and smoother operation, while BLDCs offer easier, cost-effective control with moderate performance.

Applications of PMSM and BLDC Motors

PMSM motors are widely used in high-performance industrial applications such as robotics, aerospace, and electric vehicles due to their high efficiency, precise speed control, and ability to handle high torque at low speeds. BLDC motors are commonly found in consumer electronics, HVAC systems, and automotive components, favored for their cost-effectiveness, low maintenance, and reliable operation in variable speed applications. Both motor types serve critical roles in renewable energy systems and automation, with PMSM preferred for demanding precision tasks and BLDC for cost-sensitive, general-purpose uses.

Cost and Maintenance Considerations

PMSM motors generally have higher initial costs due to their complex rotor design and use of rare-earth magnets, but they offer greater efficiency and longer lifespan, reducing long-term maintenance expenses. BLDC motors, while more affordable upfront and simpler to maintain because of their robust electronic commutation, may require more frequent servicing due to mechanical wear in sensor systems. Evaluating total cost of ownership reveals PMSMs as more cost-effective in high-performance applications, whereas BLDC motors suit budget-conscious projects with moderate maintenance capabilities.

Choosing the Right Motor: PMSM or BLDC

PMSM motors offer higher efficiency and better torque density, making them ideal for applications requiring precise control and smooth operation. BLDC motors excel in cost-effectiveness and simplicity, suited for applications needing robust performance with minimal maintenance. Selecting between PMSM and BLDC motors depends on the specific requirements such as efficiency, control complexity, and budget constraints.

PMSM motor Infographic

libterm.com

libterm.com