Creep is the slow, permanent deformation of materials under constant stress, critical in engineering applications where long-term durability matters. Understanding how creep affects metals, polymers, and ceramics ensures safer design and prevents structural failures. Explore the article to learn how you can identify, measure, and mitigate creep in your materials.

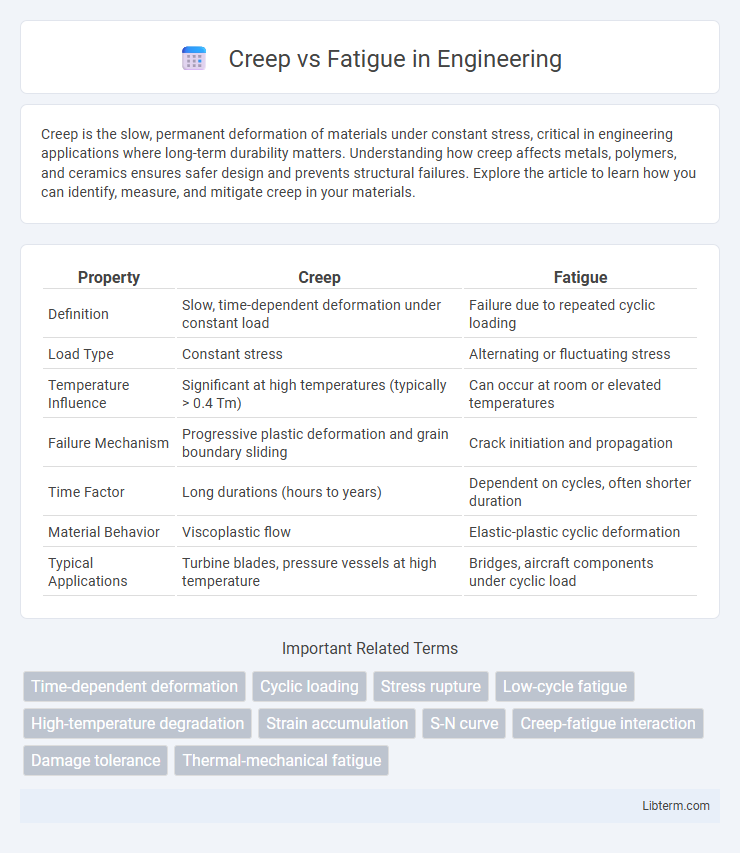

Table of Comparison

| Property | Creep | Fatigue |

|---|---|---|

| Definition | Slow, time-dependent deformation under constant load | Failure due to repeated cyclic loading |

| Load Type | Constant stress | Alternating or fluctuating stress |

| Temperature Influence | Significant at high temperatures (typically > 0.4 Tm) | Can occur at room or elevated temperatures |

| Failure Mechanism | Progressive plastic deformation and grain boundary sliding | Crack initiation and propagation |

| Time Factor | Long durations (hours to years) | Dependent on cycles, often shorter duration |

| Material Behavior | Viscoplastic flow | Elastic-plastic cyclic deformation |

| Typical Applications | Turbine blades, pressure vessels at high temperature | Bridges, aircraft components under cyclic load |

Understanding Creep and Fatigue: Key Differences

Creep refers to the time-dependent, permanent deformation of materials under constant stress at high temperature, while fatigue involves the progressive structural damage due to cyclic loading. Understanding the key differences involves recognizing that creep primarily occurs under sustained load over long periods, whereas fatigue failure results from repeated stress variations even at lower magnitudes. Material properties such as stress level, temperature, and loading frequency critically influence the mechanisms and lifespan associated with creep and fatigue phenomena.

Defining Creep: Causes and Characteristics

Creep is the gradual, time-dependent deformation of materials exposed to constant stress at elevated temperatures, primarily caused by atomic diffusion and dislocation motion within the material's microstructure. This phenomenon is characterized by three distinct stages: primary creep (decelerating strain rate), secondary or steady-state creep (constant strain rate), and tertiary creep (accelerating strain rate leading to failure). Understanding creep behavior is essential for designing components in high-temperature environments such as turbines, boilers, and aerospace engines.

Defining Fatigue: Process and Mechanisms

Fatigue refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, resulting in crack initiation and propagation. The process involves repeated stress fluctuations that lead to microstructural changes such as dislocation movement, grain boundary weakening, and accumulation of plastic strain. Mechanisms of fatigue include crack nucleation at stress concentrators, crack growth under cyclic stresses, and eventual fracture when the crack reaches a critical size.

Material Behavior Under Creep vs. Fatigue

Creep involves the time-dependent deformation of materials under a constant load at elevated temperatures, leading to gradual elongation and potential failure over prolonged periods. Fatigue refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, causing crack initiation and propagation even below the yield strength. Understanding the distinct mechanisms of atomic diffusion in creep and crack nucleation in fatigue is crucial for predicting material lifespan and optimizing engineering designs for high-stress and high-temperature environments.

Temperature and Stress Effects in Creep and Fatigue

Temperature significantly accelerates creep deformation by enhancing atomic diffusion and dislocation movement, causing materials to experience progressive elongation under constant stress. Stress levels in creep influence the rate of strain accumulation, with higher stresses intensifying creep strain and reducing material lifespan. In fatigue, cyclic stress fluctuates the material's microstructure, leading to crack initiation and propagation, while elevated temperatures generally decrease fatigue strength by promoting oxidation and microstructural changes that accelerate crack growth.

Common Applications Affected by Creep and Fatigue

Creep commonly affects high-temperature applications such as turbine blades in jet engines, boilers, and nuclear reactors, where long-term exposure to stress and heat causes gradual deformation. Fatigue primarily impacts components subjected to cyclic loading, including aircraft wings, bridges, and automotive suspension systems, leading to crack initiation and failure over repeated stress cycles. Both phenomena are critical in materials selection and design for ensuring durability and safety in aerospace, power generation, and structural engineering industries.

Detection and Measurement Techniques

Creep detection primarily relies on high-temperature strain gauges, extensometers, and thermomechanical analyzers to monitor time-dependent deformation under constant stress, often supplemented by digital image correlation for precise displacement tracking. Fatigue measurement techniques emphasize cyclic loading tests using strain-controlled fatigue test machines, acoustic emission sensors to capture crack initiation, and scanning electron microscopy for micro-crack analysis post-testing. Advanced methods like infrared thermography and X-ray computed tomography enhance both creep and fatigue evaluation by enabling non-destructive internal damage assessment and real-time monitoring.

Prevention and Mitigation Strategies

Implementing controlled environmental conditions and selecting materials with high resistance to deformation effectively prevent creep in high-temperature applications. Fatigue mitigation relies on optimizing design to reduce stress concentrations and applying surface treatments such as shot peening to enhance material durability. Regular maintenance and non-destructive testing enable early detection of creep and fatigue damage, reducing the risk of catastrophic failure.

Real-World Case Studies: Creep vs. Fatigue Failures

Real-world case studies reveal that creep failures predominantly occur in high-temperature environments such as gas turbines and power plant boilers, where materials experience prolonged stress leading to gradual deformation. Fatigue failures are common in aerospace components and automotive parts subjected to cyclic loading, causing crack initiation and propagation over time. Analyzing these failures enables engineers to select materials and design strategies that mitigate risks associated with specific operational stresses.

Conclusion: Selecting Materials for Enhanced Durability

Selecting materials for enhanced durability requires evaluating both creep and fatigue properties to ensure long-term performance under varying stress and temperature conditions. Materials with high creep resistance maintain structural integrity during prolonged exposure to elevated temperatures, while superior fatigue resistance prevents failure from repeated cyclic loading. Balancing these characteristics through advanced alloys or composites optimizes lifespan and reliability in demanding engineering applications.

Creep Infographic

libterm.com

libterm.com