Plain bearings provide smooth motion and reduce friction between moving parts using simple, durable surfaces without rolling elements. They are ideal for applications requiring low maintenance and can support heavy loads in compact spaces. Discover how plain bearings can enhance your machinery's performance in the rest of this article.

Table of Comparison

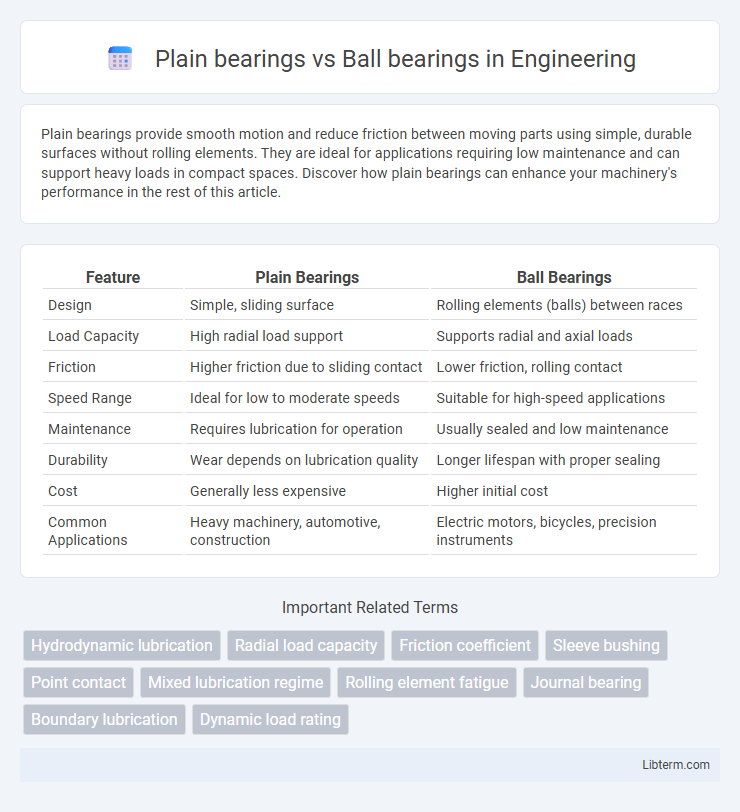

| Feature | Plain Bearings | Ball Bearings |

|---|---|---|

| Design | Simple, sliding surface | Rolling elements (balls) between races |

| Load Capacity | High radial load support | Supports radial and axial loads |

| Friction | Higher friction due to sliding contact | Lower friction, rolling contact |

| Speed Range | Ideal for low to moderate speeds | Suitable for high-speed applications |

| Maintenance | Requires lubrication for operation | Usually sealed and low maintenance |

| Durability | Wear depends on lubrication quality | Longer lifespan with proper sealing |

| Cost | Generally less expensive | Higher initial cost |

| Common Applications | Heavy machinery, automotive, construction | Electric motors, bicycles, precision instruments |

Introduction to Plain Bearings and Ball Bearings

Plain bearings, also known as sleeve or journal bearings, feature a simple, cylindrical design that supports rotational or sliding motion by providing a surface for contact between moving parts, typically made from materials like bronze, plastic, or composites. Ball bearings utilize spherical rolling elements placed between inner and outer races, significantly reducing friction and enabling smooth motion under radial and axial loads, commonly found in machinery and automotive applications. Both types of bearings serve critical roles in mechanical systems, with plain bearings favored for low-speed, high-load conditions and ball bearings preferred for high-speed, precision performance.

Key Differences Between Plain and Ball Bearings

Plain bearings use sliding motion to support loads and reduce friction, making them ideal for heavy loads and low-speed applications. Ball bearings utilize rolling elements to minimize friction and enhance rotational speed, offering better performance in high-speed and precision environments. Key differences include their friction type, load capacity, maintenance requirements, and suitability for specific operational conditions.

How Plain Bearings Work

Plain bearings function through a sliding motion between the shaft and the bearing surface, relying on a thin lubricating film to reduce friction and wear. These bearings distribute load over a larger surface area, providing high load capacity and durability in applications with oscillating or low-speed rotations. Unlike ball bearings, plain bearings do not use rolling elements, resulting in quieter operation and better performance in contaminated environments.

How Ball Bearings Operate

Ball bearings operate by utilizing a series of steel or ceramic balls placed between inner and outer metal rings, known as races. These balls reduce friction and support radial and axial loads by rolling smoothly, allowing rotational motion with minimal resistance and wear. This design enhances efficiency and precision in applications ranging from automotive wheels to industrial machinery.

Advantages of Plain Bearings

Plain bearings offer advantages such as lower friction loss and quieter operation compared to ball bearings. They provide superior load distribution and durability under heavy or shock loads, making them ideal for applications with high radial loads and low speed. Their simpler design and fewer moving parts also result in reduced maintenance requirements and longer service life.

Benefits of Ball Bearings

Ball bearings offer reduced friction and higher rotational speeds compared to plain bearings, making them ideal for applications requiring precision and efficiency. Their design minimizes wear and extends the lifespan of machinery by distributing loads evenly across the rolling elements. Enhanced performance under radial and axial loads, combined with lower maintenance requirements, positions ball bearings as a superior choice in high-speed and high-precision environments.

Common Applications of Plain Bearings

Plain bearings are commonly used in automotive engines, industrial machinery, and household appliances due to their simplicity and ability to handle high loads with low-speed motion. They excel in applications such as hinges, pivots, and shafts where lubrication is manageable and noise reduction is crucial. Unlike ball bearings, plain bearings offer a cost-effective solution for heavy-duty performance and longer lifespan under continuous operation.

Typical Uses for Ball Bearings

Ball bearings are commonly used in applications requiring low friction and high-speed rotation, such as electric motors, automotive wheels, and industrial machinery. Their design supports both radial and axial loads, making them ideal for precision equipment like hard drives and aerospace components. In contrast to plain bearings, ball bearings provide better performance in environments where reduced wear and maintenance are essential.

Selecting the Right Bearing for Your Needs

Plain bearings offer low friction and simple design ideal for applications with oscillating or slow rotary motion, while ball bearings provide higher precision and support radial and axial loads for faster rotational speeds. Selecting the right bearing depends on factors such as load capacity, speed requirements, maintenance intervals, and environmental conditions. Considering wear resistance, lubrication needs, and cost-effectiveness ensures optimal performance and longevity in your specific application.

Maintenance and Lifespan Considerations

Plain bearings require regular lubrication to minimize friction and wear, with maintenance intervals depending on operating conditions and load; neglect can lead to surface damage and reduced lifespan. Ball bearings, typically sealed and pre-lubricated, demand less frequent maintenance but monitoring for noise and vibration is crucial to identify early signs of failure. Lifespan of plain bearings is often shorter under high-speed or heavy-load conditions, whereas ball bearings generally provide longer service life with proper maintenance in moderate to high-speed applications.

Plain bearings Infographic

libterm.com

libterm.com