Ball valves provide reliable, tight shutoff and control in piping systems, featuring a rotating ball to regulate flow with minimal pressure drop. Their durable design offers ease of operation and low maintenance, making them ideal for various industrial applications. Discover how ball valves can enhance Your fluid control solutions by reading the rest of the article.

Table of Comparison

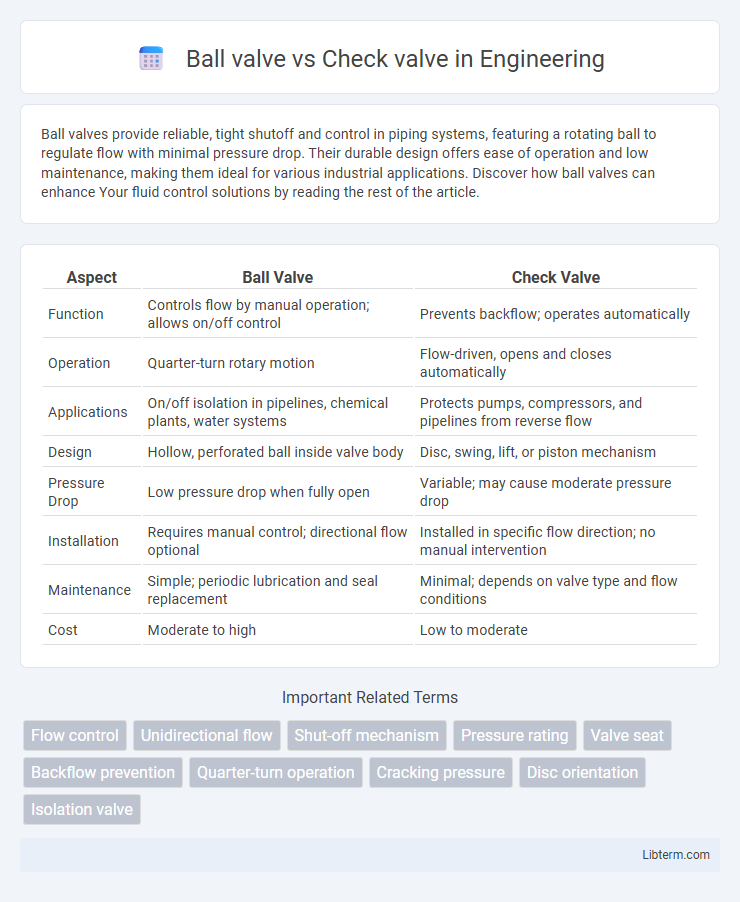

| Aspect | Ball Valve | Check Valve |

|---|---|---|

| Function | Controls flow by manual operation; allows on/off control | Prevents backflow; operates automatically |

| Operation | Quarter-turn rotary motion | Flow-driven, opens and closes automatically |

| Applications | On/off isolation in pipelines, chemical plants, water systems | Protects pumps, compressors, and pipelines from reverse flow |

| Design | Hollow, perforated ball inside valve body | Disc, swing, lift, or piston mechanism |

| Pressure Drop | Low pressure drop when fully open | Variable; may cause moderate pressure drop |

| Installation | Requires manual control; directional flow optional | Installed in specific flow direction; no manual intervention |

| Maintenance | Simple; periodic lubrication and seal replacement | Minimal; depends on valve type and flow conditions |

| Cost | Moderate to high | Low to moderate |

Introduction to Ball Valves and Check Valves

Ball valves are quarter-turn valves designed to provide reliable shut-off by using a spherical disc to control flow, often used in pipelines requiring quick shut-off and downstream isolation. Check valves allow fluid to flow in one direction only, preventing backflow and protecting pumps and compressors by automatically closing when reverse flow is detected. Both valves serve critical roles in fluid control systems but differ significantly in design and application, with ball valves primarily controlling flow manually and check valves acting as automatic safety devices.

Key Differences Between Ball Valves and Check Valves

Ball valves provide precise flow control through a rotatable ball with a bore, enabling quick shutoff in fluid systems, whereas check valves allow flow in only one direction, preventing backflow automatically without manual intervention. Ball valves are operated manually or automatically via a lever or actuator, while check valves function passively using internal mechanisms like springs or discs to maintain unidirectional flow. Key differences include ball valves' ability to control and isolate flow actively versus check valves' role in safeguarding system integrity by preventing reverse flow.

How Ball Valves Work

Ball valves operate by rotating a spherical ball with a bore through its center inside the valve body, allowing fluid to flow when the bore aligns with the pipeline. Turning the valve handle 90 degrees rotates the ball to either open or close the flow path, providing quick and reliable shutoff. These valves are widely used in applications requiring tight sealing and minimal pressure drop, such as oil and gas pipelines and water supply systems.

How Check Valves Function

Check valves function by allowing fluid to flow in one direction while preventing backflow, using internal components such as a spring-loaded disc, ball, or flap that automatically closes when reverse pressure occurs. Unlike ball valves that require manual or actuated control for opening and closing, check valves operate passively based on pressure differentials, ensuring unidirectional flow in piping systems. This mechanism protects pumps, compressors, and other equipment from damage caused by reverse flow or back pressure.

Common Applications of Ball Valves

Ball valves are widely used in industries requiring reliable shut-off and flow control, such as oil and gas, water treatment, and chemical processing. Their quick quarter-turn operation and tight sealing make them ideal for applications involving high pressure and temperature. Check valves, in contrast, are typically installed to prevent backflow in piping systems, ensuring unidirectional flow without manual intervention.

Typical Uses of Check Valves

Check valves are primarily used in systems where backflow prevention is critical, such as in water and wastewater treatment, chemical processing, and HVAC applications. These valves allow fluid to flow in one direction only, protecting pumps, compressors, and other equipment from potential damage caused by reverse flow. Typical placements include pipeline discharge lines, pump outlets, and fuel systems where unidirectional flow control enhances operational safety and efficiency.

Advantages of Ball Valves

Ball valves provide superior control with a tight seal, ensuring minimal leakage and efficient flow regulation in pipelines. They offer faster operation due to their quarter-turn mechanism and are highly durable, capable of handling high pressure and temperature conditions. Unlike check valves, ball valves allow for manual flow control, making them versatile for various industrial applications.

Benefits of Check Valves

Check valves prevent backflow, ensuring unidirectional fluid flow which protects pumps and compressors from damage. Their simple, automatic operation reduces maintenance needs and enhances system reliability in pipelines and industrial processes. Check valves also minimize water hammer effects and pressure surges, improving the overall safety and efficiency of fluid handling systems.

Choosing Between Ball Valve and Check Valve

Choosing between a ball valve and a check valve depends on the application requirements for flow control and backflow prevention. Ball valves provide reliable shutoff and precise flow regulation using a rotary ball mechanism, making them ideal for manual or automated isolation in pipelines. Check valves automatically prevent reverse flow without manual operation, ensuring system protection in applications like pumps or compressors where backflow could cause damage.

Conclusion: Ball Valve vs Check Valve

Ball valves provide precise flow control with easy operation through a rotary ball mechanism, making them ideal for on/off applications requiring tight shutoff. Check valves allow unidirectional flow automatically, preventing backflow without manual intervention, crucial in systems with potential reverse flow risks. Selecting between ball valves and check valves depends on whether active flow control or passive flow prevention is the primary need in the piping system.

Ball valve Infographic

libterm.com

libterm.com