A piston gauge accurately measures pressure by balancing a known weight on a piston, ensuring precise calibration for various applications. This device is essential for industries requiring reliable pressure standards and helps maintain system integrity. Discover how a piston gauge can enhance Your measurements by reading the full article.

Table of Comparison

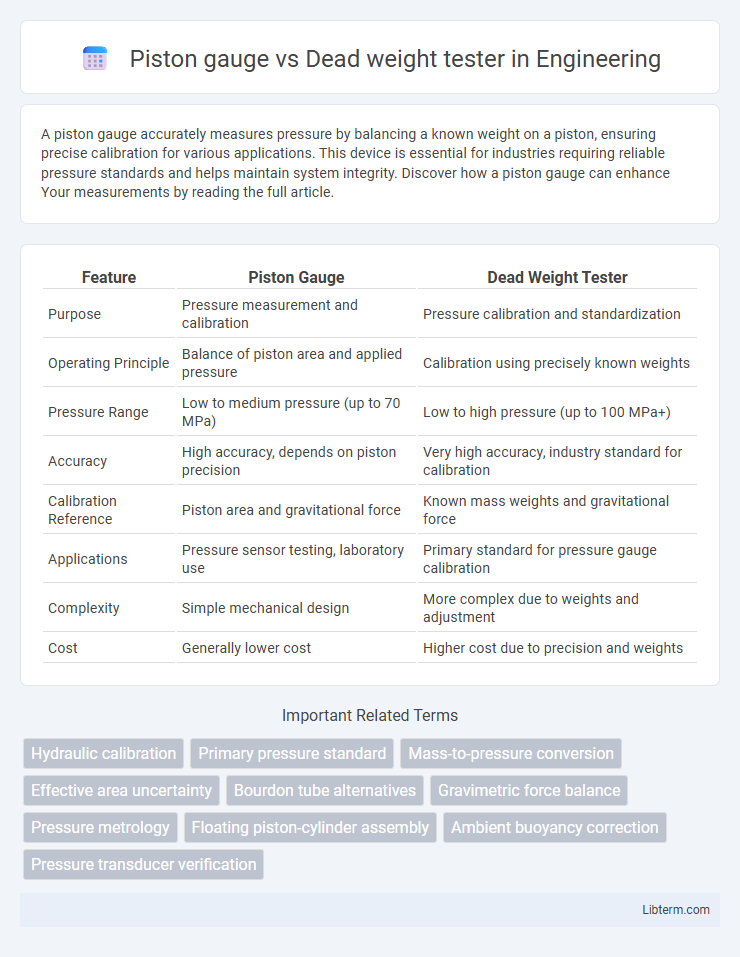

| Feature | Piston Gauge | Dead Weight Tester |

|---|---|---|

| Purpose | Pressure measurement and calibration | Pressure calibration and standardization |

| Operating Principle | Balance of piston area and applied pressure | Calibration using precisely known weights |

| Pressure Range | Low to medium pressure (up to 70 MPa) | Low to high pressure (up to 100 MPa+) |

| Accuracy | High accuracy, depends on piston precision | Very high accuracy, industry standard for calibration |

| Calibration Reference | Piston area and gravitational force | Known mass weights and gravitational force |

| Applications | Pressure sensor testing, laboratory use | Primary standard for pressure gauge calibration |

| Complexity | Simple mechanical design | More complex due to weights and adjustment |

| Cost | Generally lower cost | Higher cost due to precision and weights |

Introduction to Pressure Measurement Tools

Piston gauges and dead weight testers are precise pressure measurement tools commonly used for calibration and verification in industrial and laboratory settings. Piston gauges measure pressure by balancing a known weight on a piston, directly relating mechanical force to pressure, while dead weight testers apply known weights on a piston-cylinder assembly to generate a reference pressure. Both instruments provide high accuracy and are essential for maintaining pressure measurement standards and ensuring the reliability of pressure sensors and gauges.

What is a Piston Gauge?

A piston gauge is a precision pressure measurement device that balances a known weight on a piston to generate a highly accurate pressure reference. It operates by applying gravitational force to a piston of known cross-sectional area, creating a pressure that can be measured against an unknown pressure source. Compared to dead weight testers, piston gauges offer improved sensitivity and are commonly used for calibrating pressure instruments in laboratories and industrial settings.

What is a Dead Weight Tester?

A Dead Weight Tester is a precision instrument used to calibrate pressure measuring devices by applying known weights to generate a standard pressure. Unlike a piston gauge that relies on the physical dimensions of a piston-cylinder assembly and atmospheric pressure, the Dead Weight Tester uses traceable weights to produce highly accurate and stable pressure values. This method ensures reliable calibration of pressure sensors, manometers, and gauges across a wide range of applications.

Working Principle: Piston Gauge vs Dead Weight Tester

The working principle of a piston gauge relies on balancing the force exerted by a known weight on a piston against the pressure of the fluid, where the pressure is determined by the ratio of the weight to the piston's cross-sectional area. In contrast, a dead weight tester uses calibrated weights placed on a piston to generate a precise pressure, which is measured when the piston is in equilibrium with the applied pressure. Both devices provide highly accurate pressure calibration by correlating mechanical forces with fluid pressure, but the piston gauge often integrates into automated systems, while the dead weight tester is primarily a manual standard for calibration labs.

Accuracy Comparison: Piston Gauge and Dead Weight Tester

Piston gauges and dead weight testers both measure pressure with high accuracy, but dead weight testers typically provide superior precision due to their direct reliance on calibrated weights. The accuracy of a piston gauge depends on factors like piston-cylinder clearance and temperature stability, often yielding slightly less consistent results than dead weight testers. Dead weight testers achieve measurement uncertainty as low as +-0.01%, making them the preferred choice for primary pressure calibration standards.

Calibration Procedures for Both Devices

Piston gauges calibrate pressure by balancing a known mass against a piston area under test conditions, requiring precise mass selection and environmental controls to ensure accuracy. Dead weight testers perform calibration by applying standard weights to a piston-cylinder assembly, generating reference pressures that must be verified against traceable standards with careful alignment and clean surfaces. Both devices demand systematic procedures including zeroing, leak checks, and incremental loading to achieve reliable calibration results in pressure measurement.

Advantages and Limitations of Piston Gauges

Piston gauges offer high accuracy and stability for pressure measurement, particularly in calibrating other instruments by providing reliable reference pressures based on precise mass and area calibration. They are limited by their sensitivity to environmental conditions such as temperature and vibration, which can affect measurement accuracy, and their operational complexity requiring skilled handling. Unlike dead weight testers, piston gauges are more compact and portable but generally have a narrower pressure range and require careful maintenance to ensure consistent performance.

Pros and Cons of Dead Weight Testers

Dead weight testers offer high accuracy and traceability for pressure calibration, making them ideal for laboratory standards and precision instruments. However, they require regular maintenance and careful handling of weights to avoid measurement errors and can be bulky compared to piston gauges. Their reliance on gravity and mechanical components limits portability but ensures stable and repeatable pressure references.

Typical Applications: Piston Gauge vs Dead Weight Tester

Piston gauges are primarily used for precise pressure calibration in laboratory and industrial environments requiring high accuracy at low to medium pressure ranges. Dead weight testers excel in generating highly accurate reference pressures by applying calibrated weights, making them ideal for calibrating pressure instruments in high-pressure ranges and quality control settings. Both devices serve critical roles in pressure measurement calibration, with piston gauges favored for direct pressure measurement and dead weight testers preferred for their robustness in traceable pressure generation.

Choosing the Right Instrument for Your Needs

Piston gauges provide high-accuracy pressure calibration using a known weight and piston area, ideal for precise laboratory measurements requiring stable reference pressures. Dead weight testers offer versatility with multiple interchangeable weights and are suitable for field calibration and routine maintenance checks where portability and ease of use are crucial. Selecting the right instrument depends on the required pressure range, accuracy level, and operational environment, ensuring optimal performance and reliability.

Piston gauge Infographic

libterm.com

libterm.com