Thickness plays a crucial role in determining the strength, durability, and overall performance of materials across various applications. Understanding how thickness affects insulation, structural integrity, and aesthetic appeal can help you make informed decisions in construction, manufacturing, and design projects. Explore the rest of the article to learn more about optimizing thickness for your specific needs.

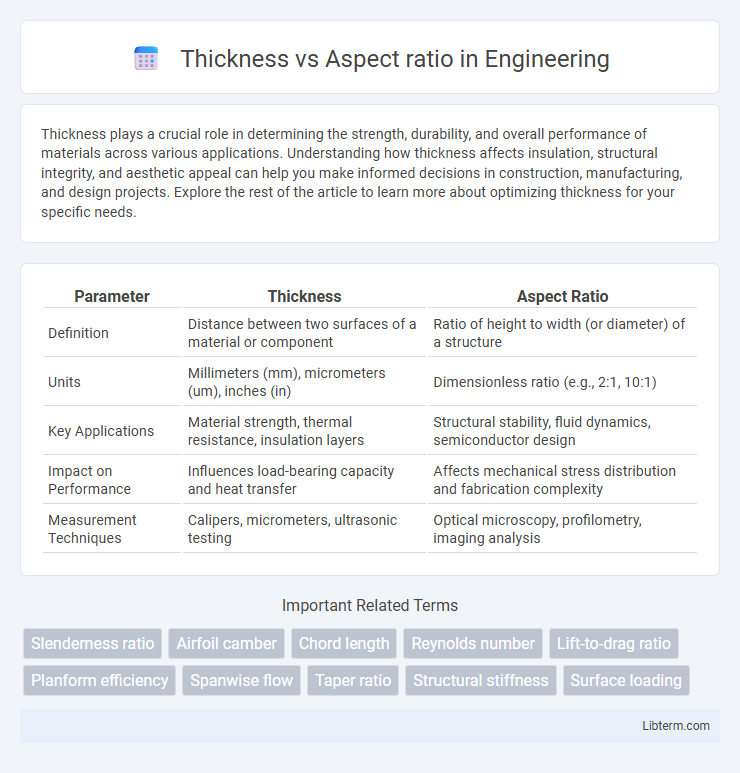

Table of Comparison

| Parameter | Thickness | Aspect Ratio |

|---|---|---|

| Definition | Distance between two surfaces of a material or component | Ratio of height to width (or diameter) of a structure |

| Units | Millimeters (mm), micrometers (um), inches (in) | Dimensionless ratio (e.g., 2:1, 10:1) |

| Key Applications | Material strength, thermal resistance, insulation layers | Structural stability, fluid dynamics, semiconductor design |

| Impact on Performance | Influences load-bearing capacity and heat transfer | Affects mechanical stress distribution and fabrication complexity |

| Measurement Techniques | Calipers, micrometers, ultrasonic testing | Optical microscopy, profilometry, imaging analysis |

Introduction to Thickness and Aspect Ratio

Thickness refers to the measurement of a material's depth or dimension between its two opposite surfaces, often critical in determining strength and durability. Aspect ratio is the proportional relationship between width and height, widely used in fields like engineering and graphics to describe shapes and structures. Understanding the interplay between thickness and aspect ratio helps optimize design performance, ensuring stability and efficiency in various applications.

Defining Thickness and Aspect Ratio

Thickness refers to the measurement of the distance between two surfaces of a material or object, typically expressed in units such as millimeters or micrometers. Aspect ratio is the proportional relationship between the width and height of an object, commonly calculated as width divided by height, indicating the object's overall shape characteristics. Both thickness and aspect ratio are critical parameters in fields like materials science, engineering, and design, affecting structural integrity and visual proportions.

Importance of Thickness in Material Performance

Thickness plays a critical role in determining the mechanical strength, thermal insulation, and durability of materials, directly influencing their performance in various applications. A thicker material often enhances load-bearing capacity and resistance to wear, while also affecting thermal conductivity and sound insulation properties. Optimizing thickness is essential for balancing material efficiency, cost, and functional requirements in engineering and manufacturing processes.

Impact of Aspect Ratio on Structural Behavior

The aspect ratio significantly influences the structural behavior by dictating stress distribution and deformation patterns within a material or component. High aspect ratios typically lead to increased susceptibility to buckling and bending, affecting stiffness and load-bearing capacity. Optimizing aspect ratio alongside thickness enhances structural stability and performance under various loading conditions.

Relationship Between Thickness and Aspect Ratio

The relationship between thickness and aspect ratio is critical in structural and material sciences, where aspect ratio is defined as the ratio of length to thickness. As the thickness of a material or component increases, the aspect ratio typically decreases, impacting mechanical properties such as strength and flexibility. Understanding this inverse relationship enables more precise design and optimization of materials in fields like aerospace, microelectronics, and biomechanics.

Applications Affected by Thickness vs Aspect Ratio

Thickness directly influences mechanical strength and thermal conductivity, whereas aspect ratio affects surface area-to-volume ratio and fluid dynamics. Microelectromechanical systems (MEMS) benefit from precise thickness control to maintain flexibility, while high aspect ratio structures in semiconductor fabrication enhance electron mobility and heat dissipation. In battery electrodes, optimized thickness ensures sufficient energy storage, and aspect ratio adjustments improve ion transport efficiency.

Advantages and Disadvantages of Varying Thickness

Varying thickness in materials significantly affects the aspect ratio, impacting mechanical strength and flexibility. Thicker materials provide enhanced durability and load-bearing capacity but often result in increased weight and reduced flexibility, limiting applications requiring lightweight components. Conversely, thinner materials offer better flexibility and reduced weight, advantageous for compact designs, though they may compromise structural integrity and wear resistance.

Optimizing Aspect Ratio for Specific Uses

Optimizing aspect ratio involves balancing thickness and width to enhance performance in applications such as microelectronics, structural components, and flexible displays. A lower thickness-to-width ratio improves flexibility and reduces material stress, crucial for wearable technology and bendable screens, while higher ratios increase strength and rigidity for load-bearing uses. Tailoring the aspect ratio to specific functional requirements ensures durability, efficiency, and optimal material utilization in advanced manufacturing processes.

Common Mistakes in Balancing Thickness and Aspect Ratio

Common mistakes in balancing thickness and aspect ratio include neglecting the impact of a high aspect ratio on structural integrity, leading to overly thin elements prone to failure. Overemphasizing thickness without adjusting the aspect ratio can cause unnecessary material usage and increased weight. Engineers often overlook the nonlinear relationship between thickness and aspect ratio, resulting in compromised performance and inefficient designs.

Future Trends in Thickness and Aspect Ratio Design

Future trends in thickness and aspect ratio design emphasize ultra-thin profiles combined with high aspect ratios to enhance performance in microelectronics and flexible displays. Advanced materials like graphene and novel fabrication techniques enable precise control of thickness at the nanoscale while maintaining structural integrity at extreme aspect ratios. Integration of AI-driven design tools further optimizes these parameters to meet evolving demands for miniaturization, efficiency, and durability in next-generation devices.

Thickness Infographic

libterm.com

libterm.com