Bending capacity measures the maximum moment a structural element can resist before failure occurs due to bending stress. It's essential for designing beams and slabs to ensure safety and durability in construction projects. Explore the rest of this article to understand how bending capacity affects your structural design choices.

Table of Comparison

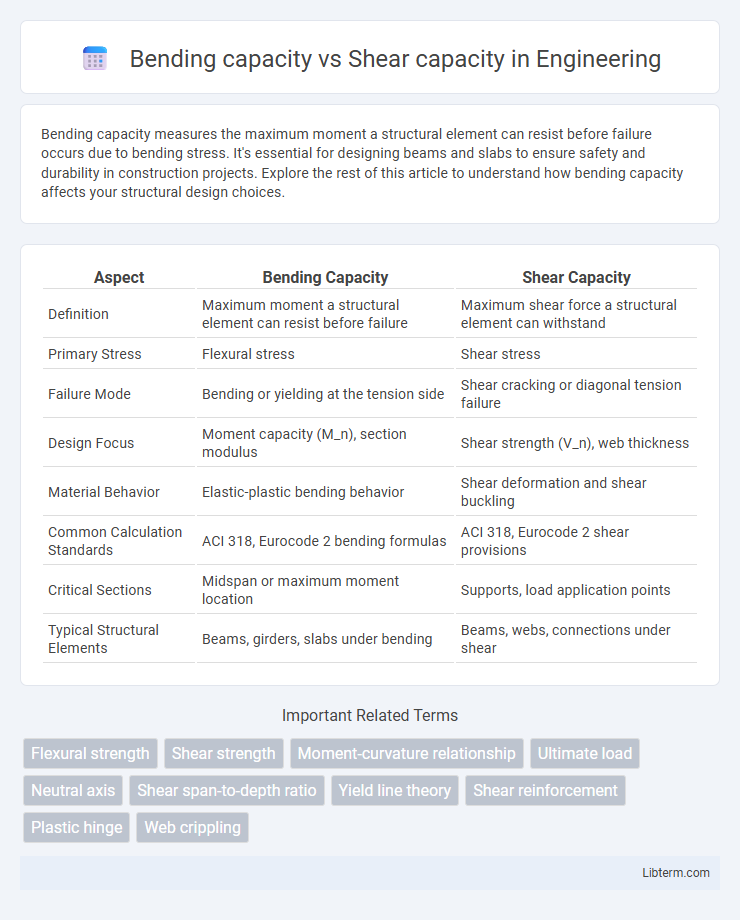

| Aspect | Bending Capacity | Shear Capacity |

|---|---|---|

| Definition | Maximum moment a structural element can resist before failure | Maximum shear force a structural element can withstand |

| Primary Stress | Flexural stress | Shear stress |

| Failure Mode | Bending or yielding at the tension side | Shear cracking or diagonal tension failure |

| Design Focus | Moment capacity (M_n), section modulus | Shear strength (V_n), web thickness |

| Material Behavior | Elastic-plastic bending behavior | Shear deformation and shear buckling |

| Common Calculation Standards | ACI 318, Eurocode 2 bending formulas | ACI 318, Eurocode 2 shear provisions |

| Critical Sections | Midspan or maximum moment location | Supports, load application points |

| Typical Structural Elements | Beams, girders, slabs under bending | Beams, webs, connections under shear |

Introduction to Bending and Shear Capacities

Bending capacity refers to the maximum moment a structural member can resist before failure, determined by the flexural strength of the material and the cross-sectional properties. Shear capacity is the ability of the member to withstand transverse forces that cause shear deformation or failure, largely dependent on shear strength and web dimensions. Accurate assessment of both bending and shear capacities is crucial for ensuring structural safety and performance under applied loads.

Fundamental Concepts of Structural Capacity

Bending capacity refers to a structural element's ability to resist moments causing bending without failure, primarily governed by the material strength and cross-sectional geometry. Shear capacity is the maximum shear force a member can sustain before shear failure occurs, influenced by shear area and material shear strength. Understanding both capacities is crucial for ensuring structural safety, as bending and shear stresses must be evaluated independently and collectively to prevent structural collapse.

Understanding Bending Capacity in Structural Elements

Bending capacity in structural elements refers to the maximum moment a beam or slab can resist before failure, primarily influenced by material strength, cross-sectional geometry, and reinforcement layout. It ensures that the element can support applied loads without excessive deformation or cracking due to bending stresses. Evaluating bending capacity involves calculating the moment of resistance based on stress distribution, which is critical for safe and efficient structural design.

Shear Capacity: Definition and Significance

Shear capacity refers to the maximum shear force a structural element can resist before failure occurs, critical in ensuring safety against diagonal cracking and sudden shear collapse. It depends on factors such as material strength, cross-sectional area, and the presence of shear reinforcement like stirrups in beams. Understanding and designing for adequate shear capacity prevents structural instability and enhances overall load-bearing performance in construction engineering.

Key Differences Between Bending and Shear Capacities

Bending capacity refers to a structural member's ability to resist moments causing it to bend without failure, primarily influenced by material strength, cross-sectional shape, and moment arm. Shear capacity measures the maximum shear force a member can sustain before shear failure occurs, largely dependent on web thickness, shear area, and shear strength of the material. Key differences include bending capacity relating to flexural stress distribution and moment resistance, while shear capacity focuses on resisting transverse shear forces and preventing shear cracks or sliding failure.

Factors Influencing Bending Capacity

Bending capacity depends on material properties, cross-sectional shape, and moment of inertia, which influence the beam's resistance to bending moments. The modulus of elasticity and yield strength determine the elastic and plastic behavior under bending loads, while the beam's depth and width significantly affect its moment capacity. Shear capacity, in contrast, is governed by the material's shear strength and the web thickness of structural members, but bending capacity primarily hinges on geometric and mechanical factors that control flexural stress distribution.

Determinants of Shear Capacity

Shear capacity is primarily determined by the material strength, cross-sectional geometry, and the presence of web reinforcements such as stirrups. Factors like the shear span-to-depth ratio and loading conditions also significantly influence the shear capacity of structural elements. Contrastingly, bending capacity depends more on flexural reinforcement and moment resistance, highlighting the distinct determinants influencing these two critical structural responses.

Methods for Calculating Bending and Shear Capacities

Methods for calculating bending capacity typically involve analyzing the moment-curvature relationship of beams using the flexural formula, which incorporates material yield strength, cross-sectional geometry, and neutral axis location. Shear capacity calculation relies on evaluating shear stresses considering shear flow, web thickness, and reinforcement layout according to standards like AISC or Eurocode. Advanced techniques such as finite element analysis enhance accuracy by simulating stress distribution under complex loading conditions in both bending and shear scenarios.

Practical Examples: Bending vs Shear Failure

Bending capacity refers to a beam's ability to resist bending moments causing compression and tension, while shear capacity relates to resisting transverse forces that cause sliding failure along a plane. Practical examples show bending failure in beams occurs when excessive load causes visible deflection and cracks at the tension face, such as in over-spanned floor joists. Shear failure typically manifests near the supports in the form of sudden diagonal cracks and brittle fracture, common in short beams under heavy concentrated loads.

Design Considerations for Bending and Shear in Structures

Design considerations for bending capacity focus on the ability of structural elements to resist moments causing tension and compression, ensuring adequate flexural strength and preventing excessive deflection or cracking. Shear capacity design addresses the element's resistance to shear forces that can cause diagonal tension failure or web shear cracking, emphasizing the need for proper shear reinforcement and concrete strength. Both capacities are critical for structural safety, requiring careful analysis of load combinations, material properties, and cross-sectional dimensions to optimize durability and performance.

Bending capacity Infographic

libterm.com

libterm.com