Vickers hardness measures a material's resistance to indentation using a diamond pyramid-shaped indenter, providing precise hardness values applicable to metals and ceramics. This test is crucial for assessing material wear resistance and mechanical properties, ensuring quality in manufacturing and engineering processes. Explore the rest of the article to understand how Vickers hardness can impact your material selection and testing methods.

Table of Comparison

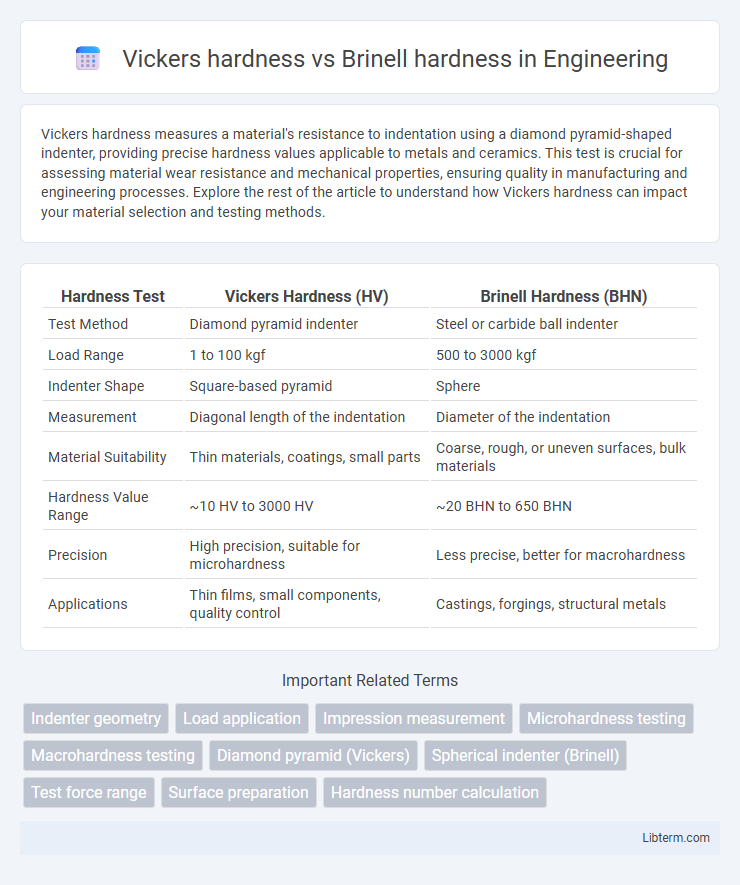

| Hardness Test | Vickers Hardness (HV) | Brinell Hardness (BHN) |

|---|---|---|

| Test Method | Diamond pyramid indenter | Steel or carbide ball indenter |

| Load Range | 1 to 100 kgf | 500 to 3000 kgf |

| Indenter Shape | Square-based pyramid | Sphere |

| Measurement | Diagonal length of the indentation | Diameter of the indentation |

| Material Suitability | Thin materials, coatings, small parts | Coarse, rough, or uneven surfaces, bulk materials |

| Hardness Value Range | ~10 HV to 3000 HV | ~20 BHN to 650 BHN |

| Precision | High precision, suitable for microhardness | Less precise, better for macrohardness |

| Applications | Thin films, small components, quality control | Castings, forgings, structural metals |

Introduction to Hardness Testing Methods

Vickers hardness and Brinell hardness are critical methods used in material science to quantify the resistance of materials to deformation. Vickers hardness testing employs a diamond pyramid-shaped indenter, providing precise measurements on small or thin samples, making it ideal for fine microstructural analysis. In contrast, Brinell hardness testing uses a larger steel or tungsten carbide ball indenter to assess coarse-grained materials or larger surfaces, offering an averaged hardness value that reflects the material's bulk properties.

Overview of Vickers Hardness Test

The Vickers hardness test measures a material's hardness by pressing a diamond-shaped indenter with a specific load onto the surface and calculating hardness from the size of the resulting indentation. It provides precise and consistent results, suitable for testing thin materials and small parts, unlike the Brinell test which uses a larger steel ball indenter. Vickers hardness values are applicable across a wide range of materials, enabling detailed hardness comparisons in metals, ceramics, and composites.

Overview of Brinell Hardness Test

The Brinell Hardness Test measures material hardness by pressing a hard steel or carbide ball into the surface under a fixed load and calculating hardness based on the indentation's diameter. It is widely used for testing metals with coarse structures or rough surfaces, providing an average hardness value over a larger area compared to the Vickers test. This method excels in evaluating castings and forgings, where surface irregularities can affect smaller indentation tests.

Fundamental Principles Compared

Vickers hardness is determined by measuring the diagonal length of a square-shaped indentation made by a diamond pyramid indenter under a specific load, offering precise hardness values suitable for thin materials and small parts. Brinell hardness uses a hard steel or tungsten carbide ball indenter to create a circular indentation, calculating hardness based on the load divided by the surface area of the indentation, making it ideal for testing coarse materials and heterogeneous surfaces. Both methods quantify resistance to plastic deformation but differ fundamentally in indentor shape, indentation geometry, and application scope, affecting their resolution and material compatibility.

Indenter Types and Testing Procedures

Vickers hardness testing employs a diamond pyramid-shaped indenter with a square base and an angle of 136 degrees between opposite faces, providing precise measurements for thin materials and small parts. Brinell hardness testing uses a hardened steel or carbide ball indenter, typically 10 mm in diameter, which is pressed into the material under a specified load, suitable for measuring coarse-grained or heterogeneous materials. The Vickers test applies a smaller load and measures the diagonal of the indentation microscopically, while the Brinell test uses larger loads and measures the diameter of the indentation optically to calculate hardness.

Sample Preparation and Testing Conditions

Vickers hardness testing requires precise surface preparation with a smooth, polished sample to ensure accurate indentation measurements using a diamond pyramid indenter under controlled loads, typically ranging from 1 to 100 kgf. Brinell hardness testing involves a larger steel or carbide ball indenter and requires samples with flat, smooth surfaces to avoid indenter slippage, with test loads usually between 500 to 3000 kgf applied for consistent indentation diameters. Both methods demand strict control over testing conditions such as load duration, surface cleanliness, and sample mounting to minimize variability and enhance repeatability of hardness values.

Measurement Accuracy and Precision

Vickers hardness testing utilizes a diamond indenter producing small, precise indentations ideal for measuring thin materials and coatings with high resolution, resulting in greater accuracy and repeatability compared to Brinell hardness. Brinell hardness employs a larger steel or tungsten carbide ball indenter, which can cause surface deformations and less defined impressions, leading to potentially lower measurement precision on heterogeneous or thin samples. Overall, Vickers hardness offers superior measurement accuracy and precision for micro-scale hardness assessments, whereas Brinell is more suited for coarse materials with less stringent requirements.

Applications and Suitability for Materials

Vickers hardness testing is ideal for measuring very small, thin, or hard materials such as thin films, coatings, and microstructures due to its use of a diamond indenter and precise load control. Brinell hardness testing suits larger, coarse-grained, or heterogeneous materials like castings and forgings, where an average hardness value over a larger surface area is beneficial. Applications requiring detailed hardness profiles for microengineering favor Vickers, while Brinell is preferred in construction and heavy machinery industries for evaluating bulk material resistance.

Advantages and Limitations of Each Method

Vickers hardness testing offers high accuracy and versatility for measuring microhardness on thin materials or small parts, with a precise diamond indenter that provides consistent results across a wide range of hardness values. Brinell hardness testing excels in evaluating coarse or rough materials, using a larger steel or carbide ball indenter that averages hardness over a broader surface area, making it suitable for materials with heterogeneous structures. However, the Vickers method is more sensitive to surface preparation and requires microscopy, limiting its use on rough surfaces, whereas Brinell testing is less precise on thin specimens and may produce indents too large for small components.

Choosing Between Vickers and Brinell Hardness Tests

Choosing between Vickers and Brinell hardness tests depends on the material type and the required measurement precision. Vickers hardness test is ideal for thin materials, coatings, and small parts due to its small indentation size and high accuracy across a wide hardness range. Brinell hardness test suits larger, coarse-grained metals and castings where surface roughness and material heterogeneity require a larger indenter and load for representative hardness values.

Vickers hardness Infographic

libterm.com

libterm.com