Tunnel form construction accelerates building projects by combining formwork and concrete pouring into a single, efficient process. This method enhances structural integrity and reduces labor costs, making it ideal for repetitive residential and commercial developments. Explore the rest of the article to understand how tunnel form can transform your construction timeline and budget.

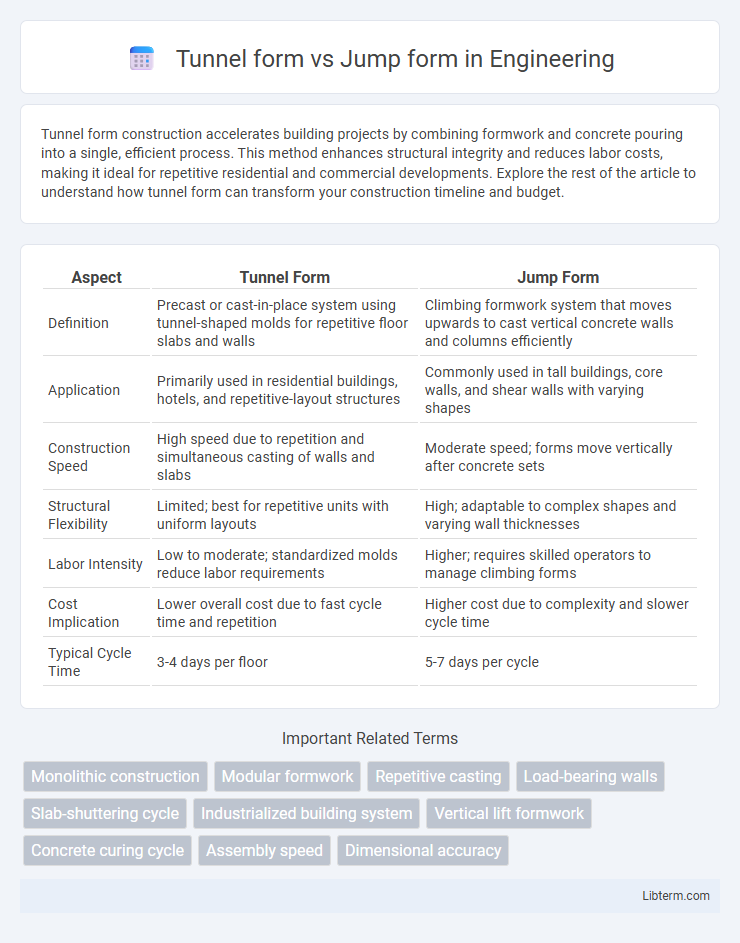

Table of Comparison

| Aspect | Tunnel Form | Jump Form |

|---|---|---|

| Definition | Precast or cast-in-place system using tunnel-shaped molds for repetitive floor slabs and walls | Climbing formwork system that moves upwards to cast vertical concrete walls and columns efficiently |

| Application | Primarily used in residential buildings, hotels, and repetitive-layout structures | Commonly used in tall buildings, core walls, and shear walls with varying shapes |

| Construction Speed | High speed due to repetition and simultaneous casting of walls and slabs | Moderate speed; forms move vertically after concrete sets |

| Structural Flexibility | Limited; best for repetitive units with uniform layouts | High; adaptable to complex shapes and varying wall thicknesses |

| Labor Intensity | Low to moderate; standardized molds reduce labor requirements | Higher; requires skilled operators to manage climbing forms |

| Cost Implication | Lower overall cost due to fast cycle time and repetition | Higher cost due to complexity and slower cycle time |

| Typical Cycle Time | 3-4 days per floor | 5-7 days per cycle |

Introduction to Tunnel Form and Jump Form

Tunnel form construction speeds up the building of repetitive concrete structures by using a modular steel formwork that shapes walls and slabs simultaneously, optimizing labor and time efficiency for residential and commercial projects. Jump form is a climbing formwork system designed for vertical structures like high-rise buildings, allowing the formwork to be lifted progressively as construction advances, enhancing safety and structural uniformity. Both systems prioritize faster cycle times and reduced labor costs, with tunnel form better suited for horizontal floor slabs and jump form ideal for vertical core walls and columns.

Construction Process Overview

Tunnel form construction uses reusable steel forms to cast entire concrete walls and slabs in a single operation, accelerating the construction of repetitive floor plans with high structural efficiency. Jump form construction employs climbing formwork that moves vertically along the building, ideal for tall structures with variable floor designs by facilitating continuous vertical concrete pouring cycles. Both methods optimize construction speed and labor efficiency but differ in formwork mobility and application suitability.

Speed and Efficiency Comparison

Tunnel form construction accelerates project timelines by enabling simultaneous casting of walls and slabs, leading to a rapid cycle time of 3 to 5 days per floor. Jump form systems offer flexibility for taller structures by allowing continuous vertical climbing, but typically require 5 to 7 days per floor, making tunnel form faster for repetitive, mid-rise buildings. Efficiency in tunnel form arises from repetitive formwork reuse and integrated installation, whereas jump form prioritizes adaptability in complex high-rise designs.

Structural Quality and Finish

Tunnel form offers superior structural quality due to its continuous casting process, which ensures uniform concrete density and reduces joint weaknesses, enhancing overall durability and seismic resistance. In contrast, jump form provides flexibility in complex geometries but may introduce more construction joints, potentially affecting waterproofing and long-term structural integrity. Surface finish in tunnel form is typically smoother and more consistent, minimizing the need for extensive plastering, whereas jump form may require additional finishing work to achieve comparable aesthetic quality.

Cost Implications

Tunnel form construction generally offers lower labor costs and faster cycle times due to repetitive modular units and integrated formwork, reducing on-site work duration. Jump form, while potentially more expensive upfront because of specialized climbing formwork systems, allows for greater flexibility and higher structural complexity, which may increase total project costs in intricate builds. Cost implications must consider project scale, complexity, and labor efficiency when choosing between tunnel form and jump form methodologies.

Labor and Skill Requirements

Tunnel form construction demands labor skilled in repetitive, high-precision concrete casting and formwork assembly to ensure fast cycle times and structural accuracy. Jump form requires workers experienced in climbing form systems and coordination for vertical progression, emphasizing safety and teamwork under tight schedules. Both methods necessitate specialized training, but jump form labor often faces higher complexity due to continuous adjustments and climbing form movements.

Flexibility in Design and Application

Tunnel form construction offers limited flexibility due to its repetitive, standardized formwork primarily used for repetitive residential or hotel projects. Jump form construction provides greater design adaptability, allowing varied floor layouts and complex architectural shapes ideal for commercial and high-rise buildings. The choice between tunnel form and jump form depends on project complexity, with jump form excelling in custom designs and tunnel form favoring speed and uniformity.

Safety Considerations

Tunnel form construction offers enhanced safety by providing a stable, repetitive formwork system that reduces worker exposure to fall hazards during concrete pouring and curing. Jump form systems require constant repositioning at height, increasing risks related to scaffolding stability and worker falls without stringent safety protocols. Implementing strict fall protection measures and regular equipment inspections is critical for minimizing accidents in both tunnel form and jump form construction.

Environmental Impact

Tunnel form construction minimizes environmental impact by optimizing repetitive formwork, reducing material waste and energy consumption during concrete curing, and shortening project timelines, which lowers overall emissions. Jump form systems, while flexible for high-rise buildings, often require more formwork components and crane usage, leading to increased energy use and carbon footprint. Sustainable project strategies favor tunnel form for its efficiency in resource utilization and lower ecological disturbance.

Best Use Cases

Tunnel form construction excels in rapid repetitive floor slab casting, ideal for residential buildings and hotels with uniform floor layouts, enabling shorter cycle times and consistent quality. Jump form is best suited for complex vertical structures such as high-rise office towers and core walls, offering flexibility to adapt to varying floor plans and heights. Both methods optimize productivity but selecting tunnel form maximizes efficiency in repetitive designs, while jump form accommodates architectural complexity and structural variation.

Tunnel form Infographic

libterm.com

libterm.com