A fillet is a boneless cut of meat or fish known for its tenderness and versatility in cooking. Properly filleted fish or meat enhances your dishes by providing a smooth texture and quick cooking time. Explore the rest of this article to master the art of filleting and elevate your culinary skills.

Table of Comparison

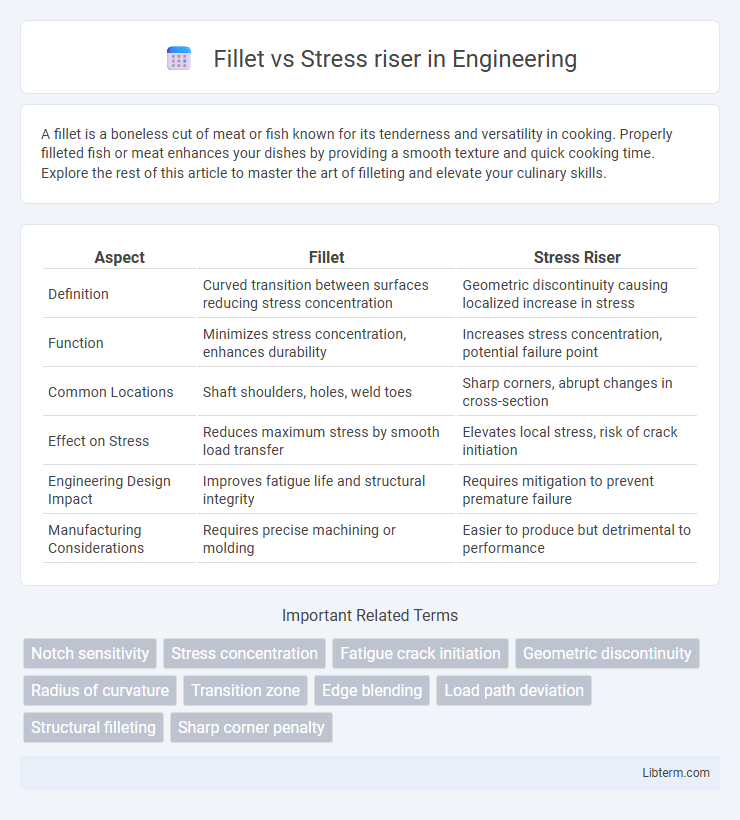

| Aspect | Fillet | Stress Riser |

|---|---|---|

| Definition | Curved transition between surfaces reducing stress concentration | Geometric discontinuity causing localized increase in stress |

| Function | Minimizes stress concentration, enhances durability | Increases stress concentration, potential failure point |

| Common Locations | Shaft shoulders, holes, weld toes | Sharp corners, abrupt changes in cross-section |

| Effect on Stress | Reduces maximum stress by smooth load transfer | Elevates local stress, risk of crack initiation |

| Engineering Design Impact | Improves fatigue life and structural integrity | Requires mitigation to prevent premature failure |

| Manufacturing Considerations | Requires precise machining or molding | Easier to produce but detrimental to performance |

Introduction to Fillet and Stress Riser

A fillet is a rounded internal corner or edge designed to reduce stress concentration in a material by distributing load more evenly. Stress risers are sharp notches, grooves, or abrupt changes in geometry that cause localized increases in stress, often leading to failure initiation. Incorporating fillets in design minimizes the impact of stress risers, enhancing component durability and fatigue resistance.

Definition of Fillet in Engineering

A fillet in engineering refers to the rounded transition between two surfaces, typically at an interior corner, designed to reduce stress concentration and improve load distribution. This smooth curve replaces a sharp corner to minimize stress risers that can cause crack initiation and fatigue failure. Properly dimensioned fillets enhance structural integrity by lowering localized stresses in components subjected to bending, torsion, or tensile loads.

Understanding Stress Risers

Stress risers are localized points in a material where stress is significantly higher due to sudden changes in geometry or discontinuities such as notches, holes, or sharp corners. Fillets reduce stress risers by providing a smooth transition between surfaces, minimizing stress concentration and enhancing durability. Understanding stress risers is crucial in mechanical design to prevent failure and optimize structural integrity.

Causes of Stress Concentration

Stress concentration often arises at geometric discontinuities where abrupt changes in shape or cross-sectional area occur, such as sharp corners or notches, known as stress risers. Fillets, which are smooth rounded transitions between surfaces, reduce stress concentration by distributing stress more evenly around these discontinuities. The primary cause of stress concentration is the presence of these sudden changes in geometry that interrupt the uniform flow of stress, increasing localized stress intensity.

Effects of Fillets on Stress Distribution

Fillets significantly reduce stress concentration by smoothing sharp corners and redistributing load more evenly across the material, minimizing the risk of crack initiation. Stress risers, typically sharp notches or abrupt changes in geometry, create localized areas of high stress that can lead to premature material failure. By introducing fillets in design, engineers enhance fatigue life and structural integrity by lowering peak stress intensity factors at critical points.

Comparing Fillet vs Stress Riser: Key Differences

Fillets are smooth rounded transitions between surfaces designed to reduce stress concentration, while stress risers are sharp notches or discontinuities that amplify localized stress. Fillets distribute stress evenly by eliminating abrupt changes in geometry, which decreases the likelihood of material failure. Stress risers create points of weakness where cracks can initiate and propagate, significantly impacting the mechanical performance and durability of engineering components.

Design Guidelines to Minimize Stress Risers

Design guidelines to minimize stress risers emphasize incorporating fillets at sharp corners to distribute stress more evenly and reduce localized concentrations that lead to material failure. Selecting appropriate fillet radii based on the thickness and load conditions of the component ensures smoother transitions and enhances fatigue resistance. Using finite element analysis (FEA) to optimize fillet dimensions can further improve stress distribution and structural integrity in mechanical designs.

Applications of Fillets in Structural Design

Fillets are crucial in structural design for reducing stress concentrations by smoothing sharp corners and transitions, enhancing component durability and fatigue resistance. Their application is common in aerospace, automotive, and mechanical engineering to improve load distribution and prevent crack initiation at stress risers. Incorporating fillets in joints, holes, and bends ensures structural integrity and prolongs the lifespan of critical parts under dynamic loads.

Common Mistakes: Fillet Selection and Placement

Incorrect fillet selection often involves choosing a radius too small to sufficiently reduce stress concentration, leading to premature component failure. Improper placement, such as positioning fillets away from critical load paths or sharp corners, can negate their intended stress-relieving effect. Neglecting to match fillet size to the material's mechanical properties and expected load conditions results in ineffective stress riser mitigation.

Best Practices for Enhancing Component Durability

Fillet designs reduce stress concentrations by providing smooth transitions between surfaces, which enhances component durability by evenly distributing loads and minimizing crack initiation sites. Stress risers, often caused by sharp corners or notches, act as focal points for stress accumulation and significantly increase the risk of material failure under cyclic loading. Implementing optimized fillet radii and avoiding abrupt geometric changes are critical best practices for mitigating stress risers and prolonging the lifespan of mechanical components.

Fillet Infographic

libterm.com

libterm.com