Just-in-time manufacturing minimizes inventory costs by producing goods only as needed, enhancing efficiency and reducing waste in the production process. This approach relies on precise demand forecasting and seamless supplier coordination to maintain a smooth workflow. Discover how adopting just-in-time manufacturing can transform your operations and boost productivity in the rest of this article.

Table of Comparison

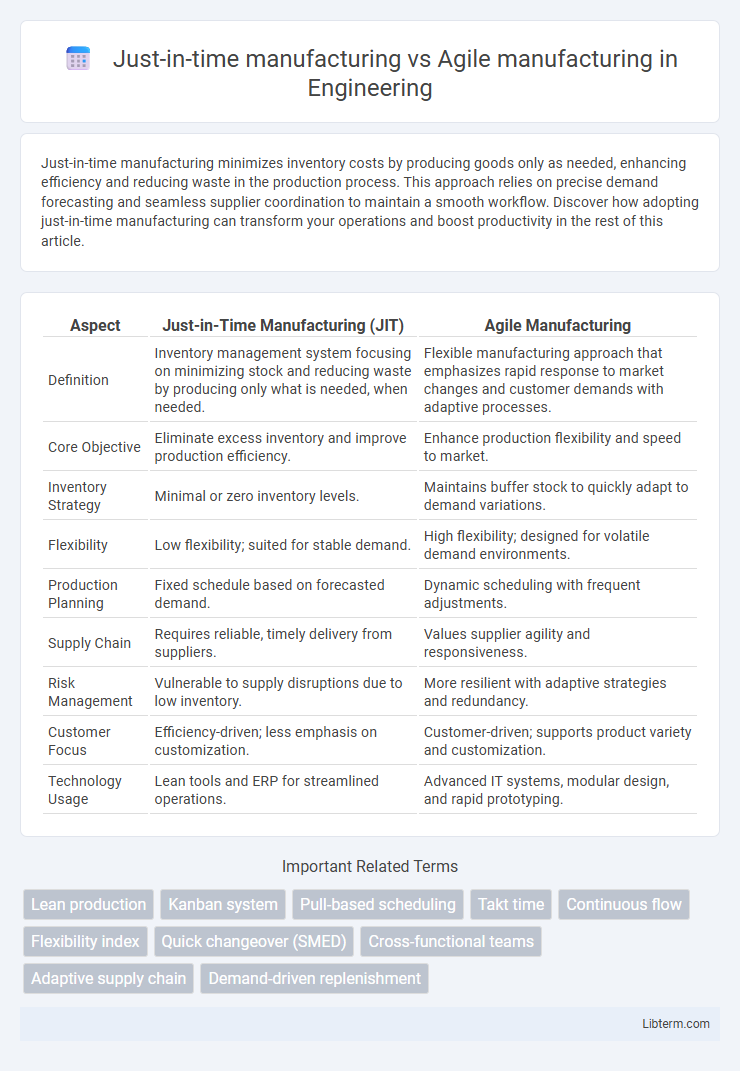

| Aspect | Just-in-Time Manufacturing (JIT) | Agile Manufacturing |

|---|---|---|

| Definition | Inventory management system focusing on minimizing stock and reducing waste by producing only what is needed, when needed. | Flexible manufacturing approach that emphasizes rapid response to market changes and customer demands with adaptive processes. |

| Core Objective | Eliminate excess inventory and improve production efficiency. | Enhance production flexibility and speed to market. |

| Inventory Strategy | Minimal or zero inventory levels. | Maintains buffer stock to quickly adapt to demand variations. |

| Flexibility | Low flexibility; suited for stable demand. | High flexibility; designed for volatile demand environments. |

| Production Planning | Fixed schedule based on forecasted demand. | Dynamic scheduling with frequent adjustments. |

| Supply Chain | Requires reliable, timely delivery from suppliers. | Values supplier agility and responsiveness. |

| Risk Management | Vulnerable to supply disruptions due to low inventory. | More resilient with adaptive strategies and redundancy. |

| Customer Focus | Efficiency-driven; less emphasis on customization. | Customer-driven; supports product variety and customization. |

| Technology Usage | Lean tools and ERP for streamlined operations. | Advanced IT systems, modular design, and rapid prototyping. |

Introduction to Just-in-Time (JIT) and Agile Manufacturing

Just-in-Time (JIT) manufacturing emphasizes minimizing inventory by receiving goods only as they are needed in the production process, which reduces waste and improves efficiency. Agile manufacturing focuses on flexibility and quick response to market changes by integrating adaptive processes and technologies. Both methodologies aim to enhance production efficiency, but JIT centers on inventory control while Agile manufacturing prioritizes responsiveness and customization.

Core Principles of Just-in-Time Manufacturing

Just-in-time (JIT) manufacturing emphasizes minimizing inventory levels by producing only what is needed, when it is needed, to reduce waste and improve efficiency. Core principles include continuous flow, pull production systems based on actual demand, and rigorous quality control to prevent defects. This contrasts with agile manufacturing, which prioritizes flexibility and rapid response to market changes over strict inventory control.

Key Concepts of Agile Manufacturing

Agile manufacturing emphasizes flexibility, rapid responsiveness, and collaboration across the supply chain to adapt quickly to market changes and customer demands. It integrates advanced technologies, cross-functional teams, and real-time data analytics to enhance product customization and reduce lead times. This contrasts with just-in-time manufacturing, which primarily focuses on minimizing inventory and waste through precise production scheduling.

Efficiency and Flexibility: Comparing JIT and Agile Approaches

Just-in-time (JIT) manufacturing emphasizes efficiency by minimizing inventory levels and reducing waste through precise demand synchronization, which leads to lower holding costs and streamlined production processes. Agile manufacturing prioritizes flexibility, enabling rapid adaptation to market changes and customized product offerings while maintaining responsiveness across the supply chain. Comparing the two, JIT excels in cost efficiency and lean operations, whereas Agile manufacturing delivers superior flexibility and responsiveness in dynamic environments.

Inventory Management Differences: JIT vs Agile

Just-in-time (JIT) manufacturing emphasizes minimizing inventory levels by receiving materials only as they are needed in the production process, reducing holding costs and waste. Agile manufacturing maintains a more flexible inventory strategy, balancing readiness with responsiveness to quickly adapt to market changes and customer demands. While JIT focuses on efficiency through tight inventory control, Agile prioritizes inventory adaptability to support rapid production shifts.

Impact on Supply Chain Optimization

Just-in-time manufacturing reduces inventory holding costs and enhances supply chain responsiveness by synchronizing production with demand, minimizing waste and storage needs. Agile manufacturing emphasizes flexibility and quick adaptation to market changes, enabling supply chains to handle variability and customize products efficiently. Combining both approaches optimizes supply chain performance by balancing cost efficiency with responsiveness and customization capabilities.

Response to Market Changes and Customer Demands

Just-in-time manufacturing minimizes inventory and reduces waste by producing goods only as needed, enabling quick adaptation to specific customer orders but with limited flexibility during sudden market shifts. Agile manufacturing emphasizes adaptability and rapid reconfiguration of production lines, allowing companies to respond swiftly to unpredictable market changes and evolving customer demands. Both approaches enhance responsiveness, but agile manufacturing offers superior flexibility in dynamic environments, while just-in-time excels in efficiency for consistent demand.

Technology Integration in JIT and Agile Systems

Just-in-time (JIT) manufacturing leverages real-time inventory tracking systems and automated supply chain management to minimize waste and ensure materials arrive precisely when needed, optimizing production efficiency. Agile manufacturing integrates advanced technologies such as IoT sensors, AI-driven analytics, and flexible robotics to rapidly adapt to changing customer demands and customize products without disrupting workflows. Both systems use digital platforms for seamless communication and data sharing between suppliers, production teams, and distribution channels, enhancing responsiveness and reducing lead times.

Real-World Case Studies: Successes and Challenges

Toyota's implementation of Just-in-Time (JIT) manufacturing dramatically reduced inventory costs and lead times, showcasing the system's efficiency in minimizing waste, but faced challenges in supply chain disruptions during natural disasters. Conversely, Zara's Agile manufacturing approach enables rapid product turnover by integrating real-time customer data and flexible production, successfully responding to fast fashion trends while managing the complexity of frequent design changes. Both models reveal that while JIT excels in cost efficiency and lean inventory, Agile manufacturing offers superior adaptability, though each demands robust supply chain coordination to mitigate risks.

Choosing the Right Approach for Your Manufacturing Needs

Choosing the right manufacturing approach depends on your production volume and market variability; Just-in-Time (JIT) manufacturing excels in reducing inventory costs through precise demand forecasting and minimizing waste in stable environments. Agile manufacturing prioritizes flexibility and responsiveness, enabling rapid adaptation to customer demands and design changes, making it ideal for industries with high customization or fluctuating orders. Evaluating factors such as lead time, production complexity, and supply chain reliability will help determine whether JIT's efficiency or Agile's adaptability best aligns with your business objectives.

Just-in-time manufacturing Infographic

libterm.com

libterm.com