Simulation testing evaluates the performance and reliability of systems under controlled, virtual conditions to identify potential issues before real-world deployment. It uses realistic scenarios to replicate operational challenges, ensuring accuracy and efficiency in the final product. Explore the article to discover how simulation testing can enhance your development process and prevent costly errors.

Table of Comparison

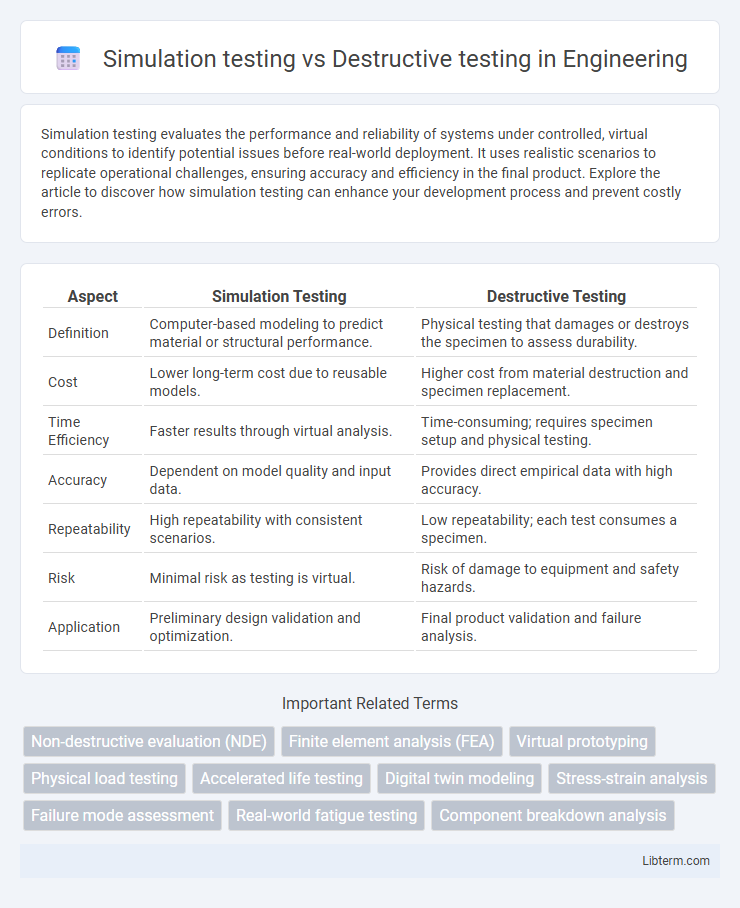

| Aspect | Simulation Testing | Destructive Testing |

|---|---|---|

| Definition | Computer-based modeling to predict material or structural performance. | Physical testing that damages or destroys the specimen to assess durability. |

| Cost | Lower long-term cost due to reusable models. | Higher cost from material destruction and specimen replacement. |

| Time Efficiency | Faster results through virtual analysis. | Time-consuming; requires specimen setup and physical testing. |

| Accuracy | Dependent on model quality and input data. | Provides direct empirical data with high accuracy. |

| Repeatability | High repeatability with consistent scenarios. | Low repeatability; each test consumes a specimen. |

| Risk | Minimal risk as testing is virtual. | Risk of damage to equipment and safety hazards. |

| Application | Preliminary design validation and optimization. | Final product validation and failure analysis. |

Understanding Simulation Testing

Simulation testing uses virtual models and computer algorithms to replicate real-world conditions, enabling the assessment of product behavior without physical damage. This method supports iterative design improvements and cost-effective risk analysis by predicting performance outcomes under various scenarios. In contrast, destructive testing physically pushes materials or components to failure, providing concrete data on strength and durability but eliminating the tested sample.

Defining Destructive Testing

Destructive testing involves subjecting materials or components to conditions that cause failure to evaluate their performance, durability, and safety limits. This method provides precise data on breaking points, structural weaknesses, and lifecycle expectancy by analyzing physical damage after stress application. In contrast, simulation testing uses virtual models to predict behavior under various scenarios without physical damage, offering cost-effective and non-invasive analysis.

Key Differences Between Simulation and Destructive Testing

Simulation testing uses virtual models to predict product behavior under various conditions without causing damage, enabling cost-effective and fast analysis. Destructive testing involves physically pushing materials or products to failure to assess durability and safety, providing real-world performance data but at higher costs and time consumption. Simulation testing offers repeatability and scalability, whereas destructive testing provides conclusive proof of material limits and compliance with safety standards.

Advantages of Simulation Testing

Simulation testing offers significant advantages over destructive testing by enabling extensive analysis without damaging the actual product, reducing costs associated with physical prototypes and material waste. It allows for rapid iterations and testing of multiple scenarios under varied conditions, improving design accuracy and performance optimization. The ability to collect detailed data in a controlled virtual environment supports better decision-making and accelerates development cycles.

Benefits of Destructive Testing

Destructive testing provides precise insights into material strength and failure points, ensuring product safety and reliability under extreme conditions. It enables manufacturers to identify weaknesses and comply with industry standards, reducing costly field failures and recalls. This testing method uncovers critical data that simulation testing may overlook, offering a concrete basis for improving design and manufacturing processes.

Limitations of Simulation Testing

Simulation testing often struggles with accurately replicating complex real-world conditions, leading to potential discrepancies between predicted and actual performance outcomes. It can fail to capture unforeseen material failures or environmental variables that destructive testing inherently exposes. High-fidelity simulations require extensive computational resources and detailed input data, limiting their practical application in some scenarios.

Drawbacks of Destructive Testing

Destructive testing often results in the complete loss of the test sample, leading to increased costs and material waste, especially when testing expensive or limited-quantity components. This method can be time-consuming since each test destroys the specimen, requiring multiple samples for comprehensive analysis, which is not always feasible. Unlike simulation testing, destructive testing cannot provide real-time data or assess the performance of a part in operational conditions without causing failure.

Cost Implications: Simulation vs Destructive Testing

Simulation testing significantly reduces costs by eliminating the need for physical prototypes and minimizing material waste, making it ideal for iterative design cycles. Destructive testing incurs higher expenses due to the consumption of actual products and the requirement for multiple samples to ensure accurate results. Companies must weigh the upfront investment in simulation software against the ongoing material and labor costs associated with destructive testing methods.

Industry Applications for Each Testing Method

Simulation testing enables industries such as aerospace and automotive to predict product performance under various conditions without causing physical damage, reducing costs and development time. Destructive testing, frequently used in construction and materials manufacturing sectors, provides critical data on product strength and failure points by intentionally pushing materials to breaking limits. Both testing methods are essential for ensuring safety, durability, and regulatory compliance across diverse industrial applications.

Choosing the Right Testing Approach

Selecting the appropriate testing approach depends on the product's lifecycle stage, budget constraints, and safety requirements. Simulation testing offers a cost-effective and rapid way to predict performance and identify potential failures without damaging prototypes, ideal for early design phases. Destructive testing provides definitive data on material limits and product durability by physically pushing products to failure, essential for final validation and regulatory compliance.

Simulation testing Infographic

libterm.com

libterm.com