A duplex is a residential building divided into two separate living units, often sharing a common wall while offering private entrances and amenities. This housing option provides an ideal balance between affordability and privacy, making it appealing for families, investors, and those seeking rental income opportunities. Discover more about the benefits, design considerations, and investment potential of duplexes in the rest of this article.

Table of Comparison

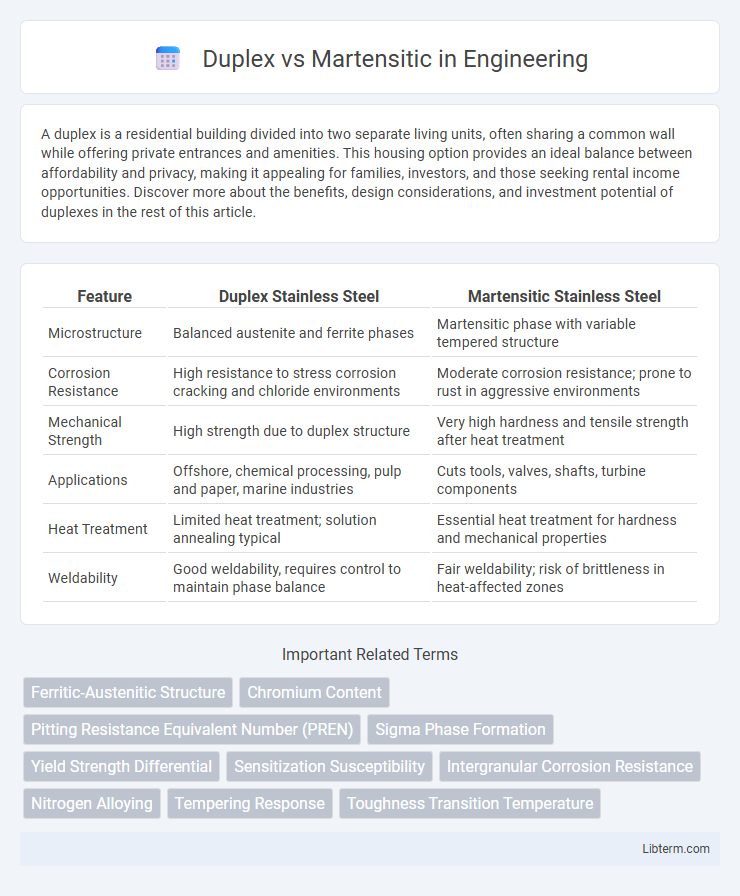

| Feature | Duplex Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Microstructure | Balanced austenite and ferrite phases | Martensitic phase with variable tempered structure |

| Corrosion Resistance | High resistance to stress corrosion cracking and chloride environments | Moderate corrosion resistance; prone to rust in aggressive environments |

| Mechanical Strength | High strength due to duplex structure | Very high hardness and tensile strength after heat treatment |

| Applications | Offshore, chemical processing, pulp and paper, marine industries | Cuts tools, valves, shafts, turbine components |

| Heat Treatment | Limited heat treatment; solution annealing typical | Essential heat treatment for hardness and mechanical properties |

| Weldability | Good weldability, requires control to maintain phase balance | Fair weldability; risk of brittleness in heat-affected zones |

Introduction to Duplex and Martensitic Stainless Steels

Duplex stainless steels exhibit a balanced microstructure of approximately 50% austenite and 50% ferrite, combining excellent corrosion resistance and high strength, making them ideal for chemical processing and offshore applications. Martensitic stainless steels are characterized by a primarily martensitic microstructure, providing superior hardness and wear resistance, commonly used in tools, knives, and aerospace components. Both types offer distinct mechanical and chemical properties tailored to specific industrial demands, with duplex steels excelling in toughness and corrosion resistance, while martensitic steels emphasize strength and machinability.

Chemical Composition Differences

Duplex stainless steels contain approximately 18-28% chromium, 4-6% nickel, and 3-5% molybdenum, with a balanced mixture of austenite and ferrite phases, enhancing corrosion resistance and strength. Martensitic stainless steels typically include 11-17% chromium, low nickel (usually below 1%), and minimal molybdenum, featuring a primarily martensitic microstructure that allows for high hardness and wear resistance. The higher nickel and molybdenum content in duplex steels significantly improve their pitting and crevice corrosion resistance compared to martensitic grades.

Microstructure Comparison

Duplex stainless steel features a balanced microstructure of approximately 50% austenite and 50% ferrite, providing a combination of high strength and excellent corrosion resistance. Martensitic stainless steel exhibits a predominantly martensitic microstructure, formed through rapid cooling that enhances hardness and wear resistance but reduces toughness. The coexistence of dual phases in duplex steels offers superior resistance to stress corrosion cracking compared to the single-phase martensitic structure.

Mechanical Properties Overview

Duplex stainless steel exhibits a balanced microstructure of austenite and ferrite, resulting in higher tensile strength typically around 700-900 MPa and excellent toughness compared to martensitic stainless steel, which has tensile strength ranging from 800-1200 MPa but lower ductility. Martensitic stainless steel offers superior hardness and wear resistance due to its fully martensitic structure but is more prone to brittleness and lower corrosion resistance. Duplex stainless steel provides better fatigue resistance and stress corrosion cracking resistance, making it suitable for demanding structural applications.

Corrosion Resistance Capabilities

Duplex stainless steel exhibits superior corrosion resistance due to its balanced austenitic and ferritic microstructure, providing excellent resistance to chloride-induced pitting and stress corrosion cracking. Martensitic stainless steel, while strong and hard, offers lower corrosion resistance, particularly in aggressive environments rich in chlorides or acids. Duplex grades are preferred for applications demanding enhanced durability in marine and chemical processing industries where corrosion resistance is critical.

Common Industrial Applications

Duplex stainless steel is commonly used in chemical processing, oil and gas pipelines, and marine applications due to its excellent corrosion resistance and high strength. Martensitic stainless steel is favored for manufacturing blades, cutting tools, and valves because of its hardness and wear resistance. Both materials serve critical roles in industries requiring durability and specific mechanical properties.

Weldability and Fabrication Considerations

Duplex stainless steel offers superior weldability compared to martensitic stainless steel due to its balanced microstructure of austenite and ferrite, which reduces the risk of cracking during welding. Martensitic grades require careful preheating and post-weld heat treatment to prevent hardness-related brittleness and stress concentration. Fabrication of duplex steel benefits from faster welding speeds and less distortion, while martensitic steel demands slower cooling rates and controlled welding parameters to maintain mechanical integrity.

Cost and Availability

Duplex stainless steel offers moderate cost with better corrosion resistance and higher availability in various thicknesses compared to martensitic grades, which are generally less expensive but less commonly stocked due to their specialized applications. Martensitic stainless steel is often chosen for its hardness and wear resistance, but its limited availability can increase lead times and costs for custom sizes. Cost-efficiency depends on application needs, where duplex provides balanced performance and availability, while martensitic is preferred for specific, high-strength uses.

Performance in Extreme Conditions

Duplex stainless steel offers superior corrosion resistance and excellent mechanical strength in extreme conditions, including high chloride and acidic environments, making it ideal for offshore and chemical processing applications. Martensitic stainless steel excels in hardness and wear resistance due to its high carbon content, providing reliable performance under high stress and abrasion conditions such as in aerospace and tooling industries. Duplex grades balance toughness and durability, while martensitic steels prioritize hardness and strength for demanding operational environments.

Choosing the Right Stainless Steel for Your Needs

Duplex stainless steel combines austenitic and ferritic properties, offering superior corrosion resistance and strength suitable for chemical processing and marine applications. Martensitic stainless steel provides high hardness and wear resistance, ideal for cutlery, turbines, and structural components requiring durability. Selecting between duplex and martensitic depends on balancing the need for corrosion resistance versus mechanical strength in your specific environment.

Duplex Infographic

libterm.com

libterm.com