Plug valves provide reliable and efficient control of fluid flow in various industrial applications, featuring a cylindrical or tapered plug that rotates inside the valve body to open or close the passage. Their simple design allows for quick operation and minimal maintenance, making them ideal for handling abrasive or corrosive fluids. Explore the rest of the article to learn how plug valves can optimize your system's performance and durability.

Table of Comparison

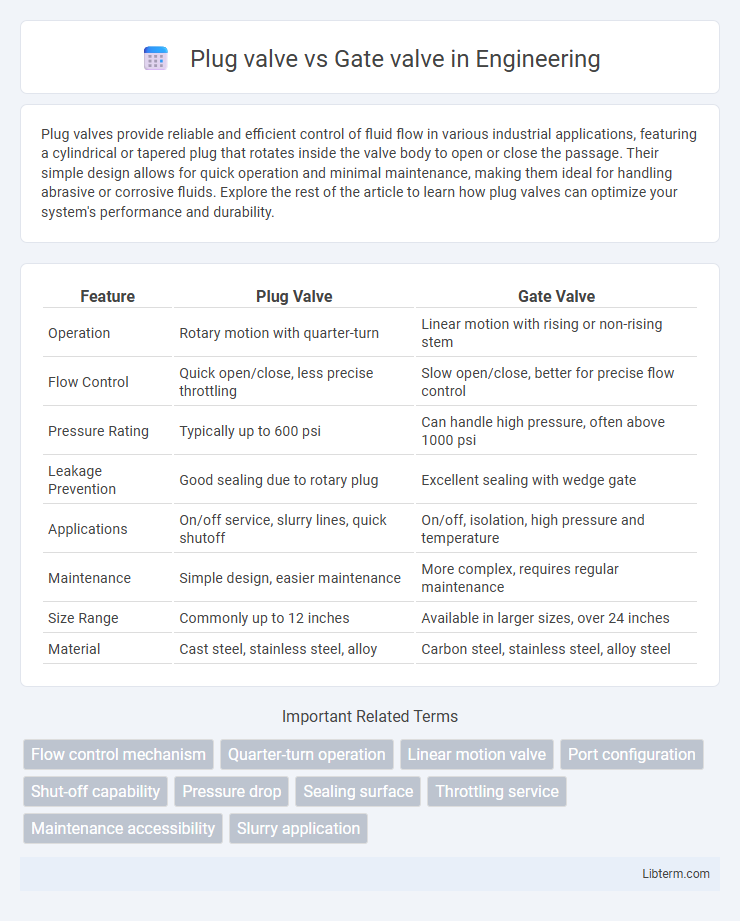

| Feature | Plug Valve | Gate Valve |

|---|---|---|

| Operation | Rotary motion with quarter-turn | Linear motion with rising or non-rising stem |

| Flow Control | Quick open/close, less precise throttling | Slow open/close, better for precise flow control |

| Pressure Rating | Typically up to 600 psi | Can handle high pressure, often above 1000 psi |

| Leakage Prevention | Good sealing due to rotary plug | Excellent sealing with wedge gate |

| Applications | On/off service, slurry lines, quick shutoff | On/off, isolation, high pressure and temperature |

| Maintenance | Simple design, easier maintenance | More complex, requires regular maintenance |

| Size Range | Commonly up to 12 inches | Available in larger sizes, over 24 inches |

| Material | Cast steel, stainless steel, alloy | Carbon steel, stainless steel, alloy steel |

Introduction to Plug Valves and Gate Valves

Plug valves feature a cylindrical or conically tapered plug with a through passage, enabling quick quarter-turn operation to control fluid flow. Gate valves utilize a sliding gate mechanism that moves vertically to start or stop flow, providing tight sealing for on/off service. Both valve types are essential in pipeline systems, with plug valves preferred for rapid operation and gate valves selected for minimal pressure drop and full bore flow.

Design and Construction Differences

Plug valves feature a cylindrical or conically tapered plug that rotates within the valve body to control flow, offering a straightforward quarter-turn operation and compact design. Gate valves utilize a flat or wedge-shaped gate that moves vertically to start or stop flow, typically requiring multiple turns to operate and a larger body to accommodate the gate mechanism. The plug valve's design emphasizes quick operation and minimal flow resistance, while gate valves are engineered for full flow with minimal pressure drop when fully open.

Operational Mechanism Comparison

Plug valves operate by rotating a cylindrical or tapered plug within the valve body to control flow, providing quick quarter-turn operation and minimal pressure drop. Gate valves utilize a wedge-shaped gate that moves vertically between two seats to start or stop flow, offering excellent shutoff but slower operation due to linear movement. The plug valve's design allows for rapid flow direction changes, while gate valves are better suited for fully open or closed positions with minimal leakage.

Seal Performance and Leak Prevention

Plug valves offer superior seal performance due to their tapered or cylindrical plugs that compress against the valve body, creating a tight seal that effectively prevents leaks in high-pressure applications. Gate valves rely on a wedge-shaped gate that slides into place, which may result in minor leakage if debris prevents a full seal, making them less reliable in leak prevention compared to plug valves. For critical applications demanding robust leak prevention and consistent sealing, plug valves are generally preferred due to their design and seal integrity.

Pressure and Temperature Suitability

Plug valves are typically suitable for moderate pressure and temperature applications, offering reliable operation up to around 600 psi and temperatures up to 400degF, making them ideal for low to medium pressure systems. Gate valves excel in high-pressure and high-temperature environments, often rated for pressures exceeding 1000 psi and temperatures above 600degF, which ensures durability and optimal sealing in demanding industrial settings. Choosing between plug and gate valves depends on specific system requirements related to pressure tolerance and temperature resistance to ensure safety and efficiency.

Flow Control Capabilities

Plug valves provide rapid on/off flow control with minimal pressure drop, making them ideal for applications requiring quick valve operation and tight shut-off. Gate valves offer precise throttling capabilities and gradual flow regulation, which suits systems where flow control accuracy is critical. Flow control efficiency in plug valves excels in low-pressure systems, whereas gate valves perform optimally in high-pressure environments requiring fine adjustments.

Maintenance and Durability Considerations

Plug valves require minimal maintenance due to their simple design and fewer moving parts, reducing the likelihood of wear and tear. Gate valves, with more complex mechanisms and sliding gate components, demand regular lubrication and inspection to prevent leakage and operational failure. Durability in plug valves excels in applications with frequent operation, while gate valves are better suited for low-cycle environments where consistent sealing over time is critical.

Typical Applications in Industry

Plug valves are commonly used in industries requiring quick and reliable shut-off for gas and liquid flow, such as chemical processing and oil and gas pipelines, due to their simple quarter-turn operation and minimal leakage. Gate valves excel in applications where full flow and minimal pressure drop are critical, including water treatment plants, power generation, and petrochemical plants, offering a tight seal and suitability for high-pressure environments. Both valves serve crucial roles in industrial fluid control, with plug valves favored for rapid switching and gate valves selected for isolation in steady flow systems.

Cost and Installation Factors

Plug valves generally offer lower initial costs and simpler installation due to their compact design and fewer components, making them suitable for tight spaces and quick setups. Gate valves tend to have higher costs associated with their more complex structure and heavier materials, often requiring more extensive installation efforts and maintenance. Cost efficiency in plug valves is favored in applications with frequent operation, while gate valves are preferred for full-flow applications despite the higher investment.

Choosing Between Plug and Gate Valves

Choosing between plug valves and gate valves depends on factors like flow control precision, maintenance frequency, and application type. Plug valves offer quick quarter-turn operation and are ideal for on/off service with minimal pressure drop, while gate valves provide precise throttling and are better suited for full open or close positions in high-pressure systems. Material compatibility, installation space, and cost also influence the selection process to ensure optimal valve performance and longevity.

Plug valve Infographic

libterm.com

libterm.com