Lubricated friction occurs when a thin layer of lubricant separates two sliding surfaces, reducing direct contact and minimizing wear and heat generation. This process significantly improves the efficiency and lifespan of mechanical components by lowering frictional resistance. Discover how understanding lubricated friction can enhance your machinery's performance by reading the rest of the article.

Table of Comparison

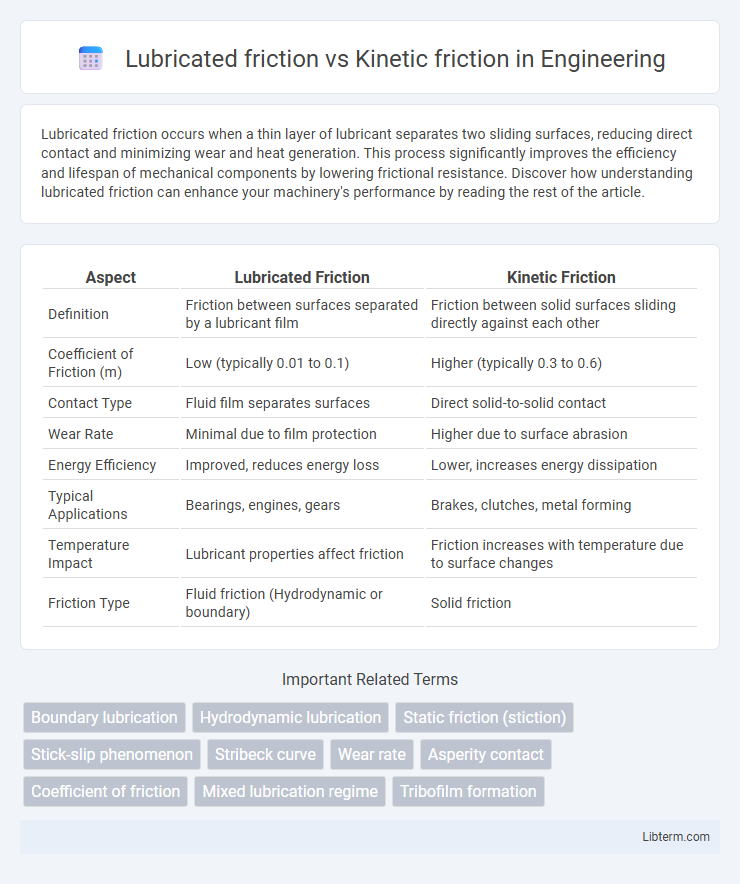

| Aspect | Lubricated Friction | Kinetic Friction |

|---|---|---|

| Definition | Friction between surfaces separated by a lubricant film | Friction between solid surfaces sliding directly against each other |

| Coefficient of Friction (m) | Low (typically 0.01 to 0.1) | Higher (typically 0.3 to 0.6) |

| Contact Type | Fluid film separates surfaces | Direct solid-to-solid contact |

| Wear Rate | Minimal due to film protection | Higher due to surface abrasion |

| Energy Efficiency | Improved, reduces energy loss | Lower, increases energy dissipation |

| Typical Applications | Bearings, engines, gears | Brakes, clutches, metal forming |

| Temperature Impact | Lubricant properties affect friction | Friction increases with temperature due to surface changes |

| Friction Type | Fluid friction (Hydrodynamic or boundary) | Solid friction |

Introduction to Lubricated and Kinetic Friction

Lubricated friction occurs when a lubricant, such as oil or grease, is applied between two surfaces, significantly reducing the resistance to motion by creating a thin film that separates the surfaces. Kinetic friction, also known as sliding friction, arises when two solid surfaces slide against each other without lubrication, resulting in higher resistance due to direct surface contact. The primary difference lies in the presence of a lubricant, which lowers kinetic friction by minimizing surface asperities and wear.

Defining Lubricated Friction

Lubricated friction occurs when a thin layer of lubricant, such as oil or grease, separates two sliding surfaces, significantly reducing direct contact and frictional resistance. This type of friction contrasts with kinetic friction, which happens between dry, solid surfaces in relative motion without any lubrication. The presence of lubricant films minimizes wear and heat generation, enhancing the efficiency and lifespan of mechanical components.

Understanding Kinetic (Sliding) Friction

Kinetic friction, also known as sliding friction, occurs when two surfaces move relative to each other, opposing the motion with a force proportional to the normal load and characterized by a nearly constant coefficient of kinetic friction. In lubricated friction, a lubricant layer reduces direct surface contact, significantly lowering the kinetic friction coefficient and minimizing wear and heat generation. Understanding the dynamics of kinetic friction is crucial for optimizing mechanical systems, as it influences energy efficiency and component lifespan in applications ranging from automotive brakes to industrial machinery.

Key Differences Between Lubricated and Kinetic Friction

Lubricated friction occurs when a lubricant, such as oil or grease, creates a thin film between surfaces, significantly reducing resistance and wear, whereas kinetic friction acts between two sliding surfaces in direct contact without any lubricant. The coefficient of friction in lubricated friction is much lower compared to kinetic friction, resulting in smoother motion and less heat generation. Lubricated friction is essential in machinery to enhance efficiency and longevity, while kinetic friction plays a critical role in everyday activities by resisting motion and providing necessary traction.

Factors Influencing Lubricated Friction

Lubricated friction significantly reduces kinetic friction by forming a fluid film that separates contacting surfaces, minimizing direct asperity contact and wear. Factors influencing lubricated friction include the lubricant's viscosity, temperature, surface roughness, and load, all of which affect the thickness and stability of the lubricant film. Optimal lubrication hinges on balancing these parameters to maintain a hydrodynamic or mixed lubrication regime, thereby enhancing performance and component lifespan.

Factors Affecting Kinetic Friction

Kinetic friction between two surfaces depends primarily on the nature of the materials in contact, surface roughness, and the presence of lubricants that reduce direct asperity interaction. Lubricated friction occurs when a lubricant film separates the surfaces, significantly lowering energy loss by minimizing adhesive forces and surface wear. Variables such as lubricant viscosity, surface temperature, and load pressure critically influence the coefficient of kinetic friction in lubricated systems.

Real-World Applications of Lubricated Friction

Lubricated friction significantly reduces wear and heat generation in machinery by introducing a lubricant layer that separates moving surfaces, enhancing efficiency in automotive engines, industrial gearboxes, and hydraulic systems. This reduction in friction minimizes energy loss and extends the operational lifespan of mechanical components, crucial in high-speed and high-load environments such as aerospace turbines and manufacturing equipment. Real-world applications rely on specialized lubricants tailored to operating conditions, ensuring optimal performance and protection against corrosion and contamination.

Real-World Examples of Kinetic Friction

Kinetic friction occurs when two surfaces slide past each other, such as a car's tires skidding on a wet road or a hockey puck gliding across ice. Lubricated friction, by contrast, reduces resistance through a layer of lubricant, commonly seen in engine oil minimizing wear between piston and cylinder walls. Real-world examples of kinetic friction highlight its significance in everyday activities, including the drag force on conveyor belts and the braking force exerted by bicycle brakes on wheel rims.

Comparative Analysis: Efficiency and Performance

Lubricated friction significantly reduces the coefficient of friction compared to kinetic friction, resulting in lower energy loss and enhanced mechanical efficiency. In machinery, lubricated surfaces minimize wear and heat generation, extending component lifespan and maintaining consistent performance under dynamic conditions. Kinetic friction, characterized by higher resistance and more rapid surface degradation, leads to increased energy consumption and decreased overall system efficiency.

Summary and Future Perspectives on Friction Control

Lubricated friction reduces kinetic friction by introducing a fluid layer that minimizes direct surface contact, leading to lower wear and energy loss in mechanical systems. Advances in nanotechnology and smart lubricants promise enhanced friction control through adaptive, self-healing layers that respond to changing operational conditions. Future research aims to integrate real-time monitoring with friction modulation to optimize performance and extend the lifespan of machinery in automotive, aerospace, and manufacturing industries.

Lubricated friction Infographic

libterm.com

libterm.com