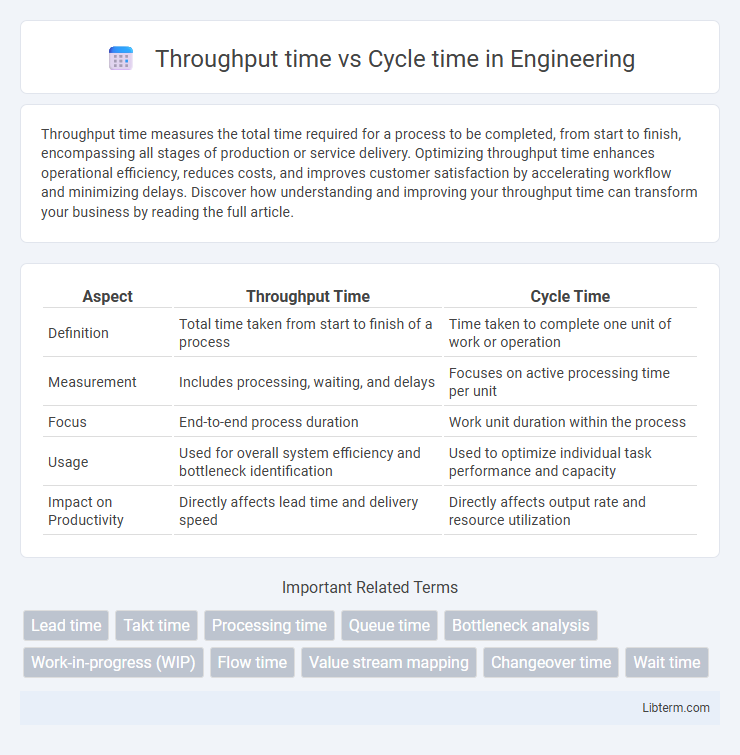

Throughput time measures the total time required for a process to be completed, from start to finish, encompassing all stages of production or service delivery. Optimizing throughput time enhances operational efficiency, reduces costs, and improves customer satisfaction by accelerating workflow and minimizing delays. Discover how understanding and improving your throughput time can transform your business by reading the full article.

Table of Comparison

| Aspect | Throughput Time | Cycle Time |

|---|---|---|

| Definition | Total time taken from start to finish of a process | Time taken to complete one unit of work or operation |

| Measurement | Includes processing, waiting, and delays | Focuses on active processing time per unit |

| Focus | End-to-end process duration | Work unit duration within the process |

| Usage | Used for overall system efficiency and bottleneck identification | Used to optimize individual task performance and capacity |

| Impact on Productivity | Directly affects lead time and delivery speed | Directly affects output rate and resource utilization |

Introduction to Throughput Time and Cycle Time

Throughput time refers to the total time taken for a product or service to pass through an entire process from start to finish, encompassing all stages including waiting and processing times. Cycle time measures the time required to complete a single unit of work or task within a production cycle, often reflecting the pace of operations on a specific work center. Understanding the distinction between throughput time and cycle time is crucial for optimizing manufacturing efficiency and identifying bottlenecks in production workflows.

Defining Throughput Time

Throughput time refers to the total time taken for a product or service to pass through a complete process, from start to finish, including waiting, processing, and transfer times. It differs from cycle time, which measures the time taken to complete a single unit or task within the process. Understanding throughput time is critical for optimizing overall process efficiency and identifying bottlenecks in production or service workflows.

Understanding Cycle Time

Cycle time measures the time taken to complete one unit of a process from start to finish, reflecting the pace of production. This metric helps identify bottlenecks by tracking the duration of each task within the workflow. Understanding cycle time enables businesses to optimize resource allocation and improve process efficiency, directly impacting overall throughput time.

Key Differences Between Throughput Time and Cycle Time

Throughput time measures the total duration from the start to the completion of a process, encompassing all waiting, processing, and queue times. Cycle time specifically refers to the time taken to complete one unit of work or process segment, excluding idle times and delays. Understanding the distinction between throughput time and cycle time is crucial for optimizing production efficiency and identifying bottlenecks in manufacturing and service operations.

Importance of Measuring Time Metrics in Business Processes

Measuring throughput time and cycle time is essential for optimizing business processes, as these metrics provide critical insights into process efficiency and bottlenecks. Throughput time reflects the total time from the start to the end of a process, revealing overall lead time, while cycle time captures the time taken to complete each individual task within the process. Accurate analysis of these metrics supports data-driven decisions, improves resource allocation, and accelerates process improvements to enhance customer satisfaction and operational performance.

Factors Influencing Throughput Time

Throughput time is influenced by factors such as machine efficiency, workforce skill levels, and process bottlenecks that slow down production flow. Variability in raw material quality and equipment maintenance schedules also directly impact the overall time required to complete a product cycle. Optimizing layout design and reducing setup times are critical strategies to minimize throughput time and enhance operational performance.

Factors Affecting Cycle Time

Cycle time is influenced by factors such as machine efficiency, worker skill level, and process complexity, which directly determine the duration for completing a single unit of work. Variability in task performance, equipment downtime, and setup times also impact cycle time by causing delays and inconsistencies. Efficient resource allocation and streamlined workflows minimize cycle time, enhancing overall production speed compared to throughput time, which measures total processing plus waiting times.

Practical Examples: Throughput Time vs Cycle Time

Throughput time measures the total time taken for a product to move through the entire production process, such as a car assembly line where it captures the duration from raw material input to finished vehicle output. Cycle time represents the time taken to complete one unit of work within a specific process, for example, the time needed to install a door on a vehicle during assembly. In practical terms, reducing cycle time in each step can lower overall throughput time, improving manufacturing efficiency and delivery speed.

Strategies for Reducing Time Metrics

Reducing throughput time and cycle time can be achieved by implementing process automation and streamlining workflows to eliminate bottlenecks. Lean manufacturing techniques such as value stream mapping help identify inefficiencies and reduce non-value-added activities, directly improving both throughput and cycle times. Continuous monitoring using key performance indicators (KPIs) ensures timely adjustments that optimize overall production speed and resource utilization.

Conclusion: Choosing the Right Metric for Optimization

Throughput time measures the total duration from the start to the end of a process, encompassing all waiting and processing times, while cycle time focuses on the time to complete a single unit of work within the process. Selecting throughput time is ideal for optimizing overall process efficiency and identifying bottlenecks, whereas cycle time suits tasks requiring focus on individual unit performance and productivity improvements. Businesses should align metric choice with operational goals, using throughput time for end-to-end process enhancement and cycle time for granular task optimization.

Throughput time Infographic

libterm.com

libterm.com