Creep describes the slow, permanent deformation of materials under constant stress, often occurring in metals, polymers, and rocks at high temperatures. Understanding creep behavior is essential for predicting the lifespan and ensuring the safety of structural components in engineering applications. Discover how creep affects your materials and learn methods to minimize its impact in the rest of this article.

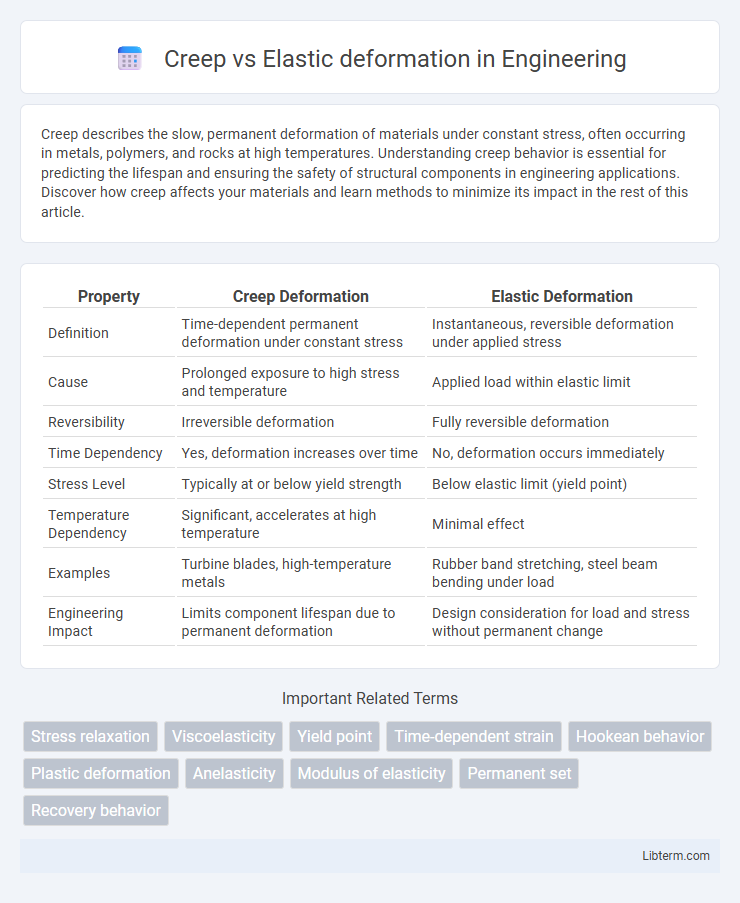

Table of Comparison

| Property | Creep Deformation | Elastic Deformation |

|---|---|---|

| Definition | Time-dependent permanent deformation under constant stress | Instantaneous, reversible deformation under applied stress |

| Cause | Prolonged exposure to high stress and temperature | Applied load within elastic limit |

| Reversibility | Irreversible deformation | Fully reversible deformation |

| Time Dependency | Yes, deformation increases over time | No, deformation occurs immediately |

| Stress Level | Typically at or below yield strength | Below elastic limit (yield point) |

| Temperature Dependency | Significant, accelerates at high temperature | Minimal effect |

| Examples | Turbine blades, high-temperature metals | Rubber band stretching, steel beam bending under load |

| Engineering Impact | Limits component lifespan due to permanent deformation | Design consideration for load and stress without permanent change |

Introduction to Deformation: Creep vs. Elastic

Elastic deformation occurs when a material reversibly changes shape under stress, returning to its original form once the load is removed, characterized by immediate strain proportional to the applied stress according to Hooke's law. Creep deformation refers to the time-dependent, permanent strain that develops when a material is subjected to a constant load over an extended period, often observed at high temperatures relative to the material's melting point. Understanding the fundamental difference between elastic and creep deformation is essential for predicting material performance and failure in engineering applications.

Fundamental Differences: Creep and Elastic Deformation

Creep is a time-dependent, permanent deformation occurring in materials under constant stress at elevated temperatures, while elastic deformation is a reversible change in shape or size that disappears immediately upon removal of the applied load. Creep involves atomic diffusion and dislocation motion leading to gradual elongation, whereas elastic deformation relies on the stretching of atomic bonds without permanent displacement. The fundamental difference lies in creep's irreversibility and long-term strain accumulation versus elastic deformation's instantaneous and recoverable nature.

Causes and Conditions of Creep

Creep deformation occurs under prolonged exposure to constant stress at elevated temperatures, typically above 0.4 times the material's melting point in Kelvin, causing time-dependent plastic strain due to atomic diffusion and dislocation movement. Elastic deformation results from applied stresses below the yield strength, where material returns to its original shape after load removal, driven by atomic bond stretching without permanent displacement. Creep conditions often involve high temperature, sustained load, and specific microstructural characteristics such as grain boundary sliding and vacancy migration, distinguishing it from instantaneous elastic deformation.

Characteristics of Elastic Deformation

Elastic deformation is characterized by immediate, reversible changes in a material's shape when subjected to stress, maintaining atomic bonds without permanent displacement. The deformation is proportional to the applied load within the elastic limit, as described by Hooke's Law, and the material returns to its original shape upon load removal. Elastic deformation occurs over short time scales and does not involve time-dependent strain or permanent structural changes.

Material Behavior Under Stress: Elastic vs. Creep

Elastic deformation occurs when a material returns to its original shape after the applied stress is removed, emphasizing reversible atomic bond stretching. Creep deformation happens under constant stress over time, causing permanent, time-dependent strain due to mechanisms like dislocation movement and diffusion at elevated temperatures. Understanding the distinction between elastic and creep behavior is crucial for designing materials subjected to long-term loading and high-temperature environments to ensure structural integrity.

Time-Dependence in Creep Deformation

Creep deformation is inherently time-dependent, occurring gradually under constant stress as atoms or molecules slowly rearrange, resulting in permanent strain over extended periods. Elastic deformation, however, is instantaneous and reversible, where material returns to its original shape immediately upon stress removal. The time dependence in creep is critical for materials subjected to prolonged high temperatures or stresses, significantly affecting their long-term mechanical performance.

Stress-Strain Relationship: Elasticity vs. Creep

Elastic deformation occurs when a material undergoes temporary shape change under applied stress, returning to its original form once the stress is removed, characterized by a linear stress-strain relationship defined by Hooke's Law within the elastic limit. Creep deformation involves time-dependent, permanent strain occurring under constant stress at elevated temperatures, where the stress-strain curve exhibits a slowly increasing strain with time despite constant stress levels. The key difference in stress-strain behavior is that elasticity shows instantaneous and reversible strain proportional to stress, while creep demonstrates gradual, irreversible strain accumulation under sustained load.

Factors Influencing Creep and Elastic Deformation

Temperature significantly impacts creep deformation by accelerating atomic diffusion and dislocation movement, leading to permanent strain under constant stress. Elastic deformation depends primarily on material properties such as Young's modulus and the stress applied, where strain remains fully recoverable upon load removal. Time and stress levels are crucial in creep, with higher stress and prolonged exposure causing greater deformation, whereas elastic deformation is instantaneous and reversible within the elastic limit.

Real-World Applications: When Creep or Elasticity Matters

In high-temperature turbine blades and power plant components, creep deformation is critical to assess for long-term durability under sustained stress. Elastic deformation plays a key role in designing automotive suspension systems and bridges, where materials must return to their original shape after load removal. Understanding the conditions where creep or elasticity dominates ensures structural integrity and safety in aerospace, civil engineering, and industrial applications.

Summary: Choosing Materials Based on Deformation Properties

Creep deformation occurs under sustained stress at high temperatures, leading to permanent, time-dependent strain, whereas elastic deformation is reversible and occurs immediately upon stress application. Selecting materials with low creep rates is crucial for high-temperature applications like turbine blades, while materials with high elastic limit and modulus are preferred for components requiring reliable, repeatable deformation under load. Understanding these deformation behaviors ensures optimal performance and longevity in engineering designs across various industries.

Creep Infographic

libterm.com

libterm.com