Induction motors are widely used in industrial and household applications due to their robust construction, reliability, and efficiency. They operate on the principle of electromagnetic induction, where the stator creates a rotating magnetic field that induces current in the rotor, causing it to turn. Explore the rest of the article to understand how an induction motor works and its practical benefits for your projects.

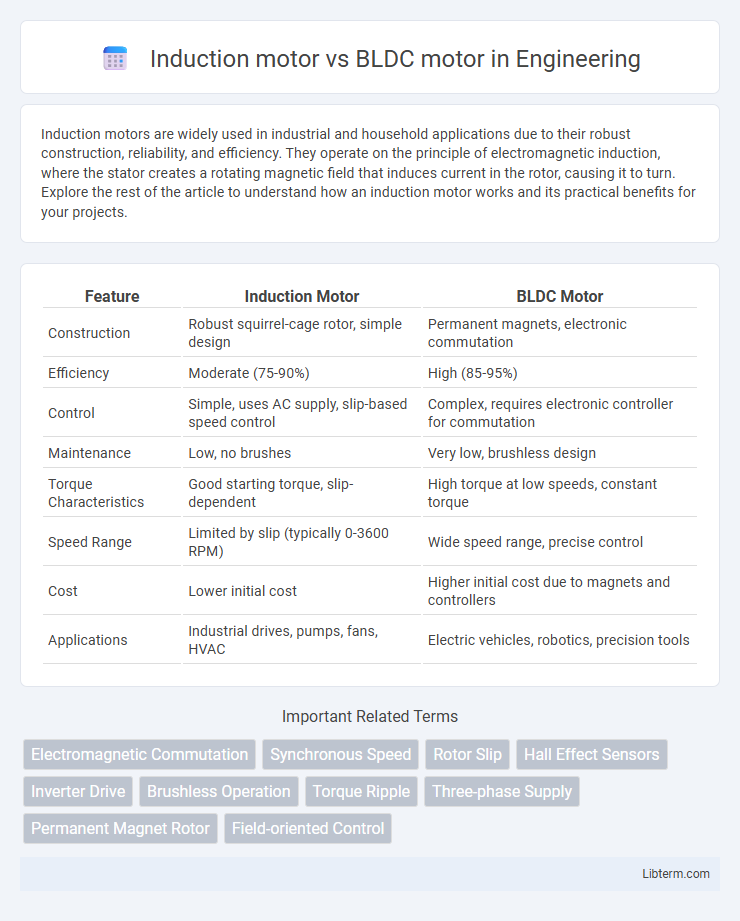

Table of Comparison

| Feature | Induction Motor | BLDC Motor |

|---|---|---|

| Construction | Robust squirrel-cage rotor, simple design | Permanent magnets, electronic commutation |

| Efficiency | Moderate (75-90%) | High (85-95%) |

| Control | Simple, uses AC supply, slip-based speed control | Complex, requires electronic controller for commutation |

| Maintenance | Low, no brushes | Very low, brushless design |

| Torque Characteristics | Good starting torque, slip-dependent | High torque at low speeds, constant torque |

| Speed Range | Limited by slip (typically 0-3600 RPM) | Wide speed range, precise control |

| Cost | Lower initial cost | Higher initial cost due to magnets and controllers |

| Applications | Industrial drives, pumps, fans, HVAC | Electric vehicles, robotics, precision tools |

Introduction to Induction Motors and BLDC Motors

Induction motors operate based on electromagnetic induction where the stator's rotating magnetic field induces current in the rotor, making them robust and widely used in industrial applications. Brushless DC (BLDC) motors utilize electronic commutation and permanent magnets on the rotor, offering higher efficiency, precise speed control, and reduced maintenance compared to induction motors. The choice between induction motors and BLDC motors depends on application-specific requirements like efficiency, torque density, and control complexity.

Working Principle: Induction vs. BLDC Motors

Induction motors operate based on electromagnetic induction, where a rotating magnetic field in the stator induces current in the rotor, producing torque through interaction between the stator's magnetic field and rotor currents. Brushless DC (BLDC) motors utilize electronically commutated permanent magnets on the rotor and stator windings energized in sequence by a controller to generate continuous rotation. The main difference lies in induction motors relying on induced current for rotor movement, whereas BLDC motors use direct electronic control of stator fields to achieve precise torque and speed control.

Construction Differences

Induction motors feature a squirrel-cage rotor and stator winding, relying on electromagnetic induction to generate rotor current, while BLDC motors have permanent magnets on the rotor and a stator equipped with electronic commutation coils. The absence of brushes in BLDC motors eliminates mechanical wear, enabling higher efficiency and smoother operation compared to the slip rings or brushes found in some induction motor variants. BLDC motors' compact design and precise control electronics contrast with the more robust and simpler construction of induction motors, influencing applications and maintenance requirements.

Efficiency and Performance Comparison

BLDC motors exhibit higher efficiency, often exceeding 85-90%, due to their permanent magnets and electronic commutation, which reduce energy losses compared to induction motors, typically ranging from 75-85%. In terms of performance, BLDC motors provide superior torque-to-weight ratio, faster acceleration, and precise speed control, making them ideal for applications requiring high dynamic response. Induction motors, while generally bulkier and less efficient, offer robustness, lower cost, and simpler maintenance, suitable for heavy-duty industrial use where efficiency is less critical.

Speed Control and Torque Characteristics

Induction motors exhibit variable speed control primarily through voltage and frequency adjustments using variable frequency drives (VFDs), offering robust torque at low speeds but with some slip-related losses. BLDC motors provide precise speed control via electronic commutation and maintain high torque over a wide speed range with better efficiency and reduced heat generation. The torque ripple is minimal in BLDC motors, enhancing smooth operation compared to the higher starting torque and robustness of induction motors under heavy loads.

Cost Analysis: Initial and Maintenance

Induction motors generally have a lower initial cost due to simpler construction and widespread availability of materials, making them more economical for high-power applications. BLDC motors tend to have higher upfront costs because of rare-earth magnets and complex electronic controllers but benefit from lower maintenance expenses due to brushless operation and enhanced efficiency. Over the motor's lifespan, the reduced maintenance and energy savings of BLDC motors can offset the higher initial investment, especially in precision and energy-critical applications.

Applications in Industry and Everyday Life

Induction motors are widely used in industrial applications such as pumps, compressors, conveyors, and HVAC systems due to their robustness, low cost, and ability to operate in harsh environments. BLDC motors find extensive use in everyday life applications including electric vehicles, drones, household appliances, and computer cooling fans because of their high efficiency, low maintenance, and precise speed control. Industries benefit from induction motors for heavy-duty constant-speed tasks, while BLDC motors excel in scenarios needing variable speed and energy-efficient operations.

Advantages of Induction Motors

Induction motors offer robust construction, making them highly durable and suitable for harsh industrial environments. They provide high efficiency and reliable performance with less maintenance due to the absence of brushes and commutators. Their cost-effectiveness and ability to operate on standard AC power supply make them ideal for a wide range of applications.

Advantages of BLDC Motors

BLDC motors offer higher efficiency and better speed-torque characteristics compared to induction motors, resulting in reduced energy consumption and improved performance. Their maintenance requirements are significantly lower due to the absence of brushes, enhancing reliability and operational lifespan. BLDC motors also provide precise control and quieter operation, making them ideal for applications demanding high accuracy and reduced noise levels.

Choosing the Right Motor: Key Considerations

Selecting the right motor between an induction motor and a BLDC motor depends on factors such as efficiency, control complexity, and application requirements. Induction motors offer robustness and cost-effectiveness in high-power industrial settings, while BLDC motors provide superior efficiency, precise speed control, and reduced maintenance for applications like electric vehicles and robotics. Key considerations include operational environment, desired torque-speed characteristics, and overall system integration for optimal performance.

Induction motor Infographic

libterm.com

libterm.com